Modular counter-rotating twin-screw continuous plant fiber steam explosion modification device

A plant fiber and modular technology, applied in the direction of raw material separation, etc., to achieve the effects of less heat loss, large screw channel volume, and less steam loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0036] Example.

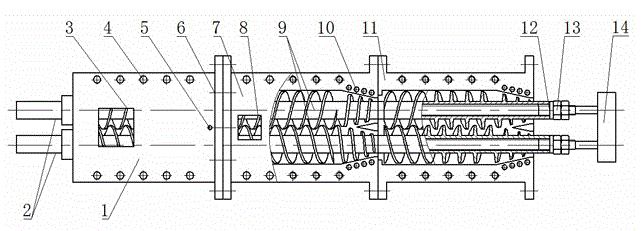

[0037] Such as figure 1 as shown, figure 1 It is a schematic diagram of the structure of the invented modular counter-rotating twin-screw continuous steam explosion modification device for plant fibers. Modular counter-rotating twin-screw continuous plant fiber steam explosion modification device, its core is a modular steam explosion unit composed of barrel and twin-screw, figure 1 It includes the first-stage modular steam explosion unit 1, the second-stage modular steam explosion unit 7, and the third-stage modular steam explosion unit 11, which are respectively fixed on the three-section frame, and the frame passes through the positioning device and the fastening mechanism. It is fixed and easy to disassemble and assemble. It can be converted into a single-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com