Foam board addition device, container loader and container loading method

A technology of foam boards and cartons, applied in the field of box packing machines, can solve the problems of increasing production costs, etc., and achieve the effects of improving production efficiency, precise control, and smooth delivery of foam boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

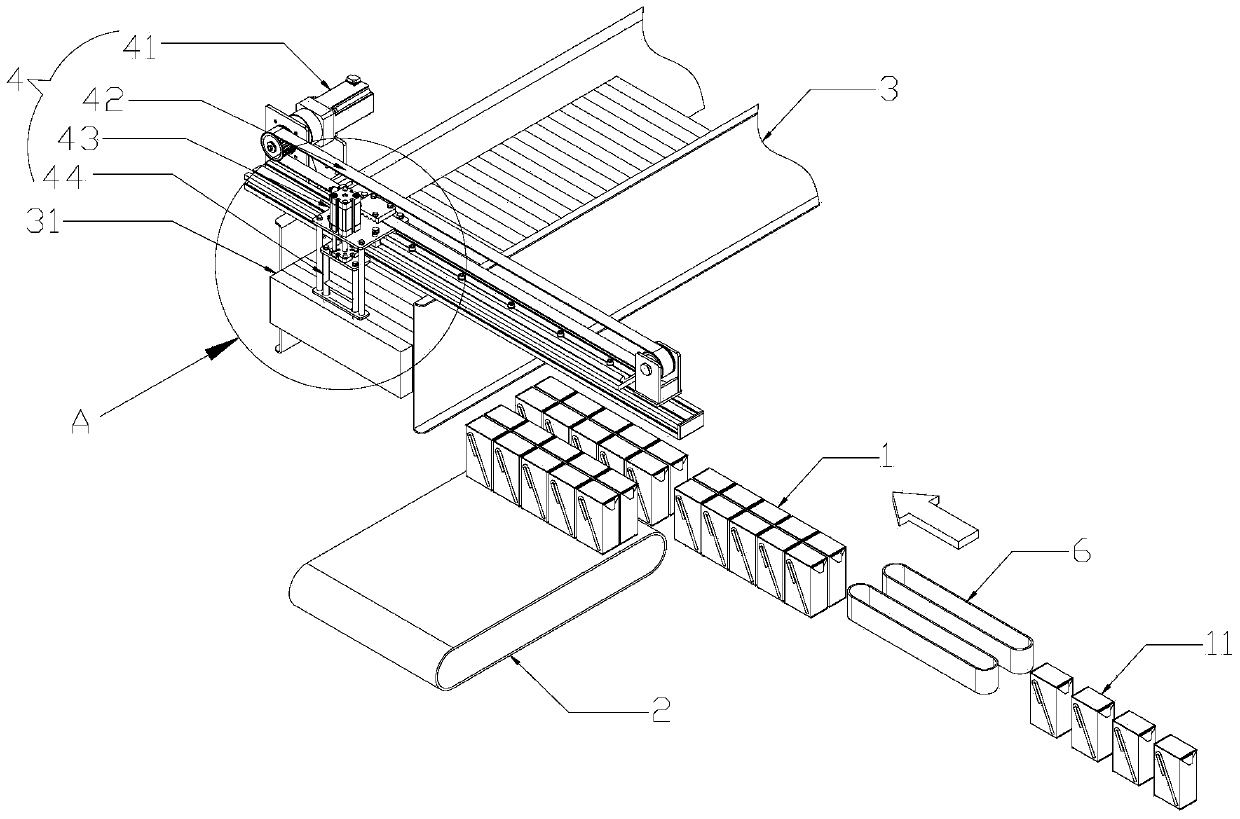

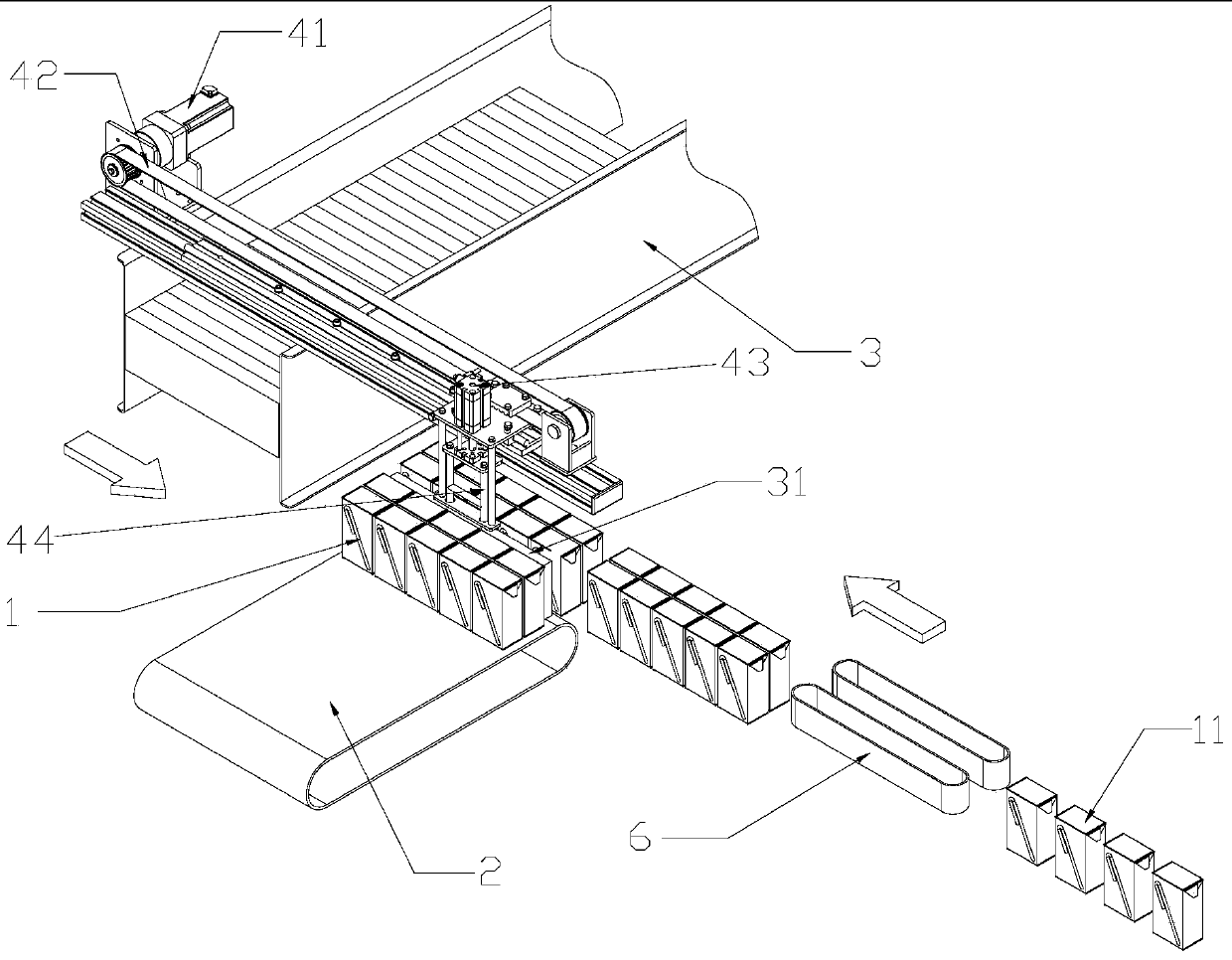

[0049] Please refer to Figure 1-6 As shown, a device for adding foam boards includes: a stacking assembly 2, a foam board warehouse 3, a foam board conveying assembly 4, a pushing assembly 5 and a control system. in:

[0050] The foam board warehouse 3 is placed on one side of the stacking assembly 2 , and the pushing assembly 5 is installed at the input end of the stacking assembly for pushing the product group 1 onto the stacking assembly 2 .

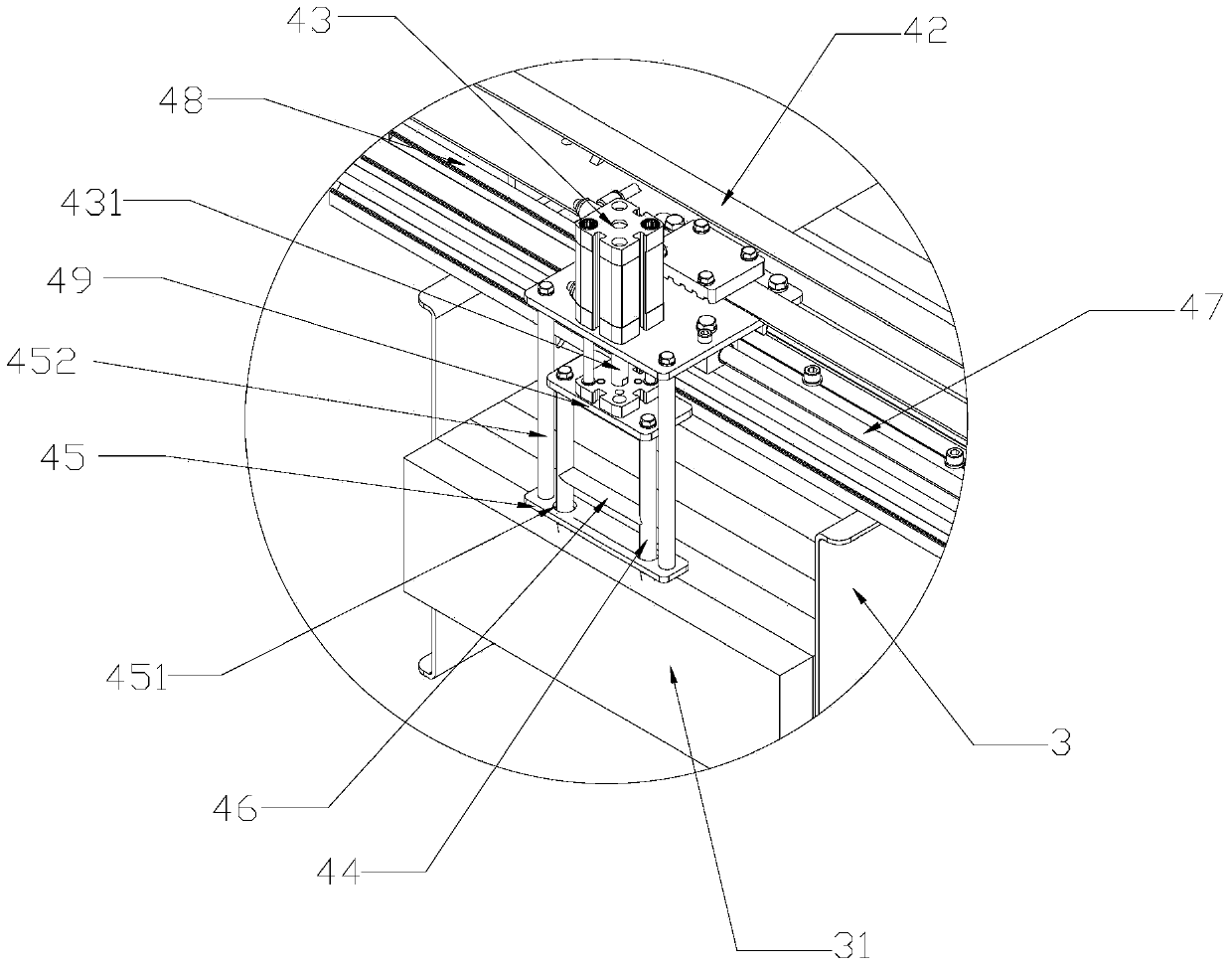

[0051] The foam plate delivery assembly 4 comprises a drive motor 41, a conveyor belt 42, a lifting cylinder 43 and pins 44, the conveyor belt 42 is arranged on the upper side of the stacking assembly 2 and the foam plate warehouse 3, and the drive motor 41 is connected with the conveyor belt 42 to drive the conveyor belt 42 Movement, the lifting cylinder 43 is fixedly installed on the conveyor belt 42, and the movable end 431 of the lifting cylinder 43 is fixedly connected with the pin 44 so that the lifting cylinder 43 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com