Steel tube arch bridge towerless buckling three-section type double-rib folding hoisting construction method

A technology of steel pipe arch bridges and construction methods, which can be applied to arch bridges, bridge forms, bridges, etc., and can solve the problem of complex stress on the tower buckle of the cable-stayed buckle-hanging suspension method, high water navigation capacity requirements, and structural instability during the rotation stage. problem, to achieve the effect of reducing cumbersome calculation and equipment installation, cable force adjustment and control flexibility, and large tensioning capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

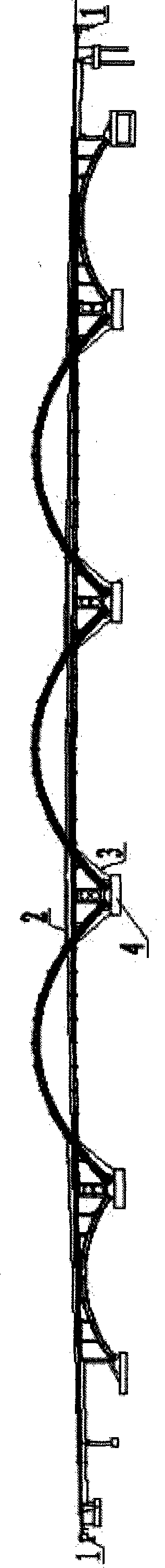

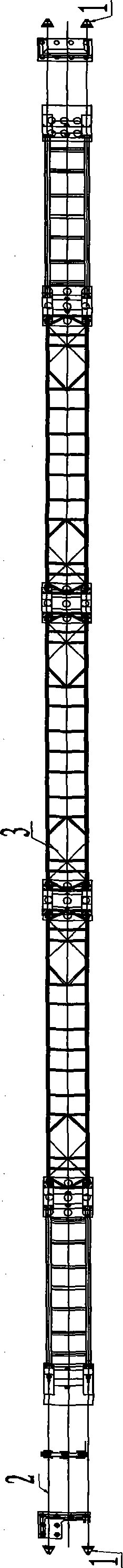

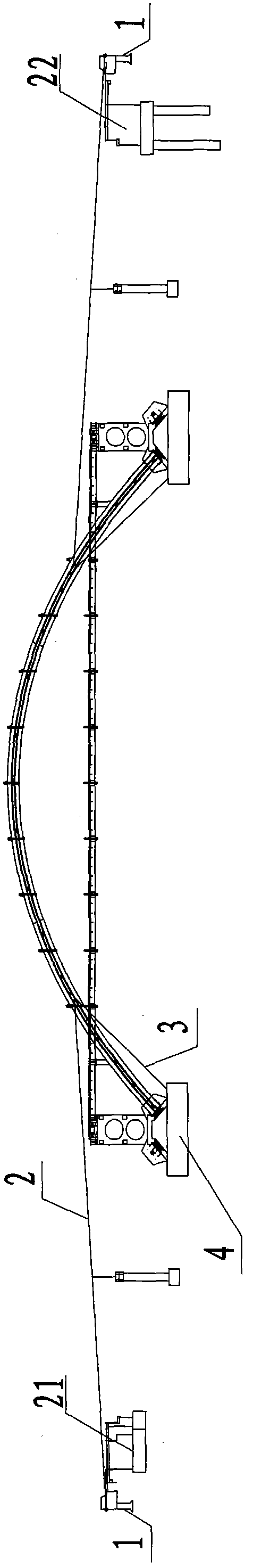

[0038] Take the 5# arch rib of Wenhui bridge reconstruction project in Liuzhou City, Guangxi Province as an example to specifically illustrate the construction method of the present invention below.

[0039] Wenhui Bridge is located in the downtown area of Liuzhou, and it is the main channel connecting the north and south of Liuzhou City. The reconstruction project of Wenhui Bridge is to build a new sister bridge downstream of the original bridge, which has the same appearance and the same structure as the original bridge. The superstructure includes 3-hole L=108m center-supported dumbbell-shaped concrete-filled steel pipe arches and two sides L=62m top-supported reinforced concrete box-rib arches, which are super-large bridges. Main arch rib and horizontal connection: mid-supporting concrete-filled steel tube arch axis coefficient: m=1.347, net span of 108 meters, net rise height of 27 meters, rise-span ratio of f / 1=1 / 4, dumbbell-shaped section height of 2.2 The diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com