Metal oxide composite high flat cellulose powder and cosmetics containing same

A technology of cellulose powder and oxide, which is used in medical preparations, cosmetics, cosmetics and other directions containing active ingredients, can solve the problems of difference in use feeling, spreadability and completion, and achieve excellent continuous effect, excellent color rendering, excellent Effect of smooth usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Manufacture of lauroyl lysine-treated fine-grained titanium dioxide composite high-flat cellulose powder (1):

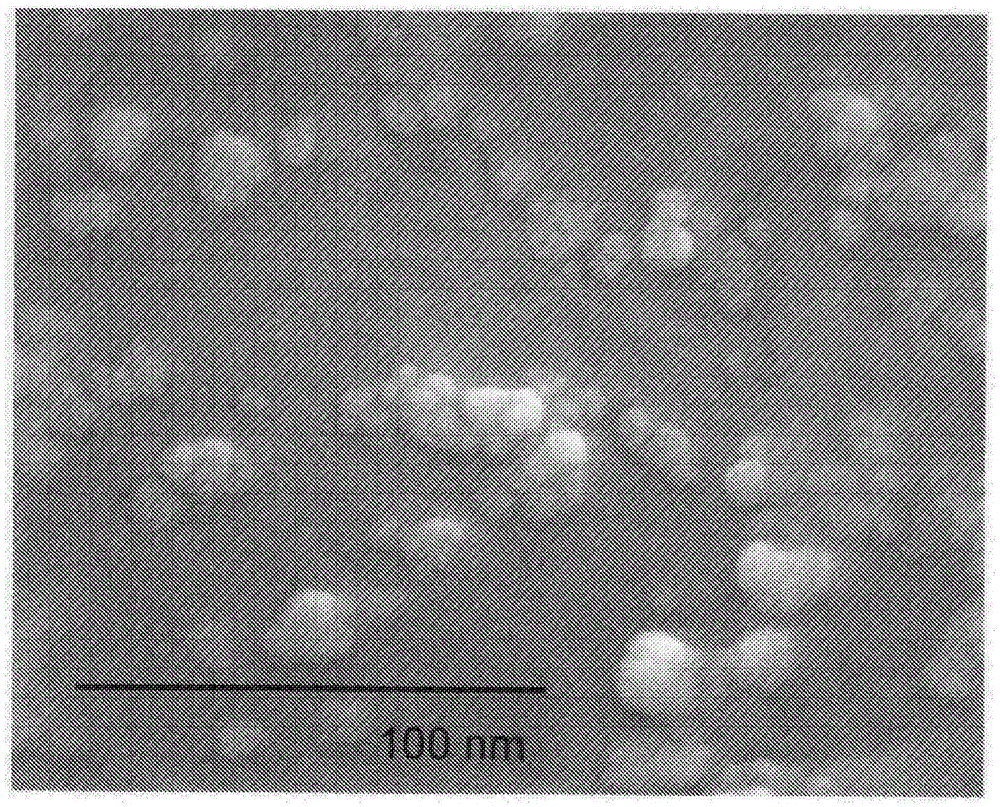

[0068] (1) A cellulose powder derived from refined wood pulp (Nippon Paper Chemicals: W-400G) was used as a raw material. First, the adsorbed moisture was sufficiently removed to 0.1% or less by drying under reduced pressure at 40°C, and the obtained cellulose powder (55.3 g) was put into a sealable alumina grinding container (volume 500 mL) together with alumina grinding balls. Further, 0.7 g of lauroyl lysine (manufactured by Amihope LL Ajinomoto Co., Ltd.) and 14 g of microparticle titanium dioxide (manufactured by Ishihara Sangyo Co., Ltd. TTO-S-4) (particle diameter minor axis: 10 nm to 20 nm, major axis: 50 nm to 100 nm) were added . Thereafter, it was pulverized using a planetary ball mill (Sansho Industry Co., Ltd.) at a rotation speed of 200 rpm (pulverization energy of about 10G (acceleration of gravity)) for 40 minutes to obtain lauroyl lysine-trea...

Embodiment 2

[0073] Manufacture of lauroyl lysine-treated fine-grained titanium dioxide composite high-flat cellulose powder (2):

[0074] A cellulose powder derived from refined wood pulp (Nippon Paper Chemicals: W-400G) was used as a raw material. First, the adsorbed moisture was sufficiently removed to 0.1% or less by drying under reduced pressure at 40°C, and the resulting cellulose powder (41.3 g) was put into a sealable alumina grinding container (volume 500 mL) together with alumina grinding balls. Further, 0.7 g of lauroyl lysine (manufactured by Amihope LL Ajinomoto Co., Ltd.) and 28 g of microparticle titanium dioxide (manufactured by Ishihara Sangyo Co., Ltd. TTO-S-4) were added. Thereafter, it was pulverized using a planetary ball mill (Sansho Industry Co., Ltd.) at a rotation speed of 200 rpm (pulverization energy of about 10G (acceleration of gravity)) for 40 minutes to obtain lauroyl lysine-treated microparticle titanium dioxide composite high flat cellulose powder (Product...

Embodiment 3

[0077] Manufacture of Hydrogenated Lecithin Treated Granular Titanium Dioxide Composite High Flat Cellulose Powder (3):

[0078] A cellulose powder derived from refined wood pulp (Nippon Paper Chemicals: W-400G) was used as a raw material. First, the adsorbed moisture was sufficiently removed to 0.1% or less by drying under reduced pressure at 40°C, and the obtained cellulose powder (55.3 g) was put into a sealable alumina grinding container (volume 500 mL) together with alumina grinding balls. Further, 0.7 g of hydrogenated lecithin (manufactured by Lecinol S-10 made by Nikko Chemicals) and 14 g of microparticle titanium dioxide (manufactured by Ishihara Sangyo Co., Ltd. TTO-S-4) were added. Thereafter, the planetary ball mill (Sansho Industry Co., Ltd.) was used to grind at a rotational speed of 200 rpm (about 10G (gravitational acceleration) of grinding energy) for 40 minutes to obtain a hydrogenated lecithin-treated microparticle titanium dioxide composite high flat cellul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com