Method for fetching broken bolts from bolt holes

A technology of bolt holes and bolts, which is applied in the technical field of taking out broken bolts in mechanical equipment, can solve the problems of difficult drilling operations and difficult drilling operations, and achieve the effect of reducing the damage probability of the body thread and restoring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

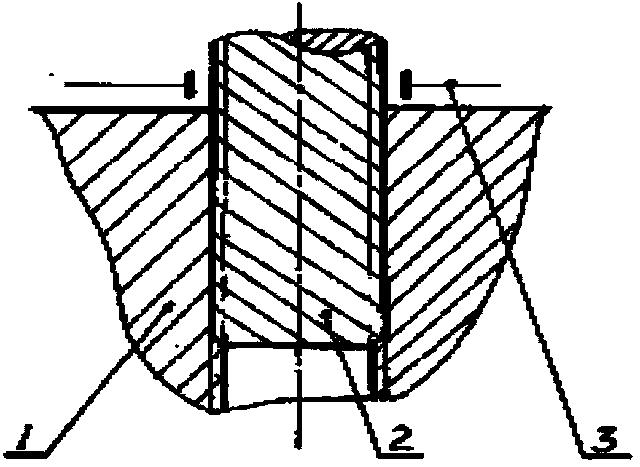

[0049] The present invention is a method for taking out a broken bolt from a bolt hole. When the section of the broken bolt is a slope with a slope, the inner diameter of the thread of the broken bolt is set to D 1 10 mm, removing the broken bolt involves the following steps:

[0050] Step (1), select the outer diameter smaller than the broken bolt thread inner diameter D 1 3 mm (the outer diameter of the steel pipe is 7 mm), the wall thickness is the inner diameter of the broken bolt thread D 1 15% of the steel pipe (that is, the outer diameter of the steel pipe is 1.5 mm), the length L of the steel pipe is taken to be 80 mm higher than the end face of the body with the bolt hole after one end of the steel pipe is in contact with the broken bolt section. length; the outer diameter of the steel pipe is set as D 2 ,D 2 ,D 2 / D 1 *100%≈70%.

[0051] Step (2), take a piece of plasticine with toughness and plasticity with a volume to fill the bolt hole and 40mm higher than ...

Embodiment 2

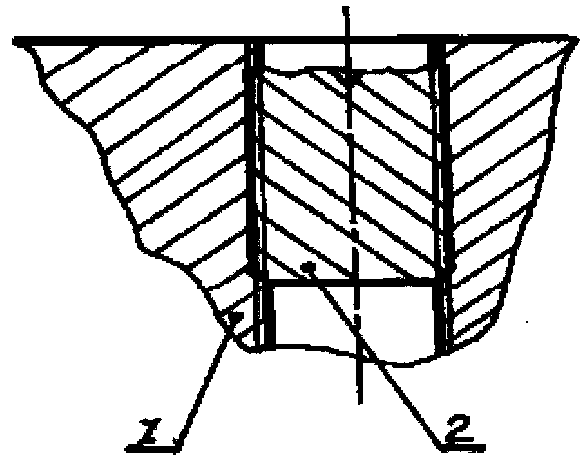

[0057] The present invention is a method for taking out a broken bolt from a bolt hole. When the section of the broken bolt is a slope with a slope, the inner diameter of the thread of the broken bolt is set to D 1 10 mm, removing the broken bolt involves the following steps:

[0058] Step (1), select the outer diameter smaller than the broken bolt thread inner diameter D 1 1 mm (the outer diameter of the steel pipe is), the wall thickness is the inner diameter of the broken bolt thread D 1 25% of the steel pipe (that is, the outer diameter of the steel pipe is 2.5 mm), the length L of the steel pipe is taken to be 80 mm higher than the end face of the body with the bolt hole after one end of the steel pipe is in contact with the broken bolt section. length; where the outer diameter of the steel pipe is set as D 2 , which satisfies D 2 / D 1 *100%≈90%;

[0059] Step (2), take a piece of plasticine with toughness and plasticity with a volume to fill the bolt hole and 60 mm...

Embodiment 3

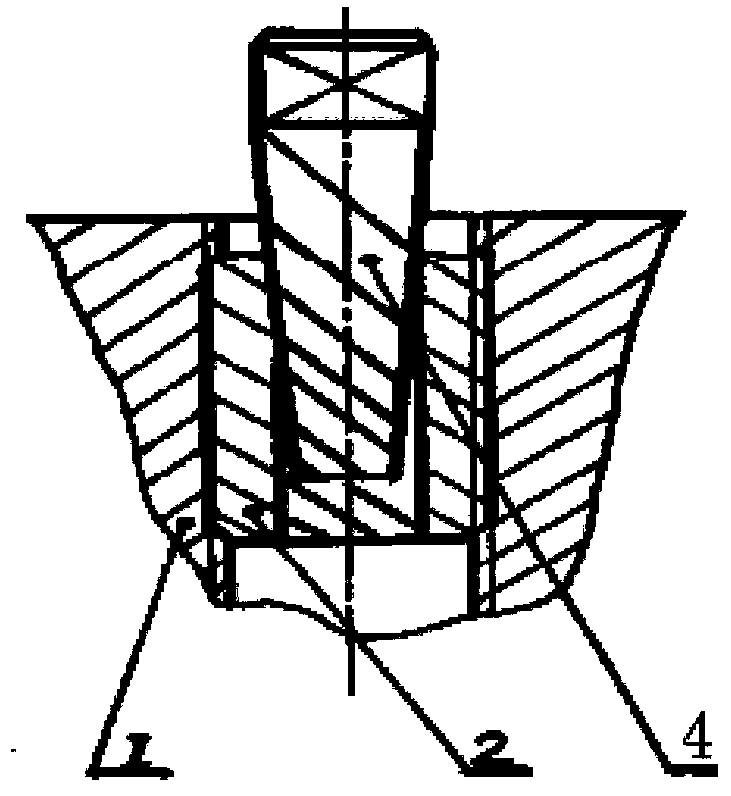

[0064] The present invention is a method for taking out a broken bolt from a bolt hole. When the section of the broken bolt is a slope with a slope, the inner diameter of the thread of the broken bolt is set to D 1 For 10 mm include the following steps:

[0065] Step (1), select the outer diameter smaller than the broken bolt thread inner diameter D 1 2 mm (the outer diameter of the steel pipe is), the wall thickness is the inner diameter of the broken bolt thread D 1 20% of the steel pipe (that is, the outer diameter of the steel pipe is 2.0 mm), the length L of the steel pipe is taken to be 100 mm higher than the end face of the body with the bolt hole after one end of the steel pipe is in contact with the broken bolt section. length; where the outer diameter of the steel pipe is set as D 2 , which satisfies D 2 / D 1 *100%≈80%;

[0066] Step (2), take a piece of plasticine with toughness and plasticity with a volume to fill the bolt hole and 50mm higher than the end fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com