Double-inclined-wedge lateral punching die and punching method

A technology of lateral punching and wedge, which is applied in the field of stamping dies, can solve the problems of difficult removal of punched waste and inconvenient holding, and achieve the effect of firm fixing, convenient holding, and simple and practical punching method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

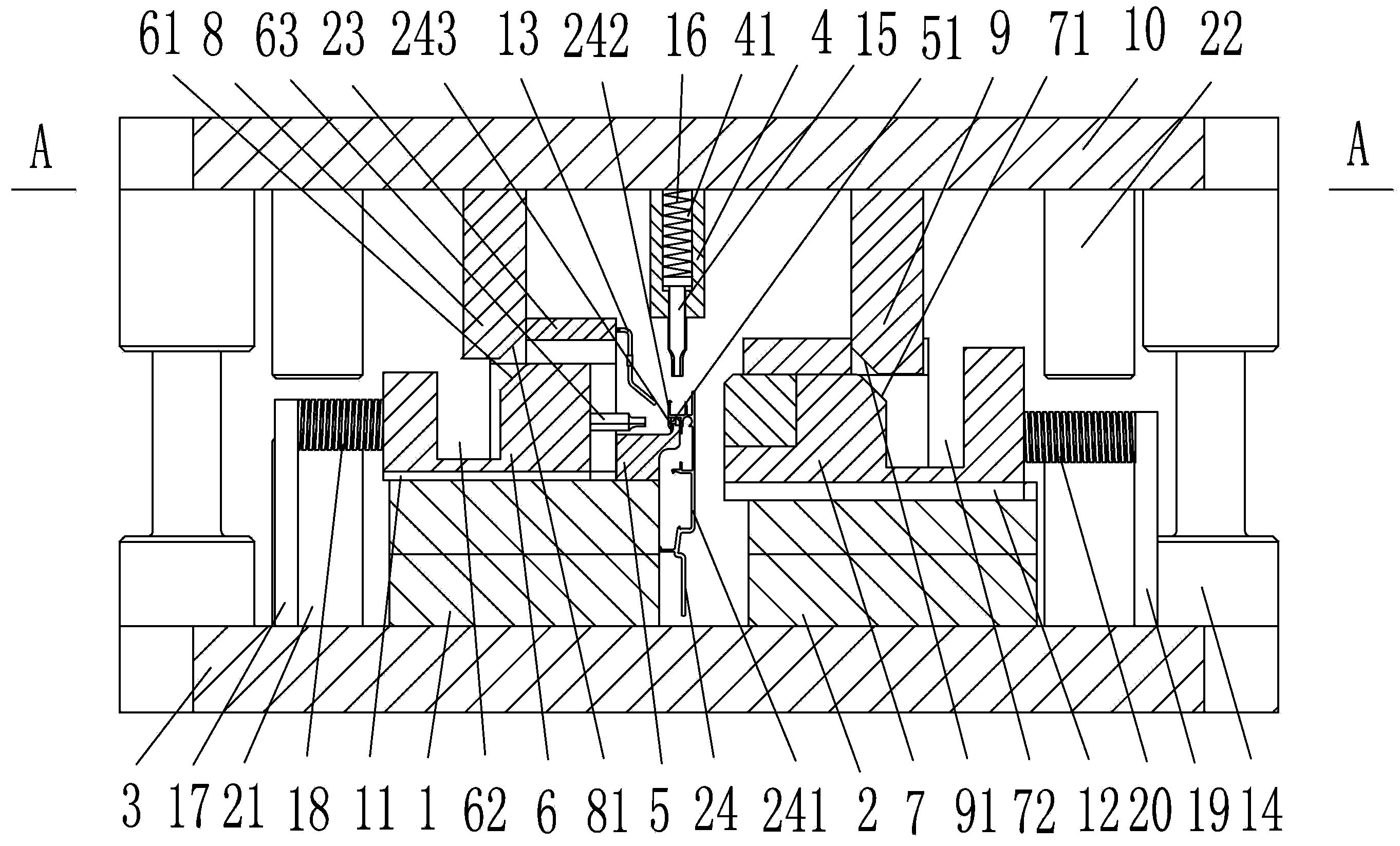

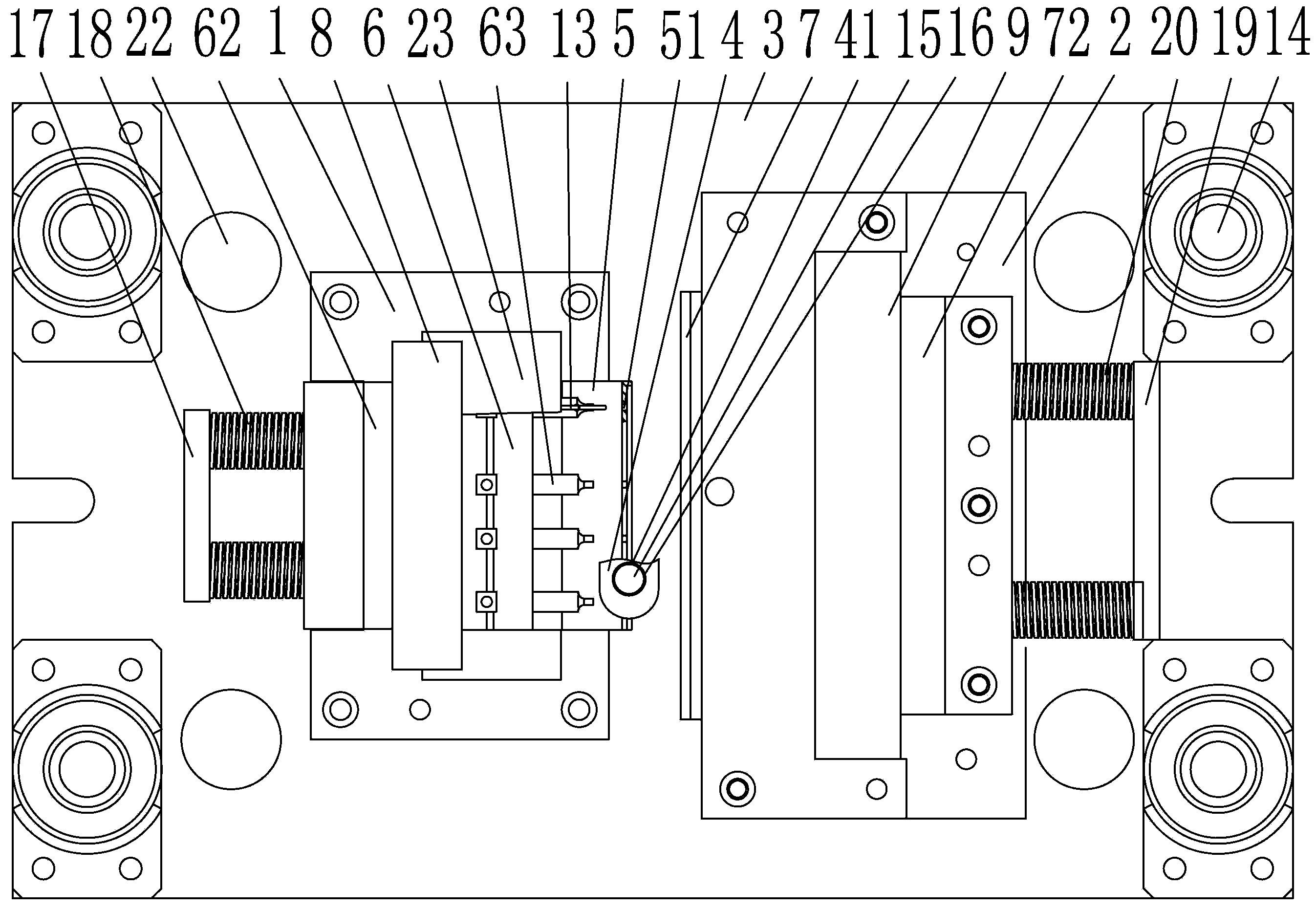

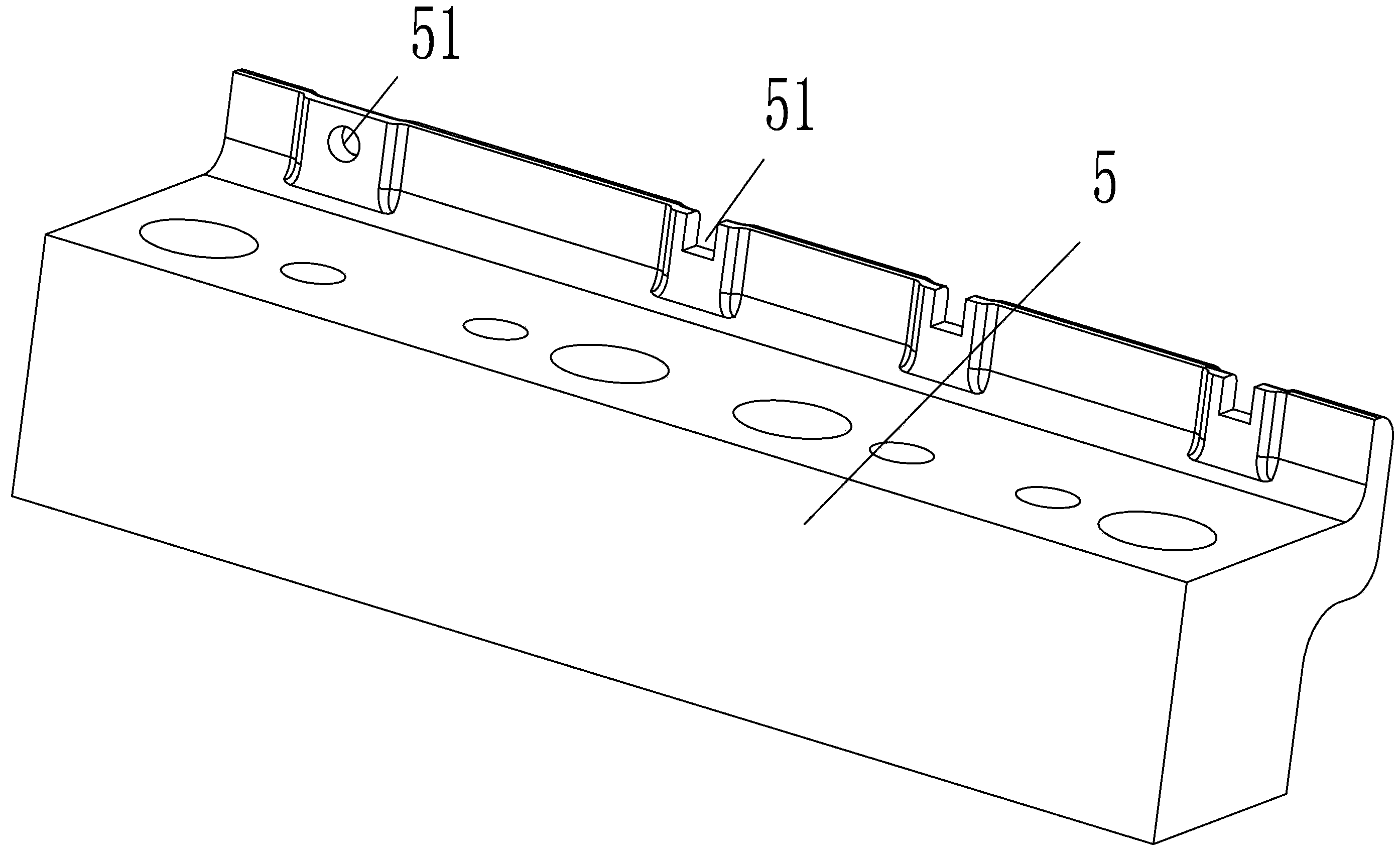

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] as attached figure 1 , attached figure 2 , attached image 3 Shown: a double wedge lateral punching die, including: the upper end has a die seat 1 and a pressing seat 2 arranged from left to right, the lower template 3 has four cutting edge holes 51 and is connected to the upper end of the die seat 1 The screw-connected die 5 is connected with the upper end of the die seat 1 through the first slide rail 11 and the right end has a punch 6 with four punches 63 equal in number to the number of cutting edge holes 51, and the upper end of the pressing seat 2 passes through The side pressing block 7 connected by the second sliding rail 12 has the upper template 10 of the first inclined wedge 8, the upper pressing head and the second inclined wedge 9 arranged from left to right at the lower end, and the outlet end is opposite to the edge hole 51 The blowing pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com