Knuckle bearing tip iron

A joint bearing, cutting-edge technology, applied in the field of installation devices for high-speed, speed-up, and heavy-duty railway external locking turnouts, can solve the problems of increased resistance, easy jamming, and inconvenient adjustment, so as to reduce conversion resistance and facilitate On-site adjustment and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

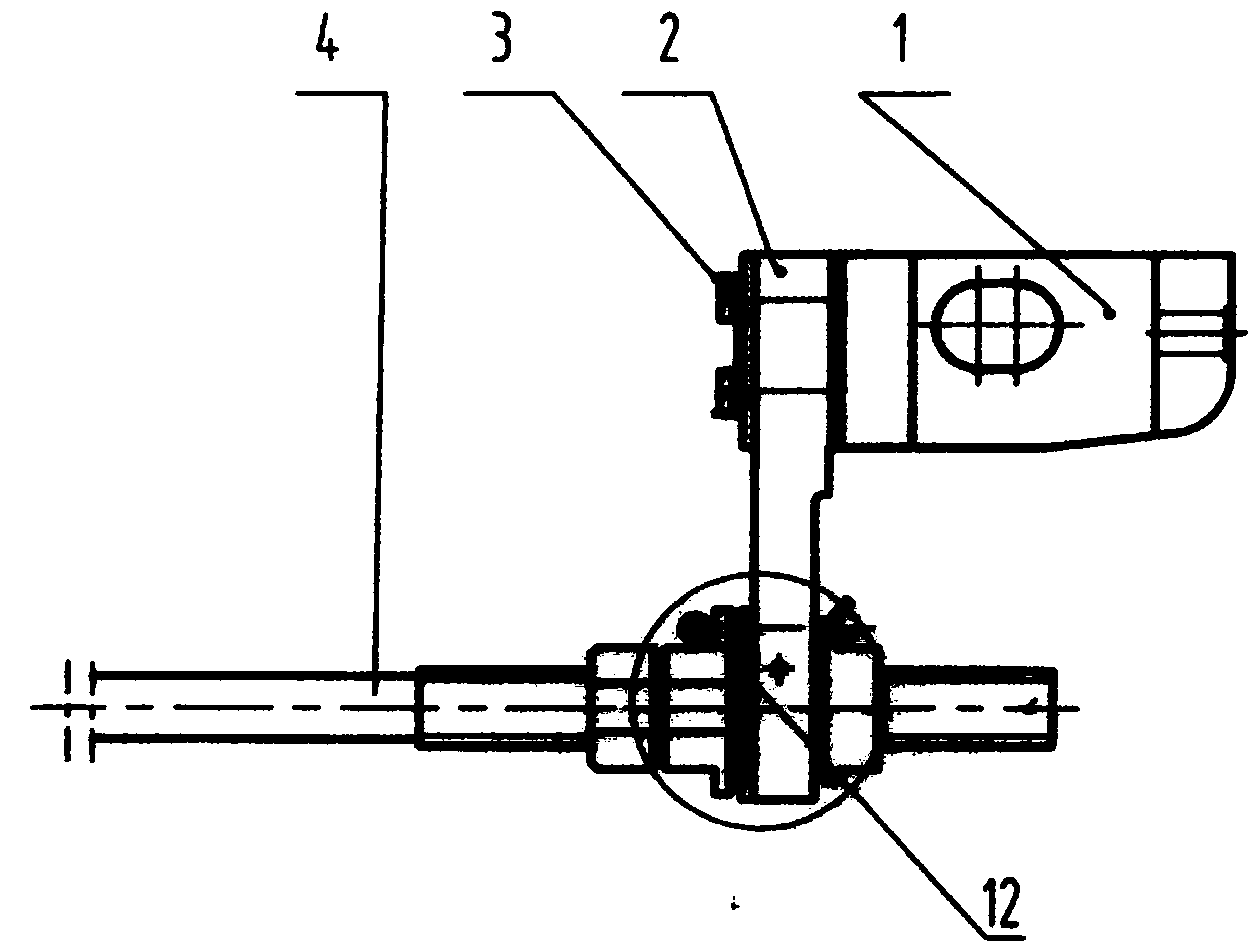

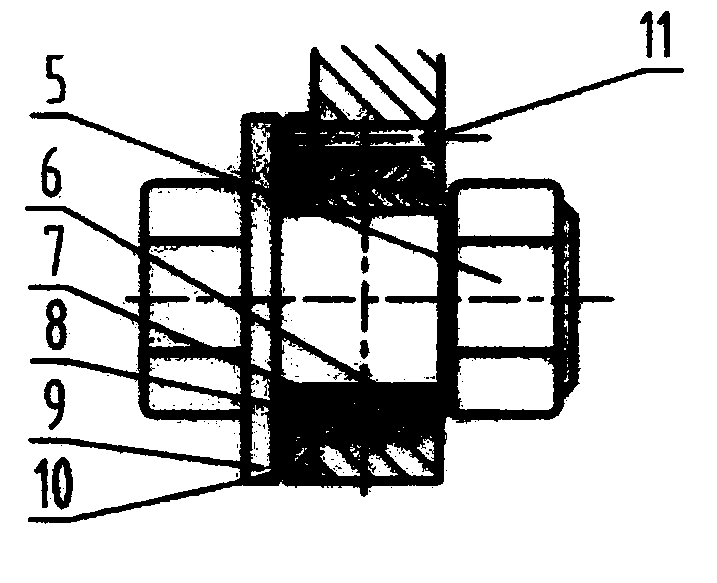

[0015] The embodiment of the point iron of the joint bearing of the present invention will be further described in detail below in conjunction with the accompanying drawings: a point iron of the joint bearing, which is composed of a point iron, a display joint plate, etc., is characterized in that: the point iron 1 and the display joint plate 2 are installed There is a V-shaped insulation 3, indicating that the connection hole of the joint plate 2 has a joint bearing composed of an inner ring 7 and an outer ring 8, and the outer ring 8 is transitionally fitted with the joint plate 2, and a baffle 10 is installed on one side, and the baffle 10 and the The indication joint plate 2 is riveted with rivets 11, and the outer ring 8 is assisted in positioning. The retaining ring 6 is installed on both sides of the outer ring 8, and the shaft sleeve 9 and the nut 5 are installed on both sides of the inner ring 7. The indication rod 4 is adjusted to form a joint bearing. Tip iron. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com