Vibration-isolating and noise-reducing rubber support for buildings

A rubber bearing and vibration isolation technology, which is applied to building components, earthquake resistance, etc., can solve the problems of being unable to control the horizontal deformation direction and displacement of the upper structure, and cannot solve the problems of concrete structure cracking, poor vertical stiffness and vertical elasticity, etc. , to achieve the effects of reducing vibration and solid sound transmission, reducing self-weight, and meeting the requirements of vibration isolation and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

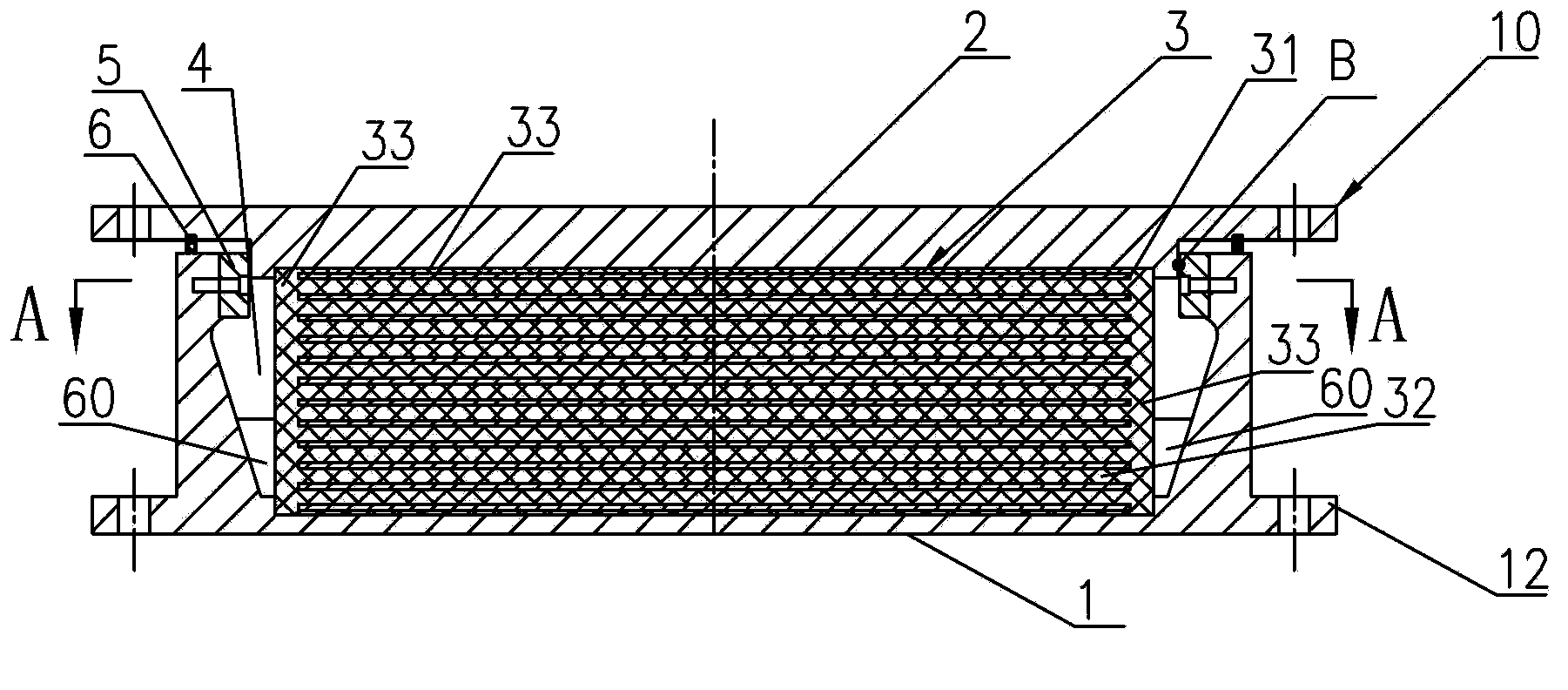

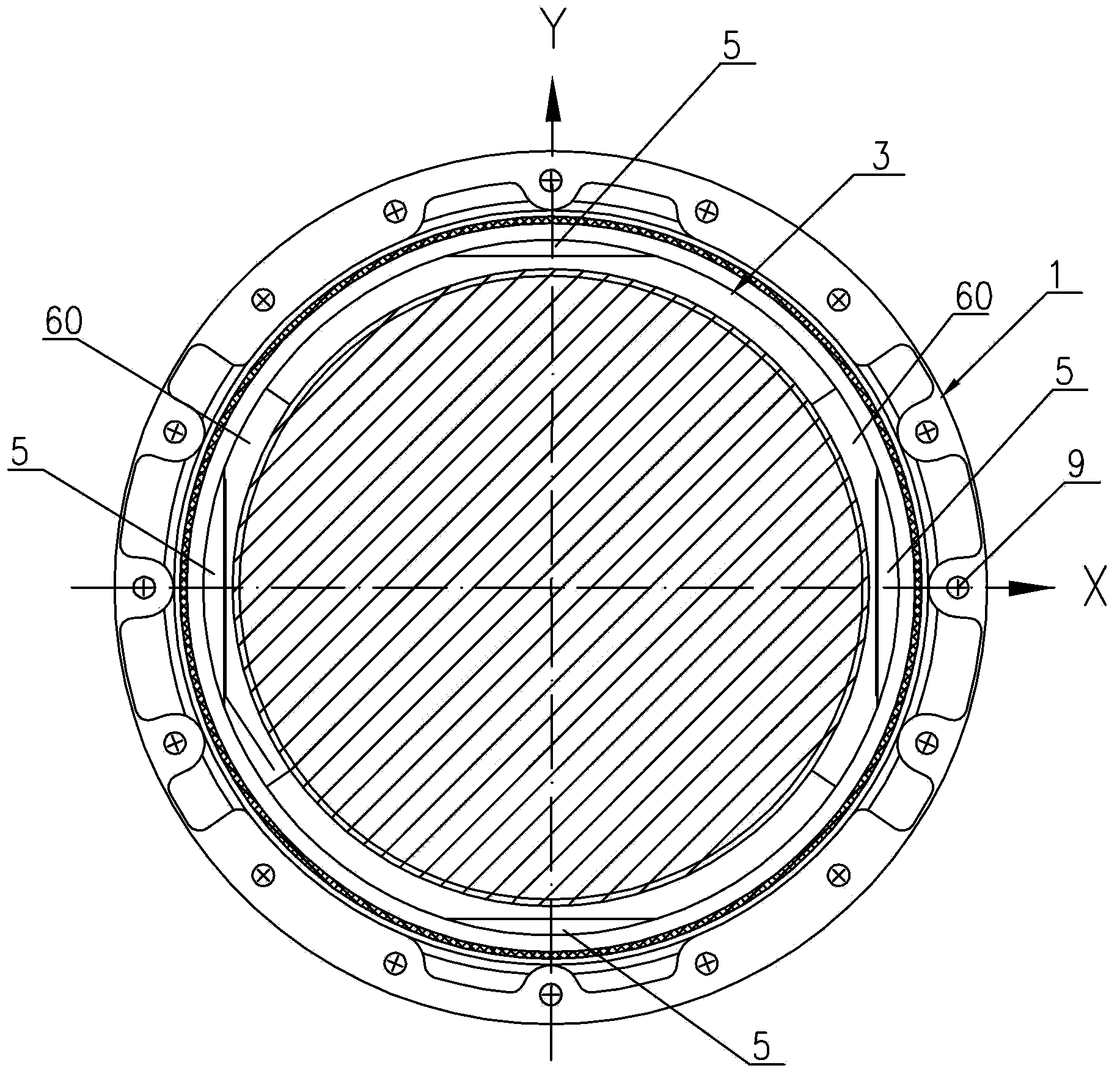

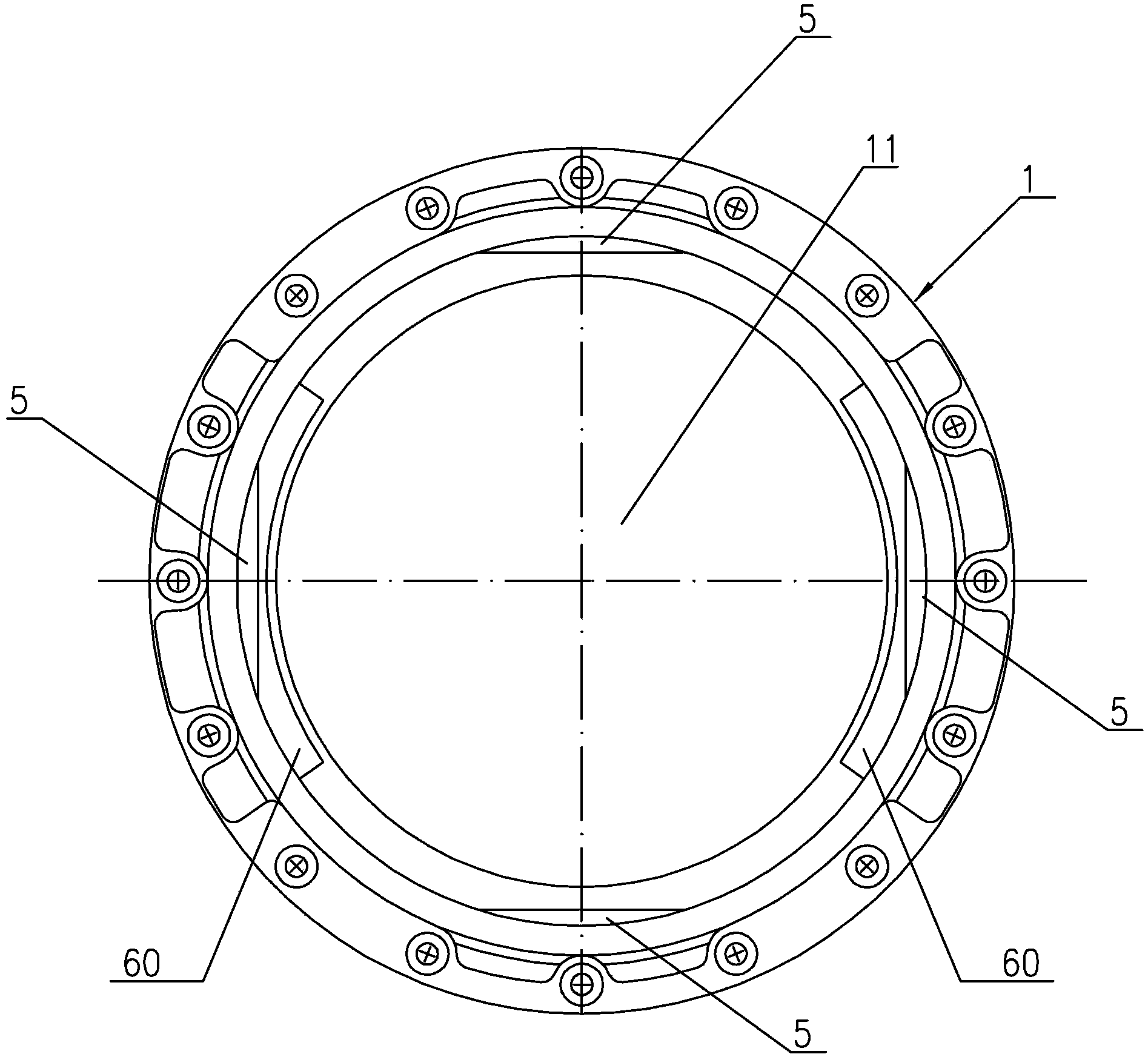

[0040] Such as Figure 1-9Shown is a building vibration isolation and noise reduction rubber bearing 10 of the present invention, including a base 1, an upper seat plate 2 and a cylindrical vibration isolation body 3, the base 1 is a block body with a concave installation cavity 11, and the vibration isolation The body 3 is arranged in the middle of the installation cavity 11, and the upper seat plate 2 is fastened to the upper end of the installation cavity 11 of the base 1 and pressed against the vibration isolator. In this embodiment, the vibration isolator 3 is composed of several layers of Q345B steel plates 31 and The chloroprene rubber sheets 32 are laminated and vulcanized at intervals to form a whole, and the ratio of the total thickness of the rubber sheets to the total thickness of the steel sheets is 2.5:1. In other embodiments, the number of layers of steel plates and neoprene sheets is calculated and determined according to actual conditions. The outer surface o...

Embodiment 2

[0050] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment is a support that meets the two-way displacement requirements, and the ratio of the total thickness of the rubber sheet to the total thickness of the steel sheet in the vibration isolator 3 is about 2.6:1. Two pairs of guide blocks 60 and limit blocks 5 are respectively arranged along the horizontal and vertical directions of the installation cavity. A gap B of 2mm is formed between the plane of the limit blocks and the edge of the installation groove. The guide blocks 60 are detachably installed on the base. The central angle formed by the two ends of the guide block 60 corresponding to the center of the installation cavity is 50 degrees. The limit blocks 5 are correspondingly located directly above the guide block 60, and the horizontal displacement of the vibration isolator in the lateral and vertical directions is relatively small.

[0051] According to actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com