Multiparticulate l-menthol formulations and related methods

A menthol and multiparticulate technology, applied in the field of high-purity L-multiparticulate preparations, can solve problems such as long residence time and unpredictable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] Example 1: Preparation of multiparticulate formulations

[0044] Experiment Details

[0045] Equipment used to manufacture the formulations described herein included: dish-on-dish balance, hand sieves (12, 14, 16, 18, weighing pan, 70 mesh screen), Rotap rotary sorting sieve, IKA mixer, KitchenAid Food Processor (Pre-Grind), Fitz Mill with 0.065'' Screen, Jet Mill, Key International High Shear Mixer, Glatt GPCC-3 Fluid Bed Dryer, Fluid Bed with 7'' Bottom Spray (wurster) Glatt GPCC-3 fluidized bed dryer, Karl Fischer moisture analyzer and spheronizer.

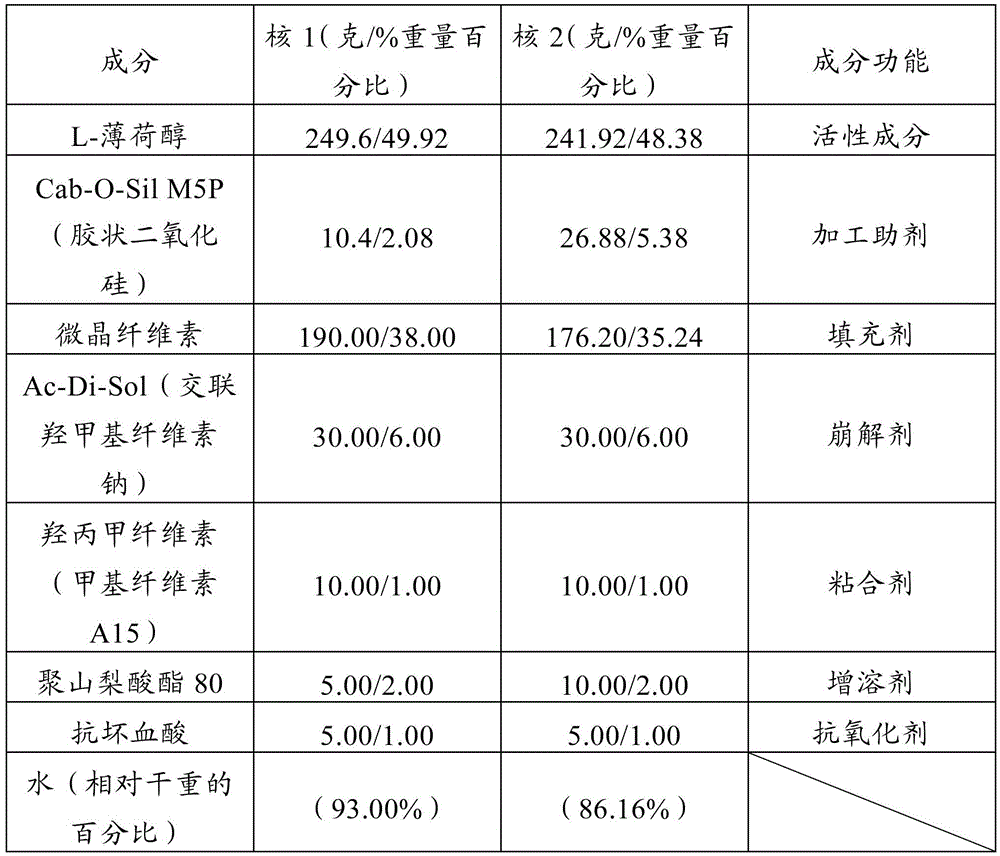

[0046] Preparation of Nucleus 1

[0047]As shown in Table 1, Core 1 was prepared as described above using the following settings. Wet granulation settings were: paddle speed 300 rpm, chopper speed 3450 rpm, wet granulation time 80 seconds to 90 seconds, maximum paddle power 5.5 amps to 6.2 amps. The extrusion settings were: paddle speed 25 rpm, feeder speed 30 rpm, screen diameter 1.2 mm. The extrudate was loaded to...

example 2

[0056] Example 2: Assays on prepared multiparticulate formulations

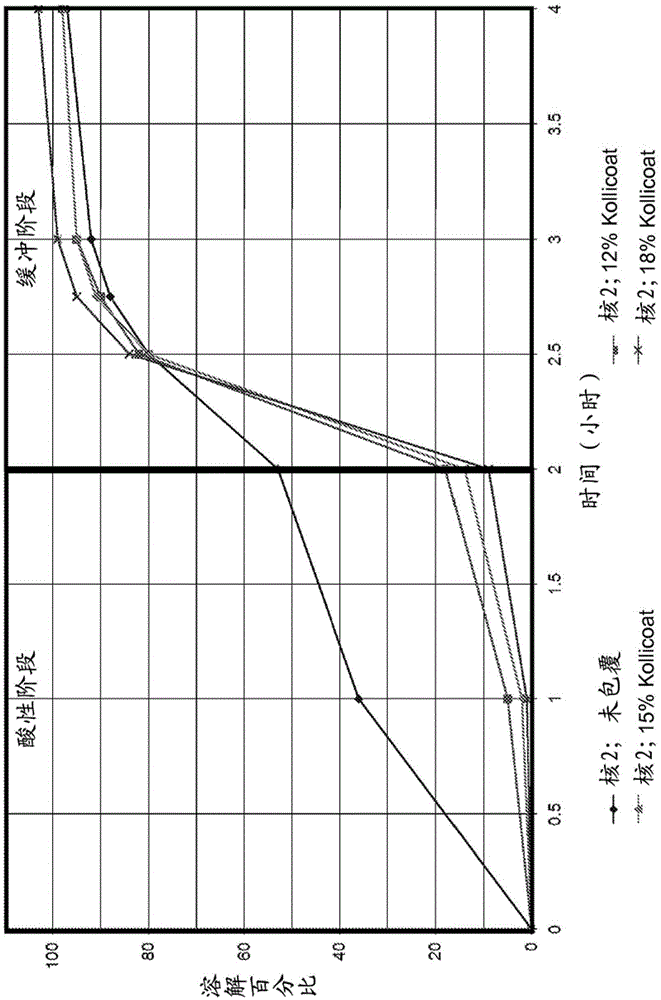

[0057] Prepared multiparticulate dosage forms were assayed to determine whether they met or approached the desired USP711 enteric specification. To meet the USP711 specification for enteric coating, less than 10% of the active ingredient should be released within 2 hours in 0.1N HCl solution (“acid phase”). Subsequently, not less than 85% of the active ingredient should be released within 45 minutes in a buffer solution with a pH value of 6.8 (“buffer phase”).

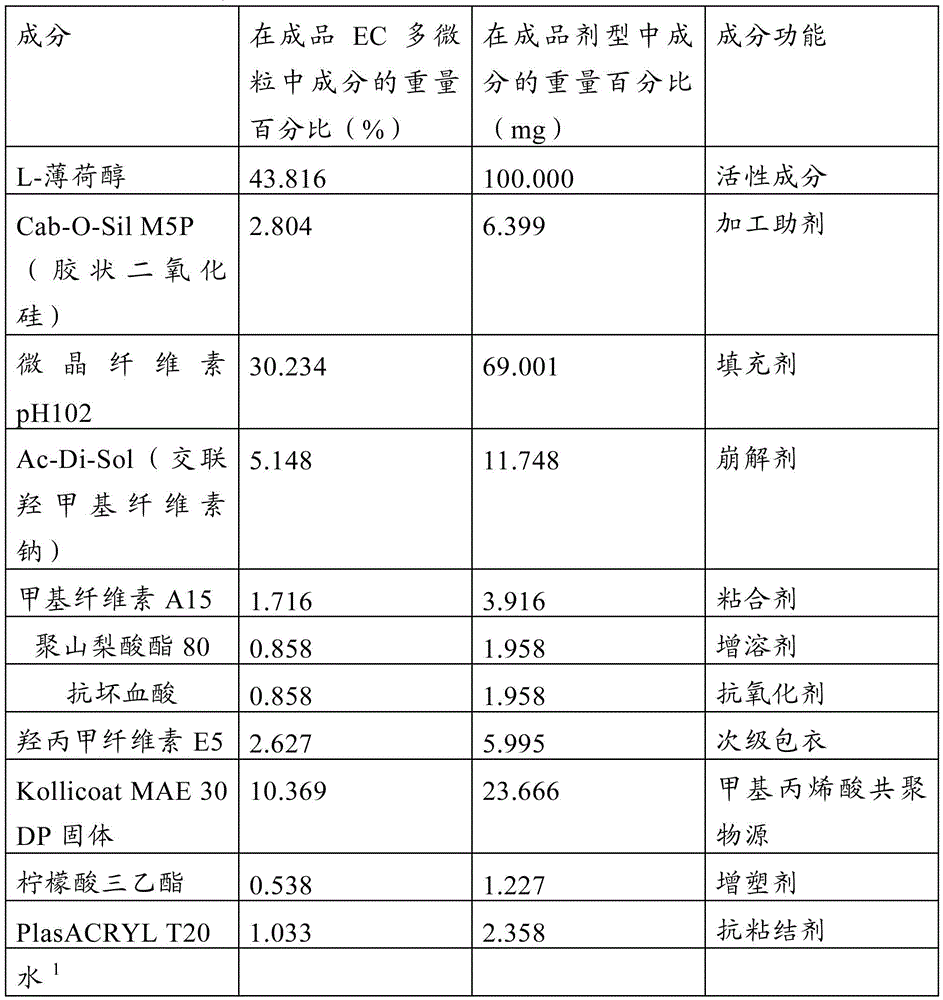

[0058] The data in Tables 5 and 6 indicate that both acrylic resin and Kollicoat coatings can be successfully used with crystalline L-menthol to form enteric-coated L-menthol multiparticulate formulations that meet or approach USP711 enteric specifications. In Tables 5 and 6, the batch identification indicates the core used, the coating on the core and the formulation number for the specific formulation. A secondary coating of 3% by weight hypromell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com