High-efficiency emulsifying machine capable of guaranteeing emulsifying effect

An emulsifying machine, high-efficiency technology, applied to mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve the problems of long time consumption, complicated operation, poor emulsification effect, etc., to achieve convenient operation, The effect of short operating time and high industrial practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

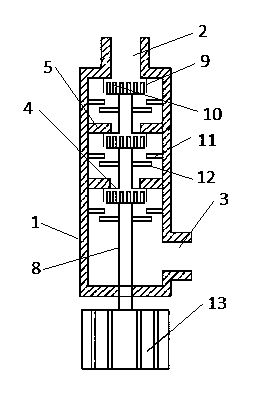

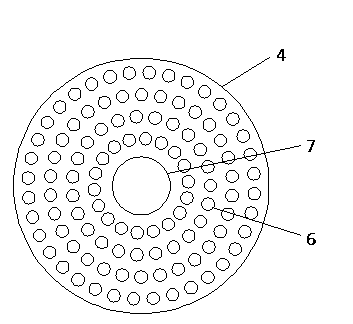

[0014] Such as Figure 1-2 The high-efficiency emulsification machine shown that can ensure the emulsification effect includes an emulsification chamber 1, a stator and a rotor. The rotor is connected to a motor 13. The emulsification chamber 1 is provided with a feeding port 2 above and a discharge port 3 below. Its characteristics That is, the emulsification chamber 1 is divided into multiple layers by the separators 5 with the filter screens 4 arranged in the middle, and the radii of the holes 6 of the filter screens 4 arranged from top to bottom decrease successively, and the middle of the filter screens 4 is evenly spaced. A round hole 7 for the passage of the rotor connecting rod 8 is provided. When the material is put into emulsification, the particles that have been sheared and broken to a certain size can pass through the filter screen and enter the next layer for further emulsification. The radius of the filter screen holes decreases from top to bottom, which can con...

Embodiment 2

[0016] Such as Figure 1-2 The high-efficiency emulsification machine shown that can ensure the emulsification effect includes an emulsification chamber 1, a stator and a rotor. The rotor is connected to a motor 13. The emulsification chamber 1 is provided with a feeding port 2 above and a discharge port 3 below. Its characteristics That is, the emulsification chamber 1 is divided into multiple layers by the separators 5 with the filter screens 4 arranged in the middle, and the radii of the holes 6 of the filter screens 4 arranged from top to bottom decrease successively, and the middle of the filter screens 4 is evenly spaced. A round hole 7 for the passage of the rotor connecting rod 8 is provided. When the material is put into emulsification, the particles that have been sheared and broken to a certain size can pass through the filter screen and enter the next layer for further emulsification. The radius of the filter screen holes decreases from top to bottom, which can con...

Embodiment 3

[0018] Such as Figure 1-2 The high-efficiency emulsification machine shown that can ensure the emulsification effect includes an emulsification chamber 1, a stator and a rotor. The rotor is connected to a motor 13. The emulsification chamber 1 is provided with a feeding port 2 above and a discharge port 3 below. Its characteristics That is, the emulsification chamber 1 is divided into multiple layers by the separators 5 with the filter screens 4 arranged in the middle, and the radii of the holes 6 of the filter screens 4 arranged from top to bottom decrease successively, and the middle of the filter screens 4 is evenly spaced. A round hole 7 for the passage of the rotor connecting rod 8 is provided. When the material is put into emulsification, the particles that have been sheared and broken to a certain size can pass through the filter screen and enter the next layer for further emulsification. The radius of the filter screen holes decreases from top to bottom, which can con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com