A device for increasing the heat flux density at the boundary of the outer wall of a pressure vessel

A critical heat flux density, pressure vessel technology, used in cooling devices, reactors, greenhouse gas reduction, etc., can solve problems such as pressure vessel failure, threat to containment integrity, radioactive material leakage, etc., to enhance heat exchange capacity, improve Safety, the effect of increasing the critical heat flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

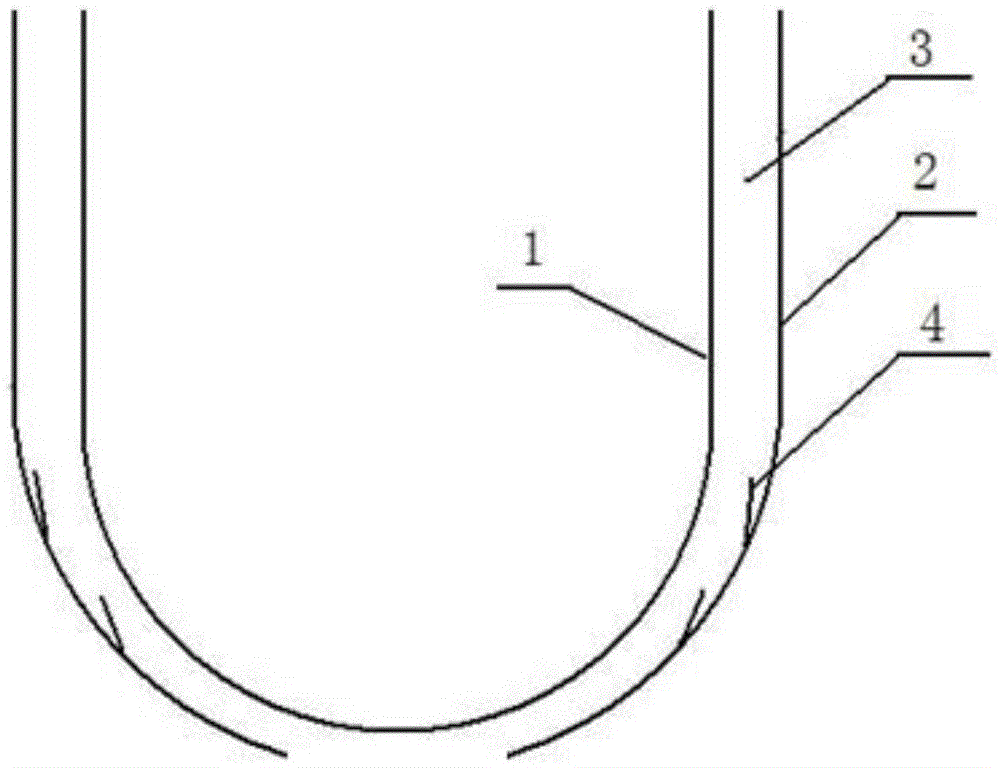

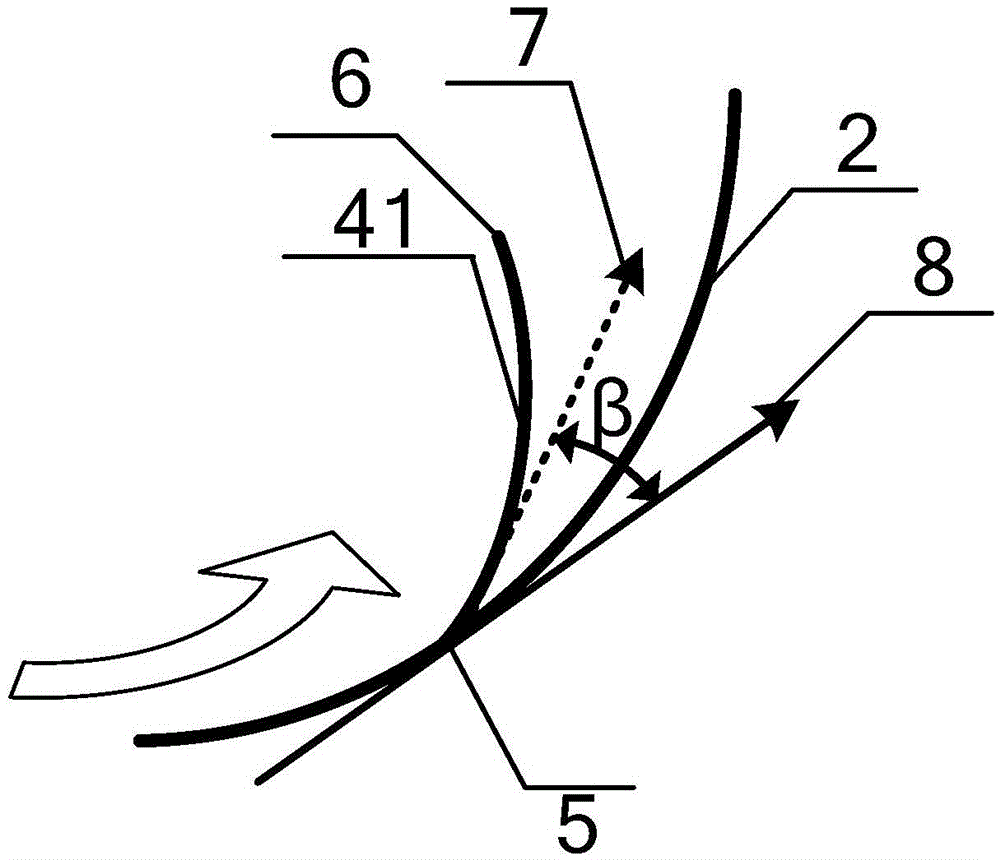

[0034] Such as figure 1 As shown, a device for improving the external critical heat flux density of the pressure vessel of a nuclear power plant includes a reactor pressure vessel 1 and an insulation layer 2 covering the outside of the reactor pressure vessel, and a flow channel is formed between the outer wall of the reactor pressure vessel 1 and the insulation layer 2 3. Among them, we define the interface between the reactor pressure vessel 1 and the flow channel 3 as the outer wall of the pressure vessel 1 .

[0035] Inside the flow channel 3 there is a protrusion 4 fixed on the inner wall surface of the insulation layer 2 . Similarly, the inner wall surface of the insulation layer 2 is defined as the interface between the insulation layer 2 and the runner 3 .

[0036] The reactor pressure vessel 1 includes components such as a cylinder body and a head. A longitudinal section view of a pressure vessel can be found in figure 1 , we define the wall of the cylinder part a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com