A Lubrication Mechanism for Cutting Knife of Cross-cutting Machine

A technology of lubricating mechanism and cross-cutting machine, which is applied in the direction of engine lubrication, mechanical equipment, engine components, etc., can solve the problems of cutter wear, reduced service life, cutter metal fatigue, etc., to reduce maintenance costs, ensure quality, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

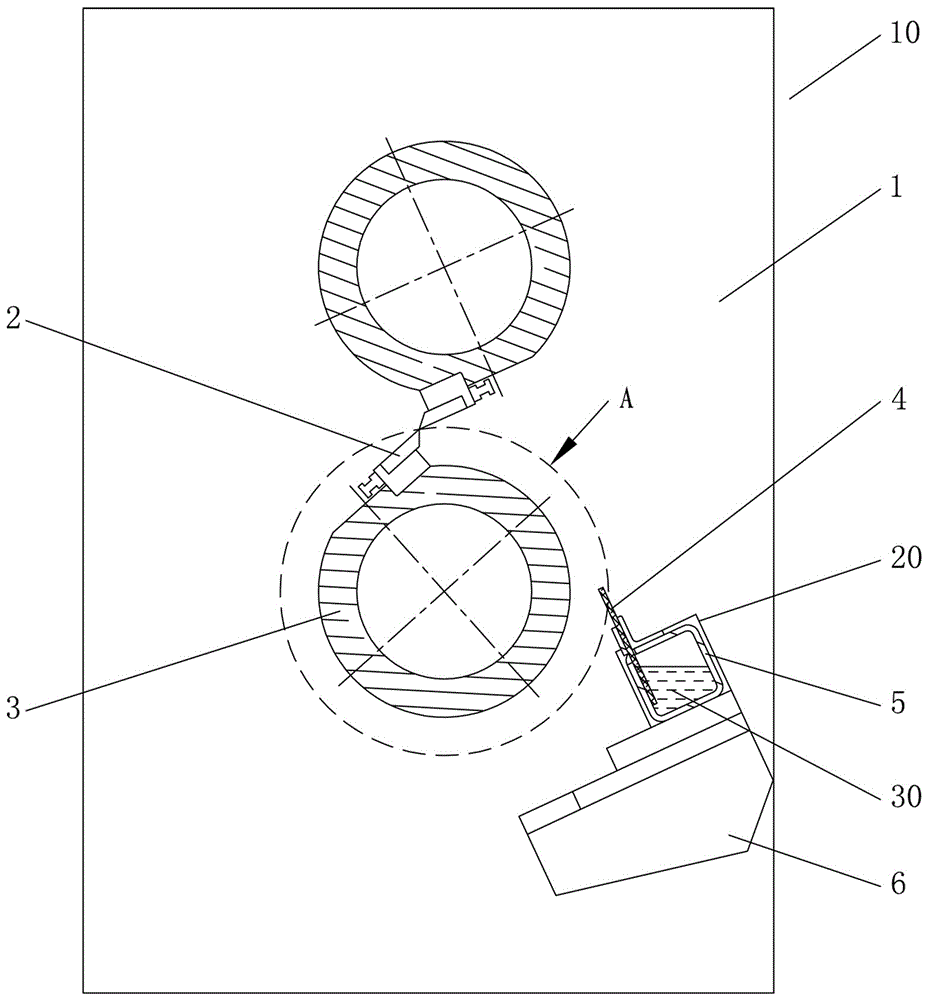

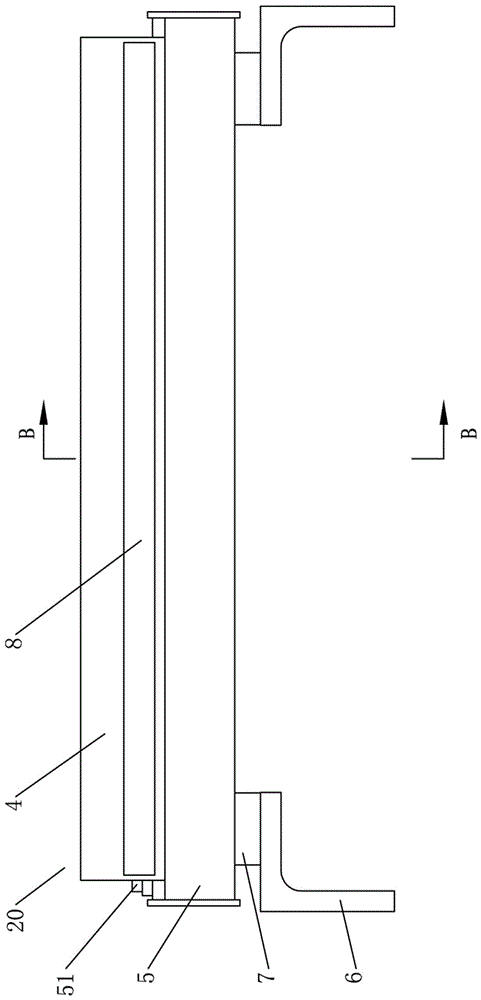

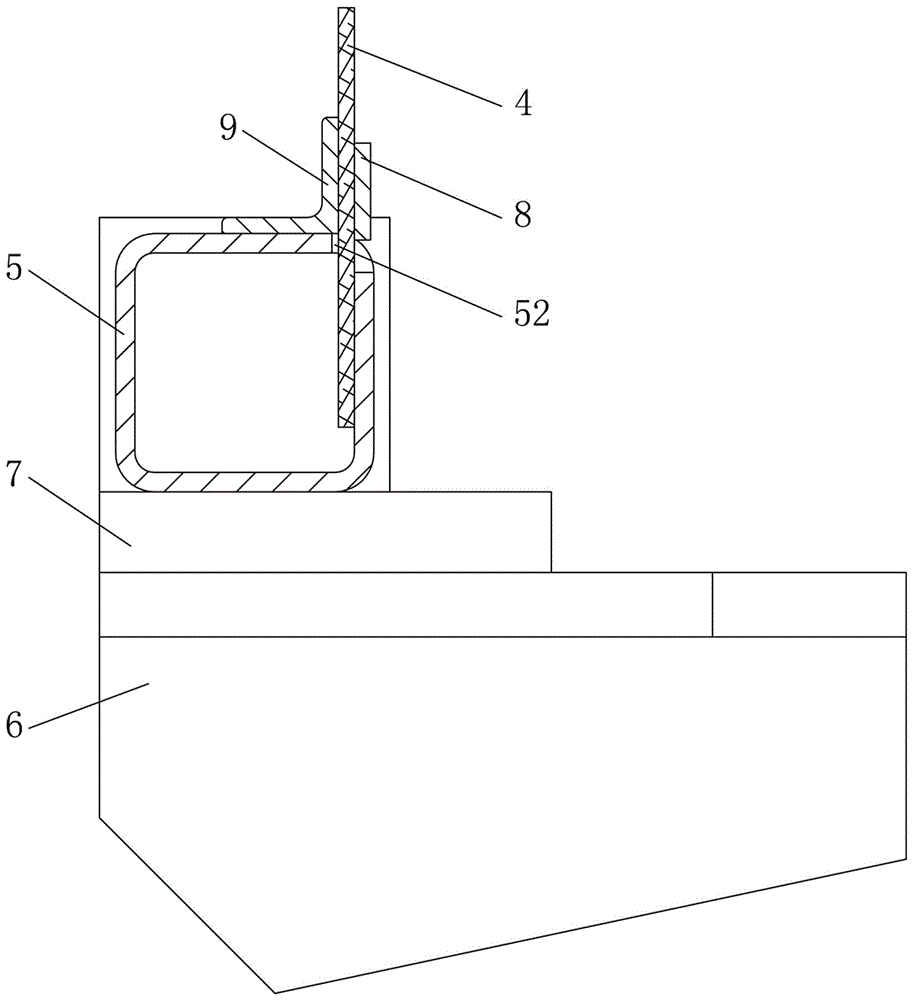

[0025] Embodiment one, see Figure 1 to Figure 3 As shown, a lubricating mechanism 20 of a cutter 2 of a crosscutting machine 10 , the lubricating mechanism 20 includes a liquid storage container 5 for holding a lubricating liquid 30 and a self-absorbing liquid brush for absorbing the lubricating liquid 30 . The self-absorbing brush is an oily felt 4, one end of the oily felt 4 is located in the liquid storage container 5, and the other end of the oily felt 4 is located outside the liquid storage container 5 for contacting with the cutter 2.

[0026] Lubricating oil 30 is filled in the liquid storage container 5, and the liquid storage container 5 is provided with a slot 52 corresponding to the sticky felt 4. The slot 52 extends along the length direction of the liquid storage container 5 and communicates with the inside and outside of the liquid storage container 5. , one end of the oil-sticking felt 4 is inserted into the liquid storage container 5 from the slot 52 and immer...

Embodiment 2

[0035] Embodiment two, the difference with embodiment one is: see Figure 4 , in order to facilitate the staff to know the stock of lubricating oil 30 in the liquid storage container 5 in time, a liquid level gauge 53 is provided on the surface of the liquid storage container 5, and the stock of lubricating oil 30 can be directly observed, so that when the stock of lubricating oil is relatively low Hours can be detected in time, and lubricating oil is added in the liquid storage container 5, thereby guaranteeing that the cutting knife 2 performs cutting work under the situation of effective lubrication and cooling, and guarantees the durability of the cutting knife.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com