Machining center

A machining center and tool technology, applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve the problems of rising manufacturing costs, inability to prevent chips, chips and coolant from easily entering the tool warehouse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

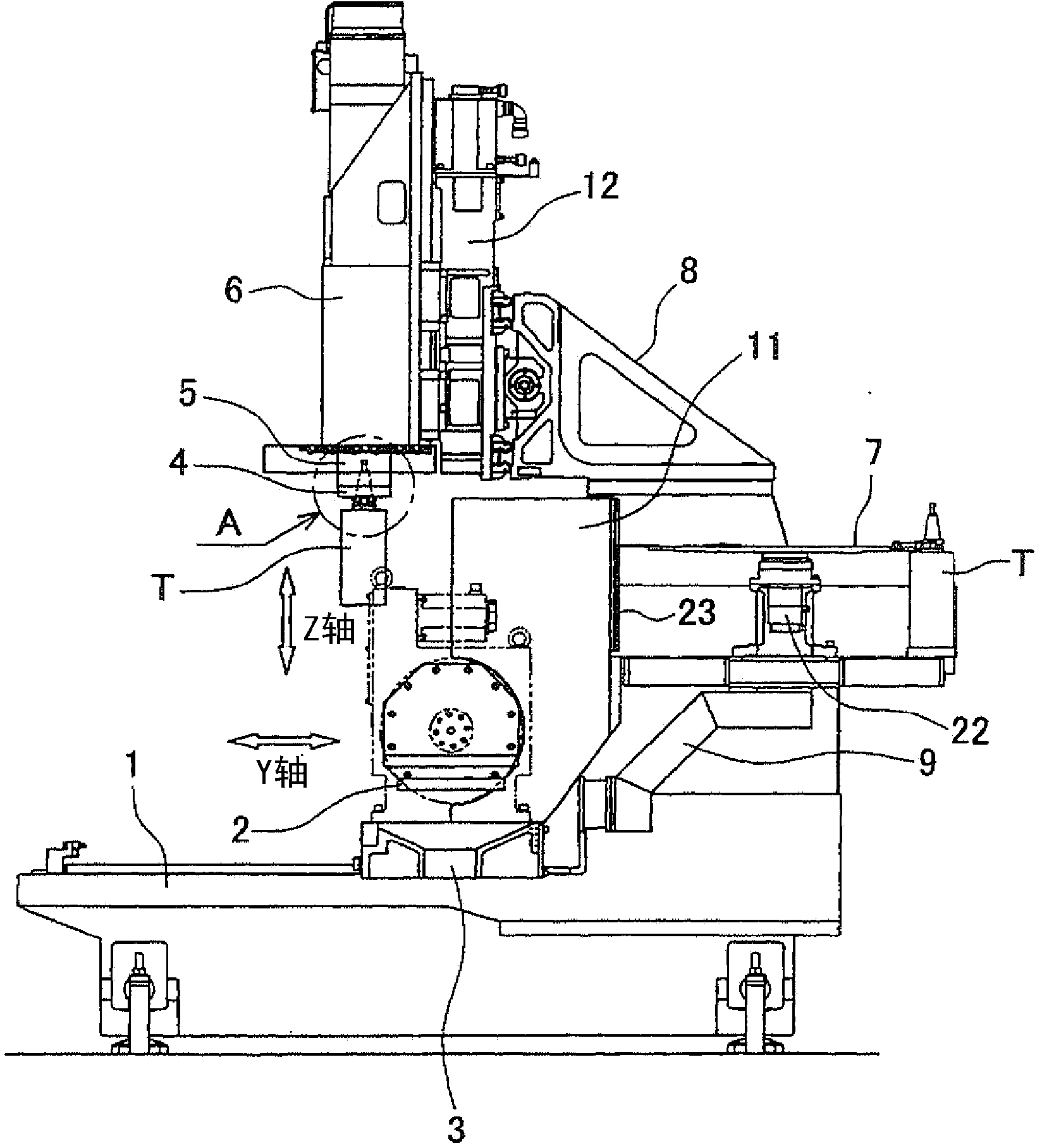

[0030] Specific embodiments of the present invention will be described below with reference to the drawings. figure 1 It shows an example of the machining center of this invention, and is a side view of the state at the time of machining. Reference numeral 1 is a base constituting the base of the machining center, reference numeral 2 is a table on which a workpiece is placed on a slide base 3 described later, reference numeral 3 is a slide base for moving the table 2 in the front-rear direction, Reference numeral 4 is a spindle arranged above the table 2 to rotate the tool T attached thereto, reference numeral 5 is a spindle head supporting the spindle 4, reference numeral 6 is a spindle head lifting body for moving the spindle head 5 up and down, and reference numeral 7 is a spindle head for An armless automatic tool changer (hereinafter referred to simply as an ATC device) that accommodates a plurality of tools T and replaces the tools T mounted on the spindle 4. Reference n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com