Method for preparing high temperature superconductive membrane by means of controlling fluorine-barium ratio of precursor

A high-temperature superconducting and precursor technology, applied in the field of high-temperature superconducting materials, can solve problems such as difficulty in continuous adjustment, and achieve the effects of favorable environment, fast preparation, and stress reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

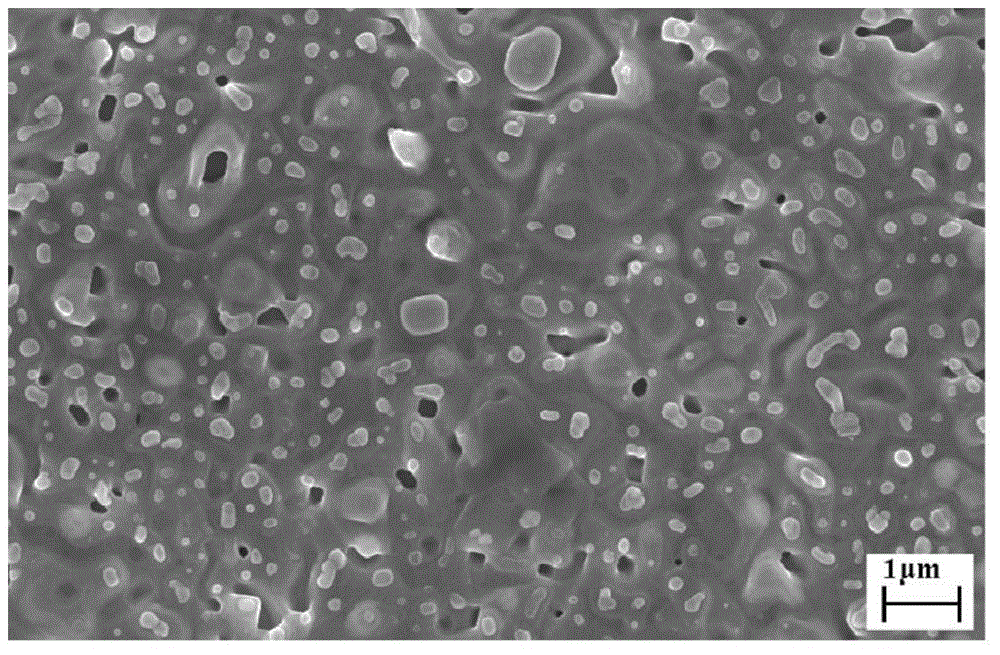

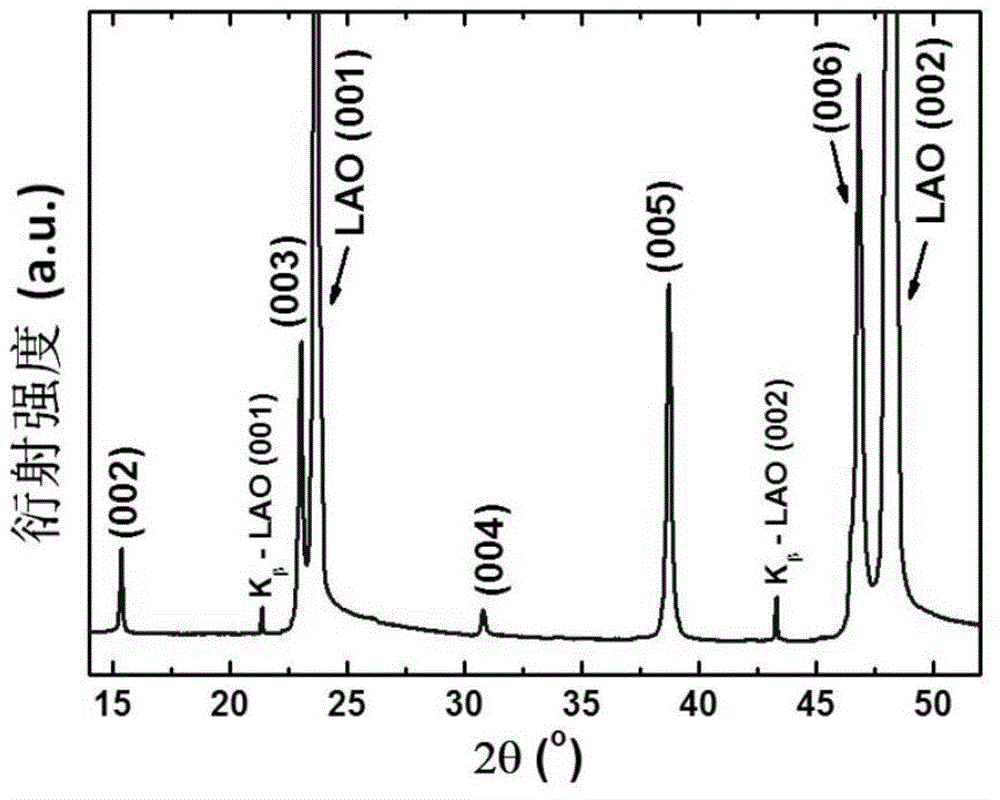

Image

Examples

Embodiment 1

[0043] A method for preparing a high-temperature superconducting film by controlling the fluorine-barium ratio of the precursor, the specific steps are as follows:

[0044] (1) Weigh the rare earth metal salt, trifluoroacetic acid (or trifluoroacetic anhydride), barium salt and copper salt in proportion and disperse them in the solvent, and obtain a uniform precursor after stirring; the rare earth metal salt, barium salt 1. The metal cation molar ratio of the copper salt is 1:(1+x):3, wherein, 0.5≤x≤1; the amount of trifluoroacetic acid (or trifluoroacetic anhydride) used must ensure that the fluorine and The molar ratio R of the two elements of barium is 2≤R≤4;

[0045] (2) Coating the precursor on the substrate to obtain a precursor film;

[0046](3) Put the precursor film obtained in step (2) into a heat treatment furnace, raise the temperature of the furnace to 300°C-650°C and keep it warm for 0-60 minutes;

[0047] (4) Raise the temperature of the furnace to 700°C to 82...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com