Assembly type bamboo bridge

A prefabricated bamboo bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of self-heaviness, high maintenance cost, and low section stiffness, reduce the weakening of bearing capacity, improve lateral and longitudinal stiffness, The effect of ensuring stiffness and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

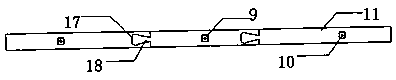

[0046] Such as Figure 1 to Figure 5 As shown, a prefabricated bamboo bridge comprises bamboo longitudinal girders 1, bamboo beams 2, bamboo panels 3, transverse prestressed bundles 4 and longitudinal prestressed bundles 16.

[0047] The top surface of the bamboo longitudinal beam 1 is provided with longitudinal beam protrusions 5 at intervals along the longitudinal direction of the bridge, the top surface of the bamboo beam 2 is provided with beam protrusions 6 at intervals along the transverse direction of the bridge, and the bamboo panel 3 includes prestressed tendons 7 and a plurality of horizontally stacked bridge deck sheets 8. The direction of its stacking arrangement is perpendicular to the direction of travel. The prestr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com