Ice expansion resistant device for water conservancy project

A technology for water conservancy engineering and anti-ice swell, applied in water conservancy engineering, marine engineering, infrastructure engineering and other directions, can solve the problems of high labor cost, unsatisfactory use effect, large power consumption, etc., achieve good waterproof sealing performance, prevent Good freezing effect and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

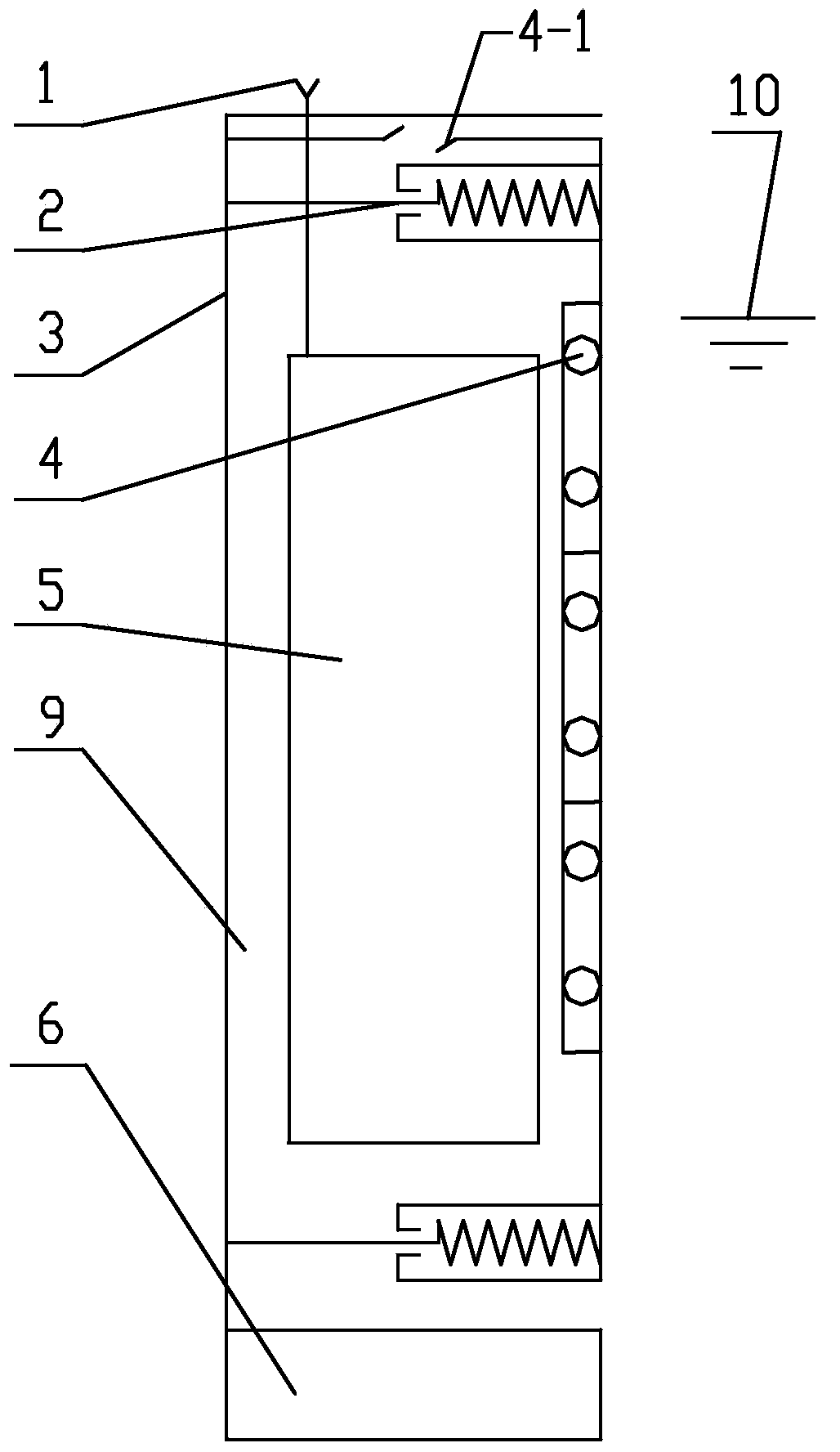

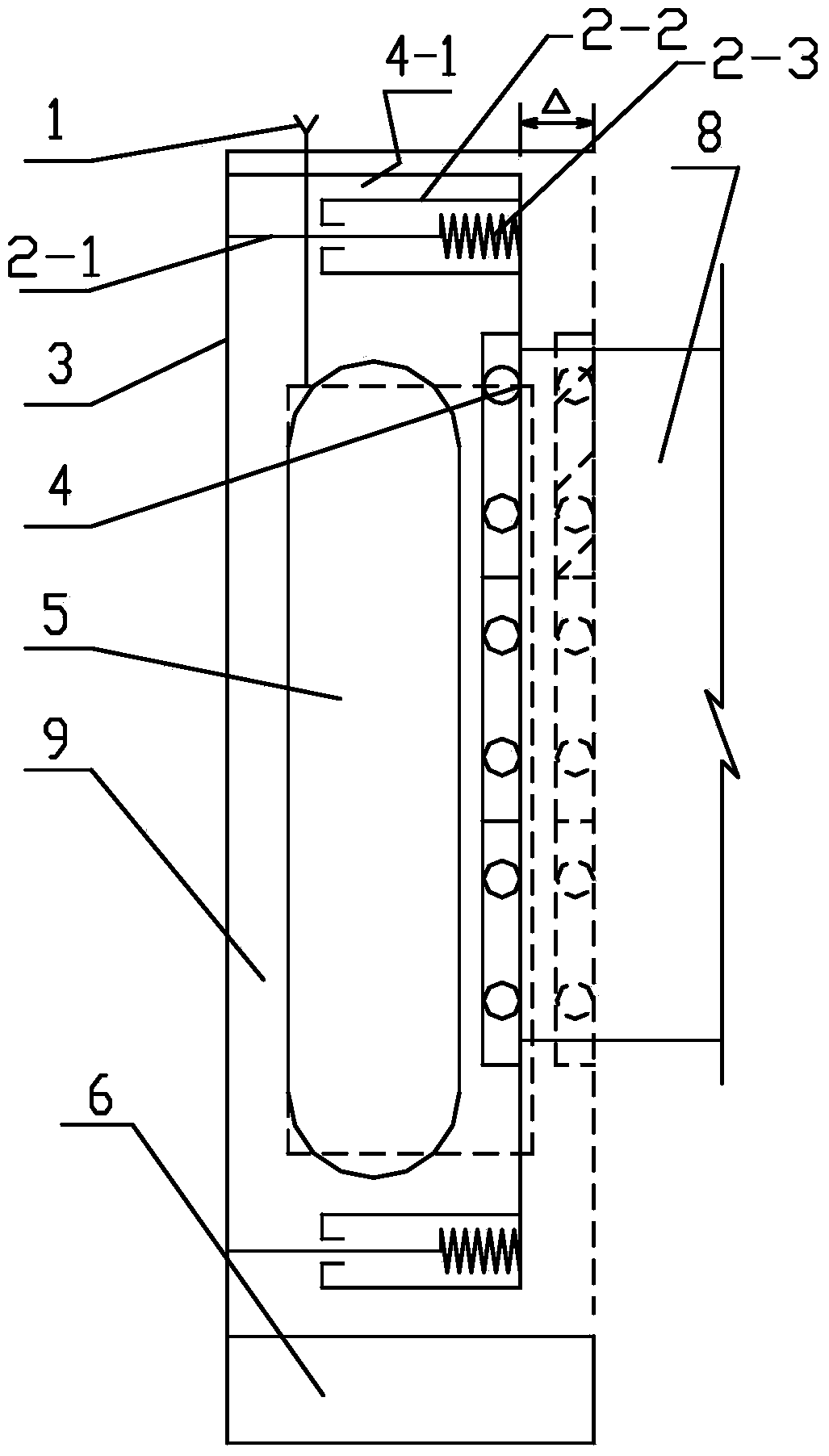

[0027] The present invention will be further described below in conjunction with the accompanying drawings. figure 1 , 2In , 3, the described anti-ice expansion device for water conservancy projects is characterized in that: the anti-ice expansion device includes a fixed frame 3, a movable hot plate 4 and a balance counterweight 6 arranged at the bottom of the fixed frame 3. Under the action of the balance counterweight 6, the fixed frame 3 can be placed vertically in the water. The selection of the balance counterweight 6 is determined according to the weight of the device, so that it just floats vertically in the water, and the damper 2 on its upper part is exposed on the water surface , the movable hot plate 4 is connected with the fixed frame 1 through the damper 2, and forms a sealed decompression chamber 9 with the fixed frame 3, the fixed frame 3 and the movable hot plate 4 form a sealed box, although the movable The hot plate 4 can move in parallel along the damper 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com