Method and device for increasing chroma of finished ethylene glycol product

A technology of ethylene glycol and crude ethylene glycol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as inability to remove oxalic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

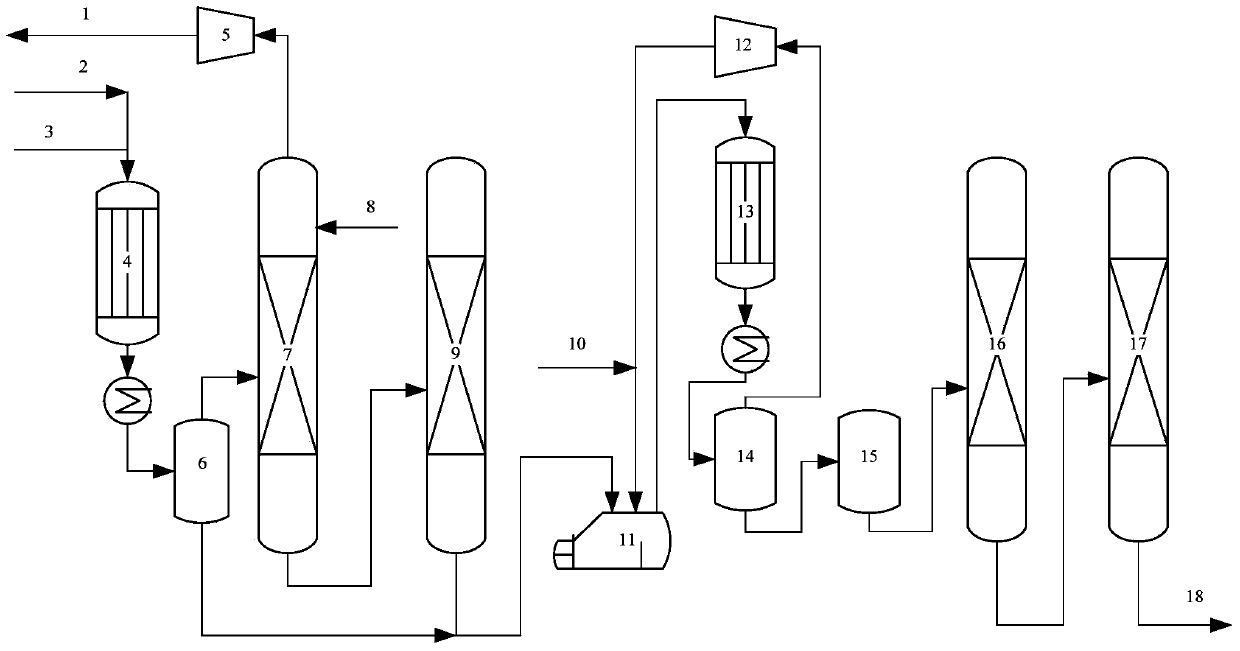

Image

Examples

Embodiment Construction

[0018] For further illustrating the present invention, specifically illustrate in conjunction with following examples:

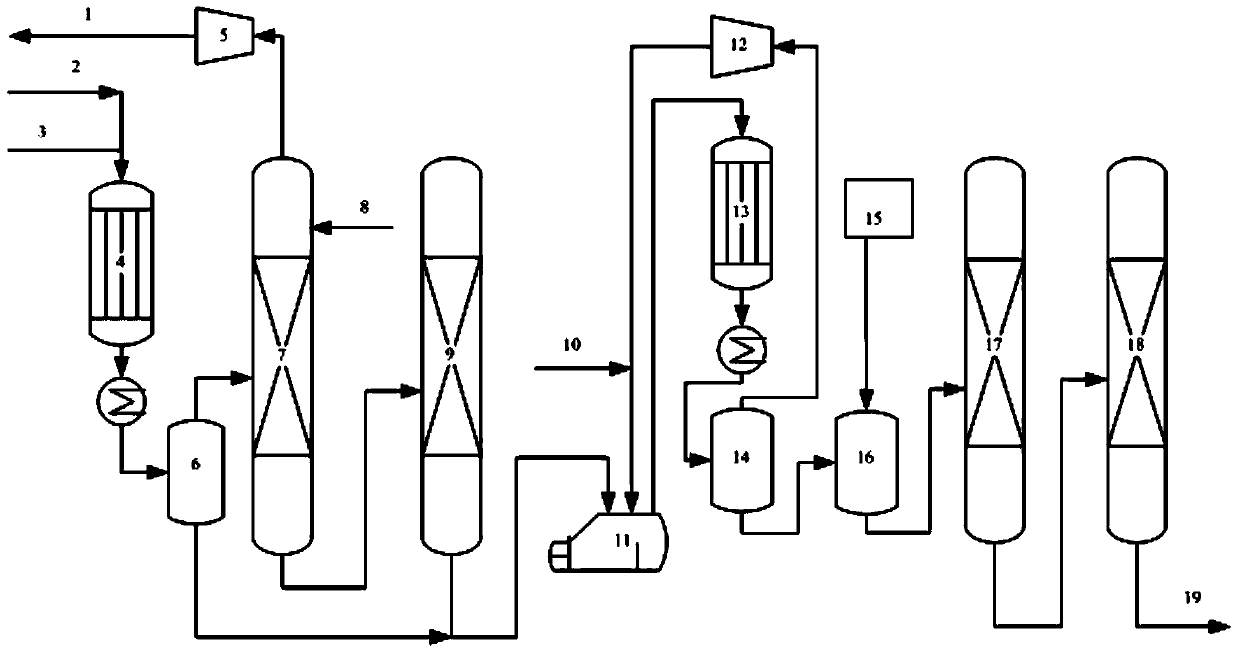

[0019] Such as figure 2 Shown, a kind of synthesis gas system ethylene glycol industrial device is in the synthesis gas system ethylene glycol industrial device, a lye storage tank 15 is added at the top of the crude ethylene glycol tank wherein, for the prepared The lye is added into the crude ethylene glycol tank; the lye is prepared from 90% methanol and 10% alkali.

[0020] The lye is used to neutralize the oxalic acid in the crude ethylene glycol, and can be selected according to the experience of the technicians. The alkali that can be used includes but is not limited to sodium hydroxide, potassium hydroxide, sodium bicarbonate, etc. After adding this to the crude ethylene glycol tank, it was stirred. After such treatment, it will be found that the color of the crude ethylene glycol changes from the original yellowish color to a clear and transparen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com