Crushing knife of crusher

A technology of crushing knives and crushers, applied in grain processing, etc., can solve problems such as low work efficiency, not easy to break, and unsatisfactory effects, and achieve the effect of good crushing effect, simple structure, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

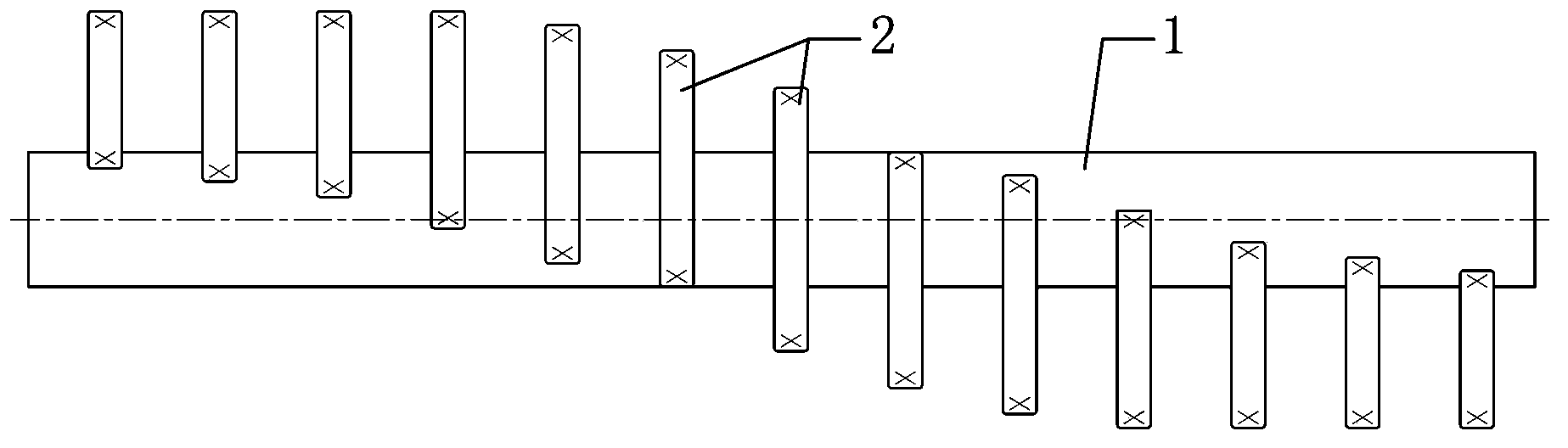

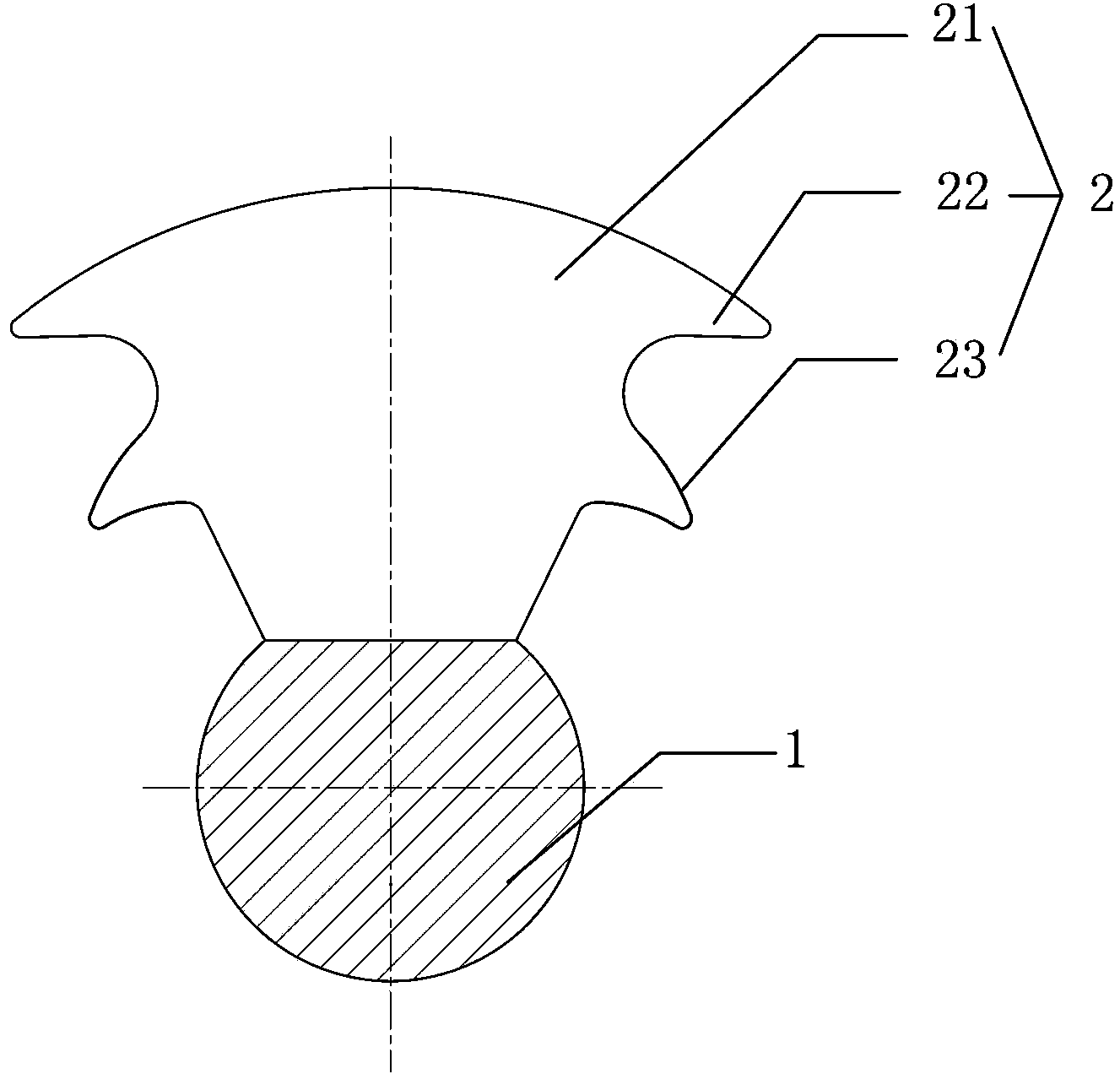

[0014] Such as figure 1 and 2 As shown, the crushing knife of the crusher includes a rotating shaft 1 and several blades 2 arranged on the rotating shaft. The lower cutter body 23 located between the rotating shaft 1 and the upper cutter body 22 on the side of the body 21 has a smooth transition at the connection between the upper cutter body 22 and the body 21 , and a smooth transition at the connection between the lower cutter body 23 and the body 21 . The body 21 is welded on the rotating shaft 1 . The body 21 gradually narrows from an end away from the rotating shaft 1 to an end connected to the rotating shaft 1 . The above-mentioned several blades are helically distributed on the rotating shaft 1 along the axial direction of the rotating shaft 1 , preferably helically evenly distributed on the rotating shaft 1 . The number of blades is preferably 13. When several blades are helically distributed on the rotating shaft 1, among two adjacent blades, the center of the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com