On-line measuring device for fly ash carbon content of flue

A fly ash carbon content and measurement device technology, applied in the direction of material excitation analysis, can solve the problems of large maintenance, large impact on measurement accuracy, unsatisfactory measurement stability and accuracy, and achieve the goal of ensuring high-precision measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

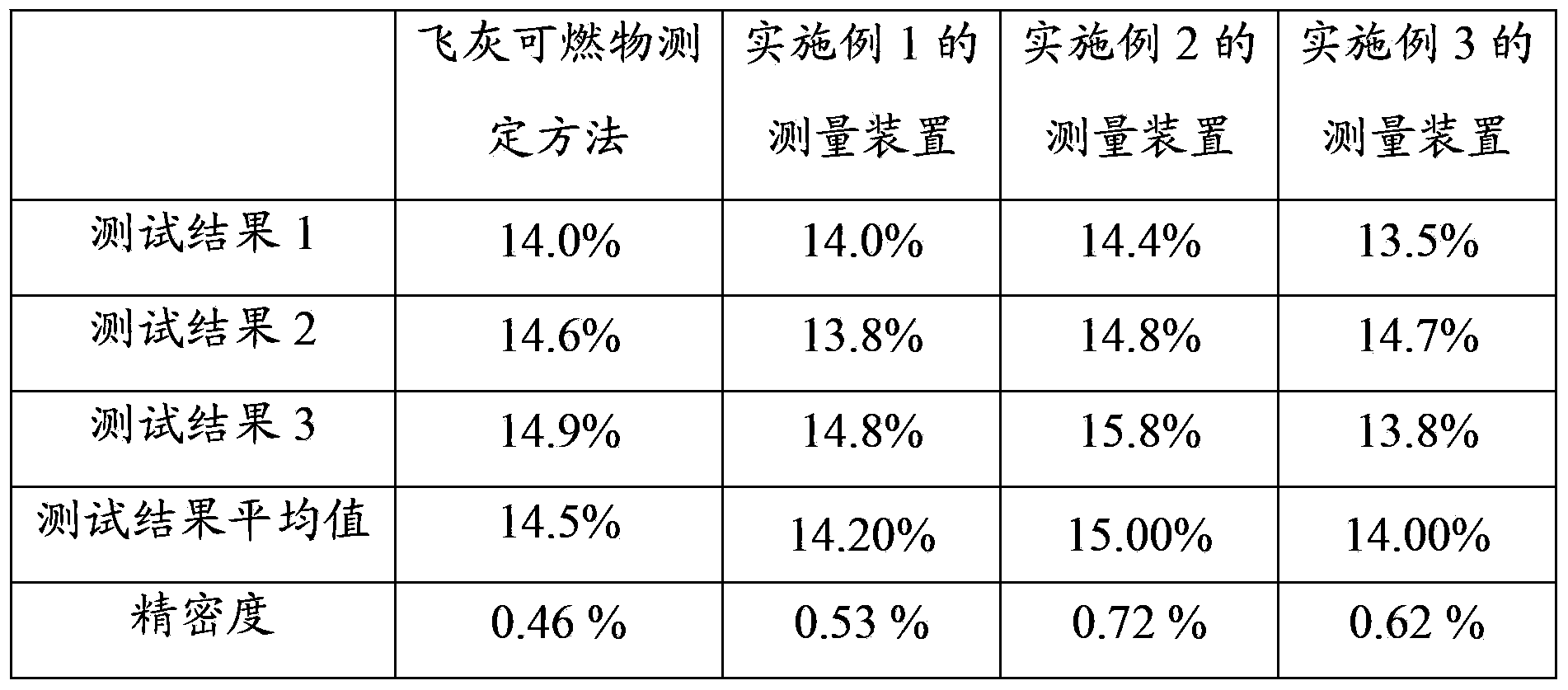

Embodiment 1

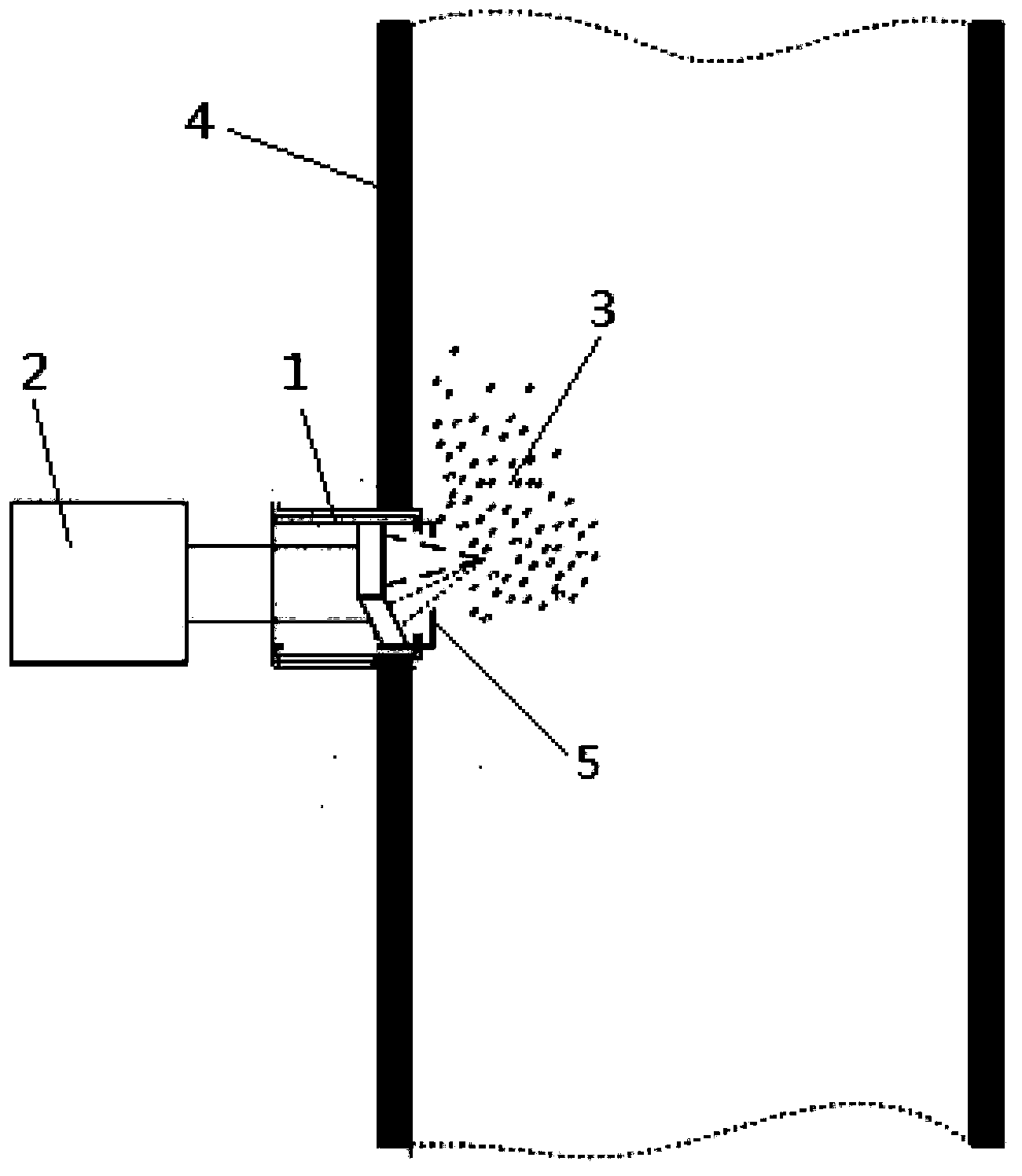

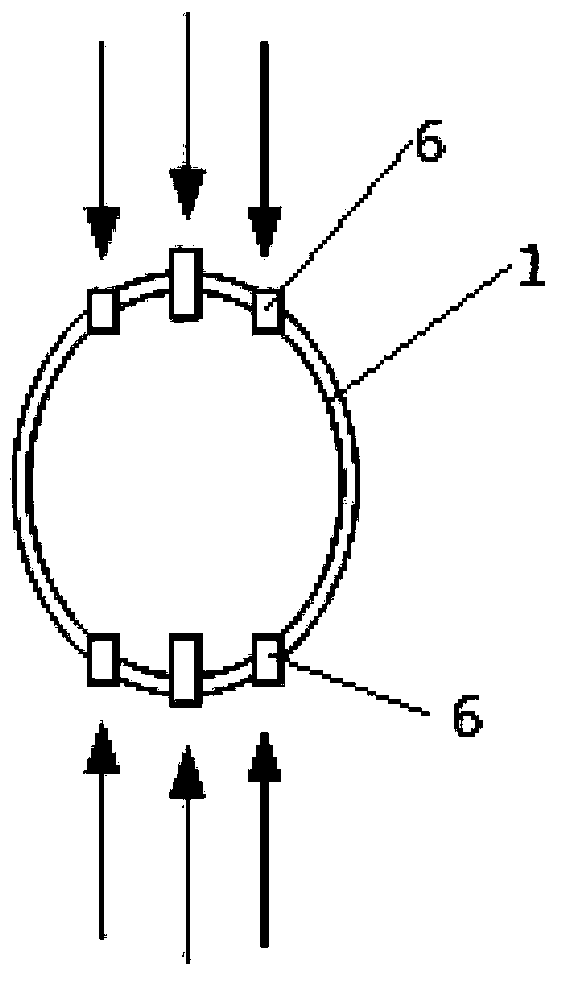

[0025] An online measurement device for carbon content in fly ash of flue, such as figure 1 As shown, it includes a measurement probe 1 and a measurement analysis unit 2. The measurement analysis unit includes a laser, a spectrometer, and a control device. The control device (ie, an industrial-grade micro industrial computer) is connected to the laser and the spectrometer; the measurement probe includes a housing , A laser focusing module and a spectral signal collecting module, the laser focusing module and the spectral signal collecting module are installed in the housing, the laser focusing module is connected to a laser, and the spectral signal collecting module is connected to a spectrometer; the housing of the measuring probe It is opened on the inner wall of the flue 4, and the edge of the opening of the shell is provided with a gas purging device, which blows out gas to form a gas curtain 5, and the focusing area of the laser focusing module and the spectral signal coll...

Embodiment 2

[0037] The on-line measuring device for carbon content of fly ash in the flue of this embodiment is basically the same as that of embodiment 1, except that:

[0038] The amount of gas blown by the gas purging device is 10 L / min.

[0039] There is an angle of 30° between the laser light generated by the laser focusing module and the signal collection optical path of the spectral signal collection module.

[0040] The gas purging device is only provided with a set of blowing ports, and since the gas purging direction of the gas purging device is parallel to the opening surface of the housing, the opening surface of the measuring probe housing is parallel to the flue axial direction. The air port is blowing from top to bottom.

Embodiment 3

[0042] The on-line measurement device for carbon content in fly ash of the flue in this embodiment is basically the same as that in embodiment 2, except that:

[0043] The amount of gas blown by the gas purging device is 10 L / min.

[0044] The laser light generated by the laser focusing module and the signal collection optical path of the spectral signal collection module form an angle of 60°.

[0045] The gas purging device is only provided with a set of blowing ports, and since the gas purging direction of the gas purging device is parallel to the opening surface of the housing, the opening surface of the measuring probe housing is parallel to the flue axial direction. The air port is blowing from bottom to top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com