A Method for Measuring Type II Crack Growth Rate of Composite Materials That Can Obtain S-N Curve of Crack Growth

A technology of crack growth rate and crack growth, which is used in the measurement of type II crack growth rate of composite materials and the field of composite material testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

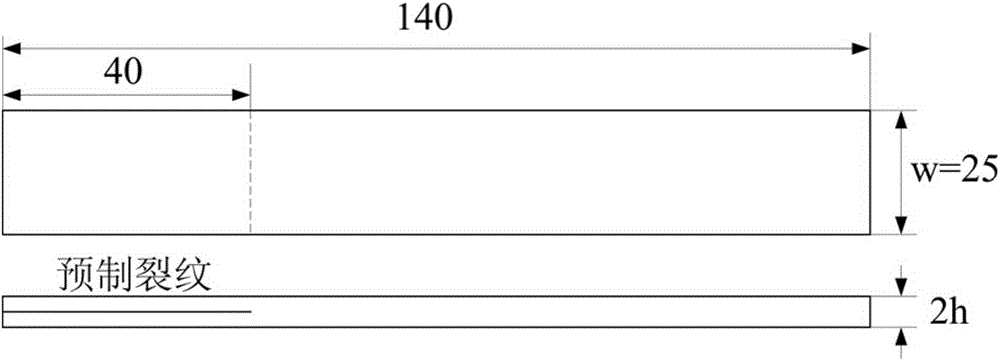

[0064] S-N curve and growth rate measurement method for mode II crack growth of glass fiber composites.

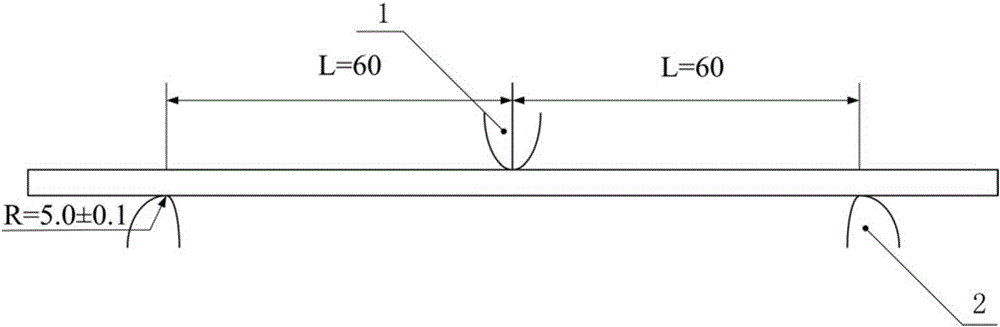

[0065] 32 samples were randomly selected and numbered. The geometric dimensions are as figure 1 Shown. Perform artificial type I pre-cracking of the sample. Firstly, draw a line at a distance of 45mm from the pre-cracked end of the sample on both sides; secondly, insert a wedge-shaped blade with a straight front edge into the pre-cracked surface along the width of the test piece. And push the blade forward horizontally to expand the crack tip by about 5mm. After the cracks are prefabricated, the PTFE film is drawn out. Load the sample according to the loading method described in step 2 of the "specific implementation method" of this patent application. The test groups and the stress levels of each group are given in Table 1. The observation of cracks during the test is carried out in accordance with Step 3 in the "Specific Implementation Method" of this patent application....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com