Ternary tobacco fiber paper filter rod made from composite aroma-enhancing plants and preparation method of filter rod

A technology of tobacco fiber and aroma plants, which is applied in the fields of tobacco, e-liquid filter, food science, etc., can solve the problem of not finding paper filter material, etc., and achieve excellent coke reduction and harm reduction functions, high adsorption and relative absorption. , the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

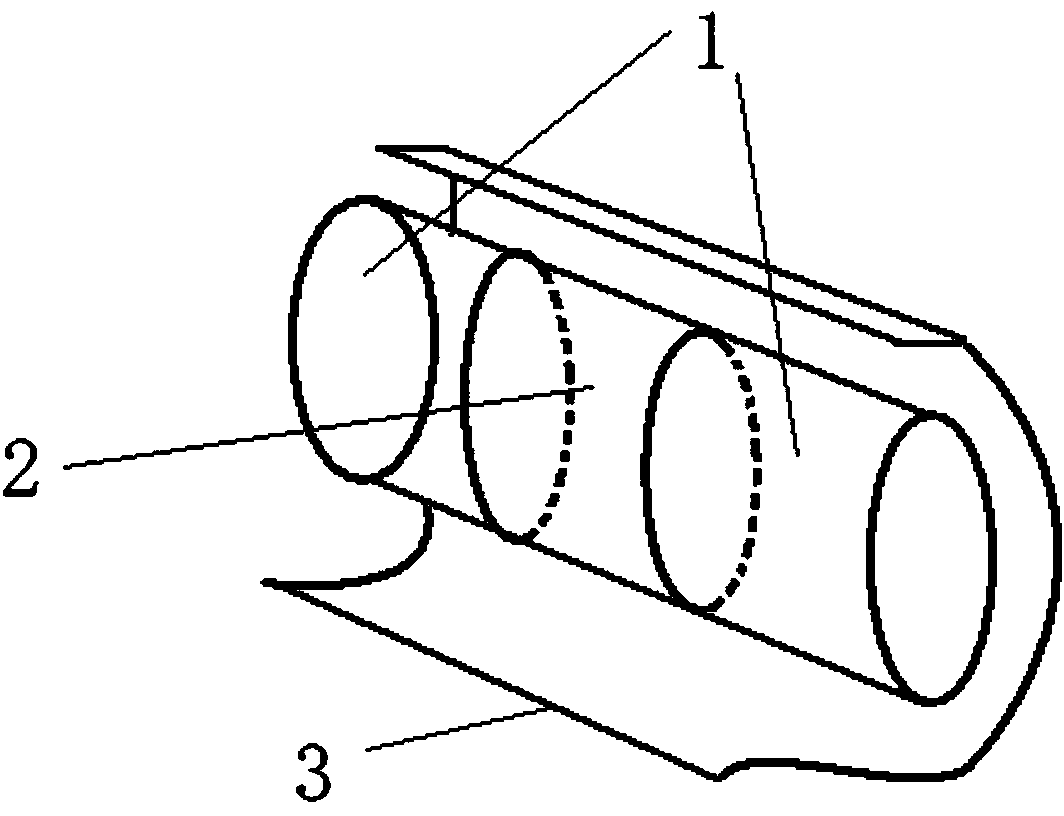

Image

Examples

Embodiment 1

[0047] S1 prepares tobacco fiber filter element with tobacco leaves, tobacco stems and licorice

[0048] (1) Extracting tobacco leaves and tobacco stems

[0049] S11. extracting the tobacco raw material to obtain an extract of the tobacco raw material and a solid slag of the tobacco raw material;

[0050] In this example, tobacco stems and water were extracted at a mass ratio of 1:7 at a temperature of 60°C and an extraction time of 100 minutes, and the extraction was repeated three times. Tobacco stem extract and tobacco stem solid slag obtained after treatment.

[0051] Tobacco leaves and water were extracted at a mass ratio of 1:10, the extraction temperature was 80°C, and the extraction time was 60 minutes, and the extraction was repeated three times. Tobacco leaf extract and tobacco leaf solid slag obtained after treatment.

[0052] S12. Refining the solid slag of tobacco raw materials to obtain tobacco fiber pulp; commercially available lignocellulosic pulp. The r...

Embodiment 2

[0060] S1. Preparation of grooved tobacco fiber filter rods from tobacco powder, tobacco fragments and tobacco stalks

[0061] S11. extracting the raw material to obtain the extract of the raw material and the solid slag of the raw material;

[0062] In this example, tobacco stems and water were extracted at a mass ratio of 1:7 at a temperature of 60°C and an extraction time of 100 minutes, and the extraction was repeated three times. Tobacco stem extract and tobacco stem solid slag obtained after treatment.

[0063] Tobacco leaves and water were extracted at a mass ratio of 1:10, the extraction temperature was 80°C, and the extraction time was 60 minutes, and the extraction was repeated three times. Tobacco leaf extract and tobacco leaf solid slag obtained after treatment.

[0064] According to the mass ratio of solid to liquid of 1:10, the smoke fragments and water were separated, the extraction temperature was 75°C, and the extraction time was 60 minutes. The smoke chip ...

Embodiment 3

[0072] S1. Preparation of grooved tobacco fiber filter rods from tobacco dust, tobacco fragments and tobacco stems

[0073] S11. extracting the raw material to obtain the extract of the raw material and the solid slag of the raw material;

[0074] In this example, tobacco stems and water were extracted at a mass ratio of 1:7 at a temperature of 60°C and an extraction time of 100 minutes, and the extraction was repeated three times. Tobacco stem extract and tobacco stem solid slag obtained after treatment.

[0075] Tobacco leaves and water were extracted at a mass ratio of 1:10, the extraction temperature was 80°C, and the extraction time was 60 minutes, and the extraction was repeated three times. Tobacco leaf extract and tobacco leaf solid slag obtained after treatment.

[0076] According to the mass ratio of solid to liquid of 1:10, the smoke fragments and water were separated, the extraction temperature was 75°C, and the extraction time was 60 minutes. The smoke chip ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com