Anti-eccentric load guide structure

A guiding structure and anti-deflection technology, which is applied in the field of presses, can solve problems such as slider eccentricity, affecting the dimensional accuracy of forging parts and die life, and difficulty in meeting the quality requirements of precision forging products, so as to eliminate eccentricity, improve precision and mold life, and the effect of avoiding loss of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. The description herein is only used to explain the present invention when referring to specific examples, and does not limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

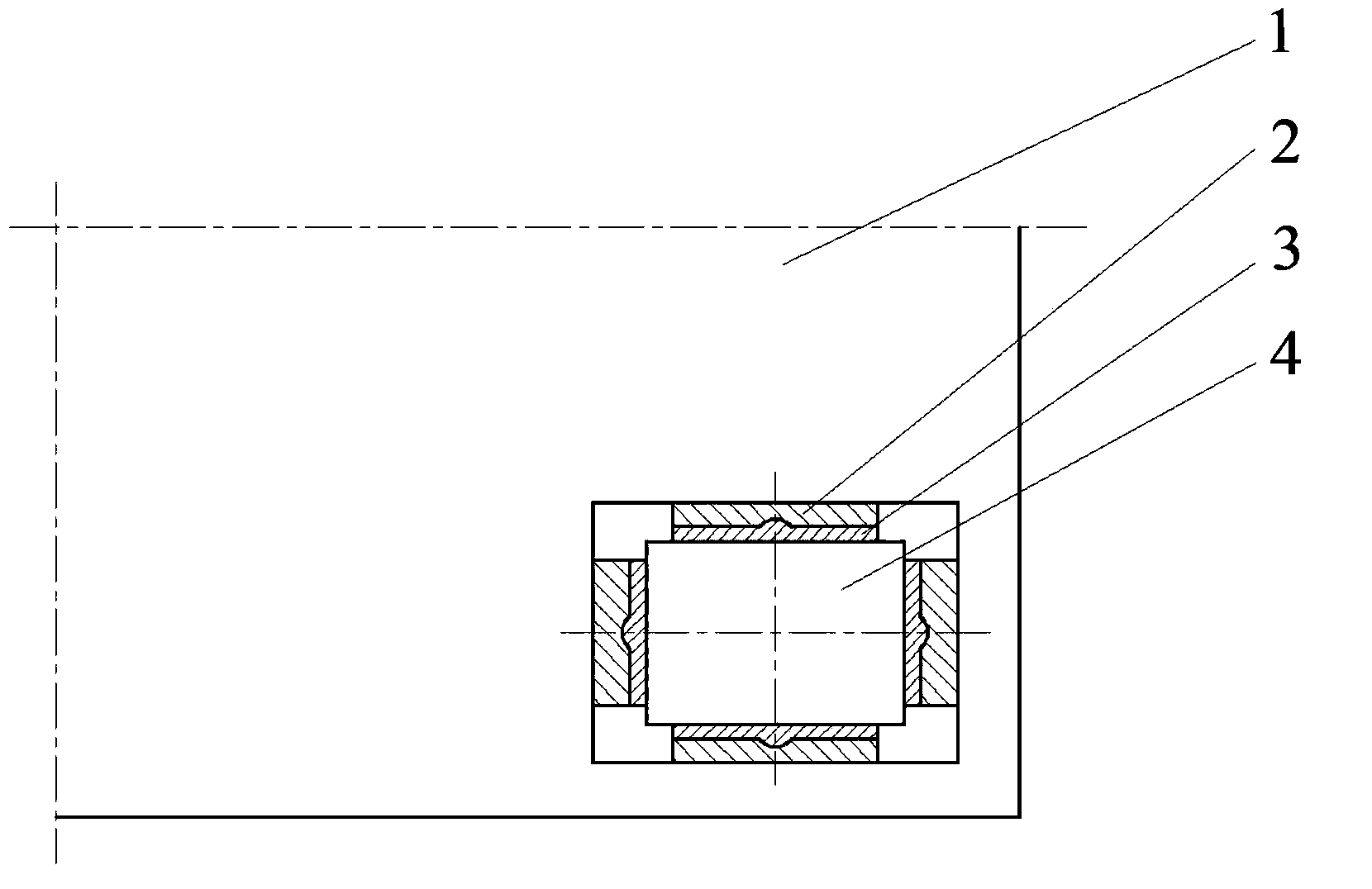

[0023] like Figure 1-3 As shown, an anti-eccentric load guiding structure according to an embodiment of the present invention includes a slider 1 , a first liner 2 , a second liner 3 and a fuselage square column 4 .

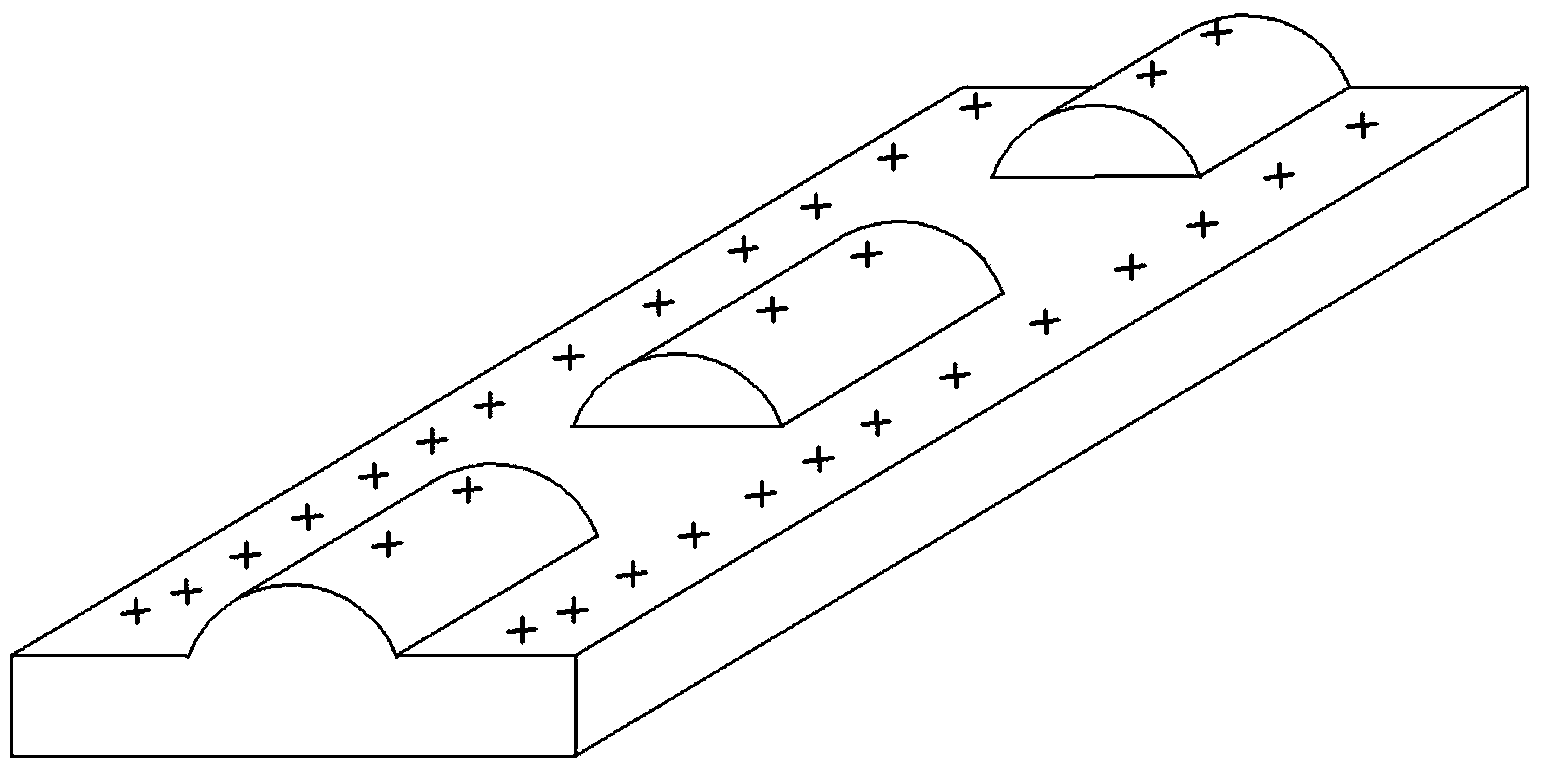

[0024] The slider 1 is fixedly connected with the pressure head of the press, and the two symmetrical corners of the slider 1 are provided with square through holes. In this embodiment, the four corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com