Landing gear for stepping moving type propeller strut of floating crane and landing steps of landing gear

A floating crane and step-moving technology, which is applied in cranes and other directions to achieve the effects of simple processing, novel structure and fast lifting and falling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

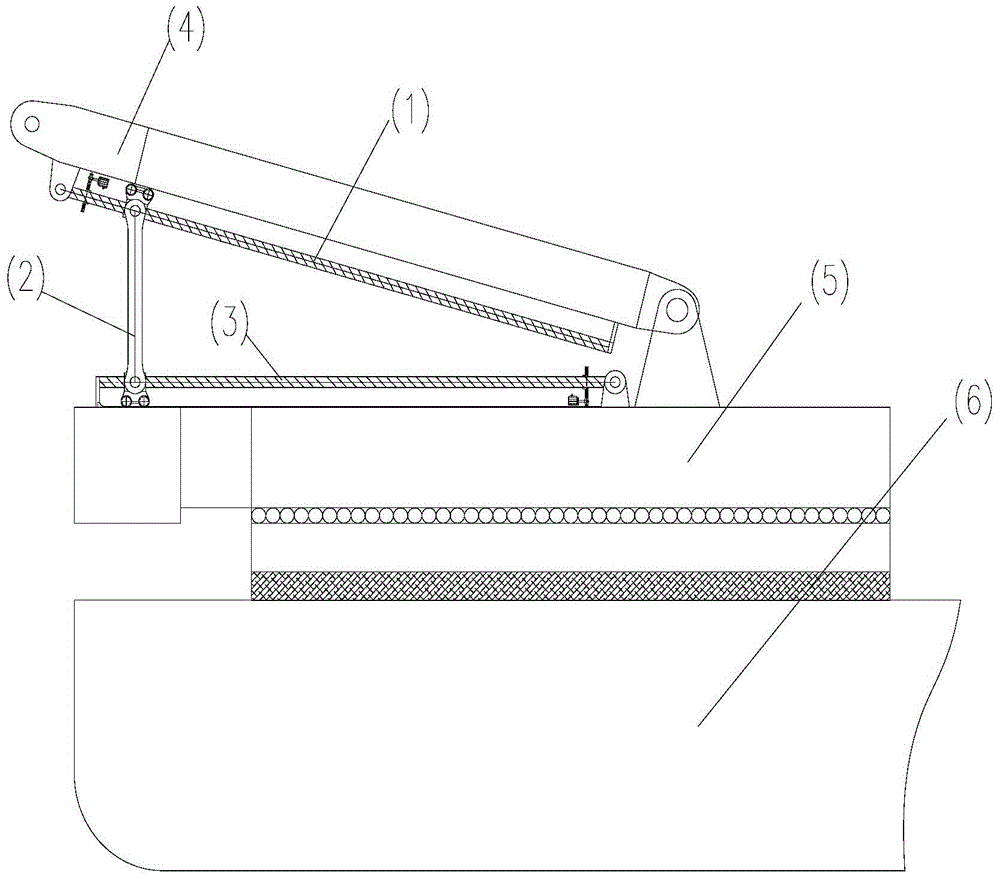

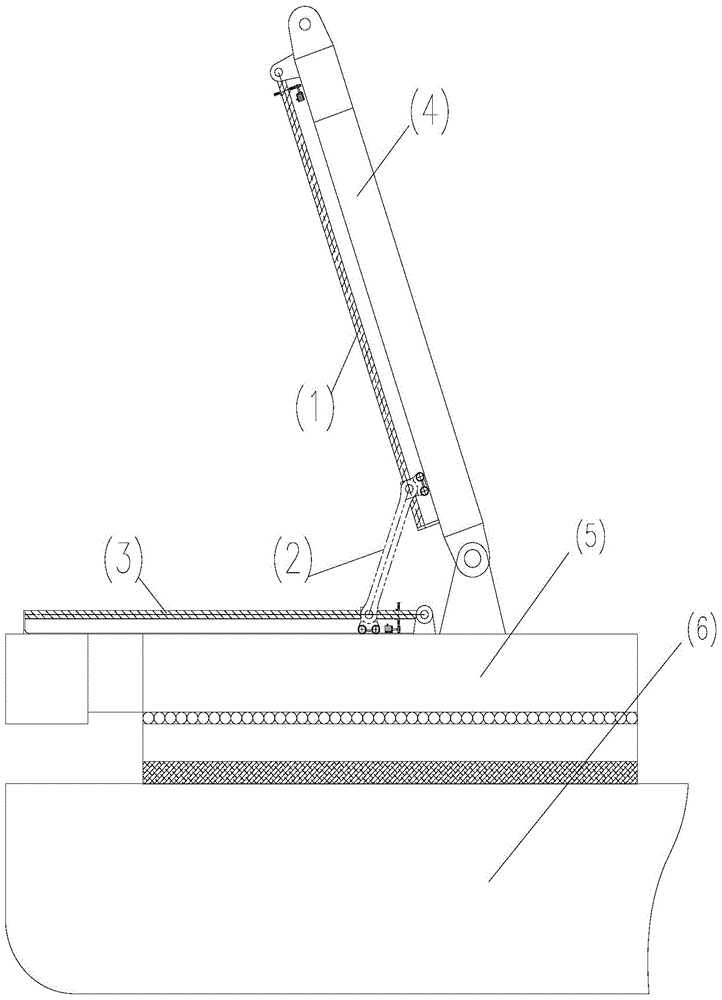

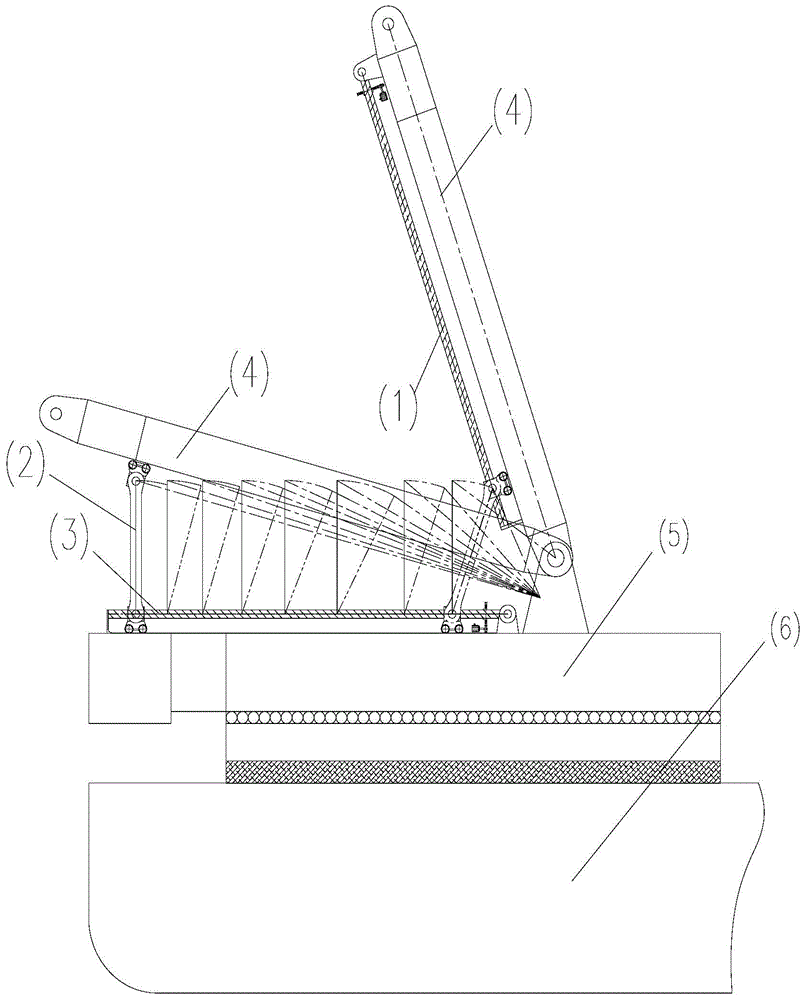

[0043] The specific embodiment of the present invention is shown in the attached drawings, including: the herringbone 4, the platform 5 and the hull 6, the platform 5 is mounted on the hull 6, and the herringbone 4 is hinged on the platform 5; it is characterized in that the herringbone The lower part of 4 is equipped with the upper screw assembly 1; the upper part of the platform 5 is equipped with the lower screw assembly 3 at the position corresponding to the upper screw assembly 1; the upper and lower ends of the load-bearing bracket 2 are hinged to the upper screw assembly 1 The upper guide wheel group 7 on the upper and the lower guide wheel group 16 on the lower screw assembly 3.

[0044] The upper screw assembly 1 includes: an upper guide wheel group 7, an upper screw 10, an upper guide 11 and an upper driving device 12; the upper guide 11 is installed on the chevron 4, the upper screw 10 is installed on the chevron 4; the upper drive The device 12 is installed on the che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com