Drilling and boring integrated deep hole machining device

A processing device and deep hole technology, used in metal processing equipment, drilling/drilling equipment, drilling and other directions, can solve the problems of low processing accuracy, easy breakage of drill bits, low production efficiency, etc., to ensure the straightness of processing. and the effect of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

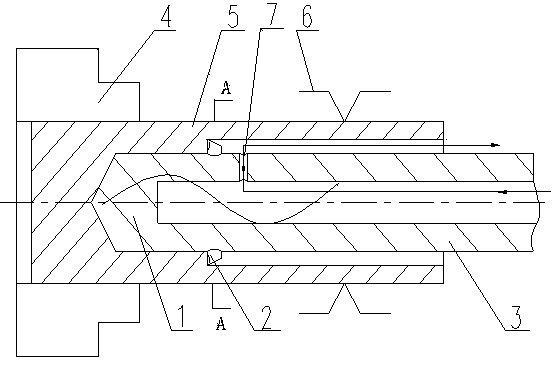

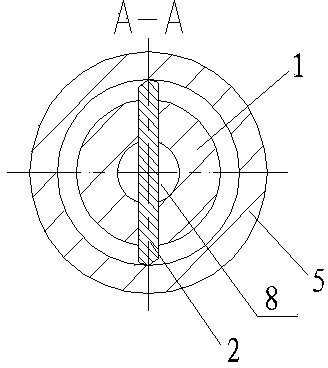

[0014] see figure 1 and figure 2 , the drill bit 1 is connected to the cutter bar 3, and a boring tool 2 is installed at the radial position of the drill bit 1, and the boring tool 2 passes through the shaft center line of the drill bit 1, and the cutter bar 3 is provided with a circulating cooling mechanism .

[0015] The circulation cooling mechanism includes a coolant inlet hole 7 and a cutter bar inner chamber 8 communicating therewith. The coolant inlet hole 7 is arranged in the axial direction of the cutter holder 3 and is perpendicular to the cutter holder inner chamber 8 .

[0016] The drill bit 1 and the cutter bar 3 are welded as one.

[0017] The boring tool 2 is installed on the drill bit 1 through a mounting hole.

[0018] The drill bit 1 of the present invention is used to drill out the rough-machined deep hole par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com