Drying device used for dried P.tianmuensis Z.P.Wang processing

A technology for drying equipment and green bamboo shoots, which can be used in applications, food processing, food science, etc., and can solve problems such as high energy consumption, long time, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

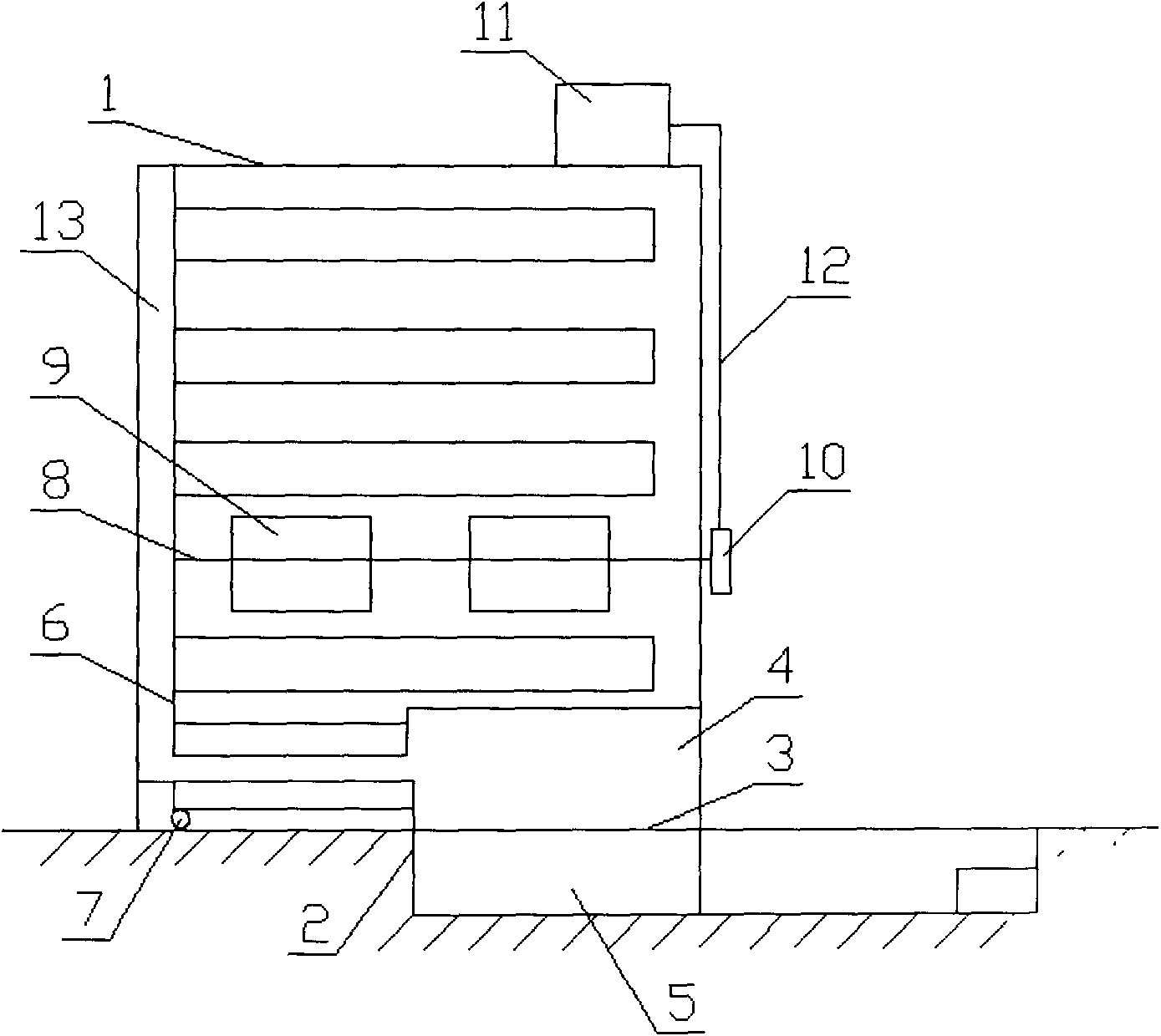

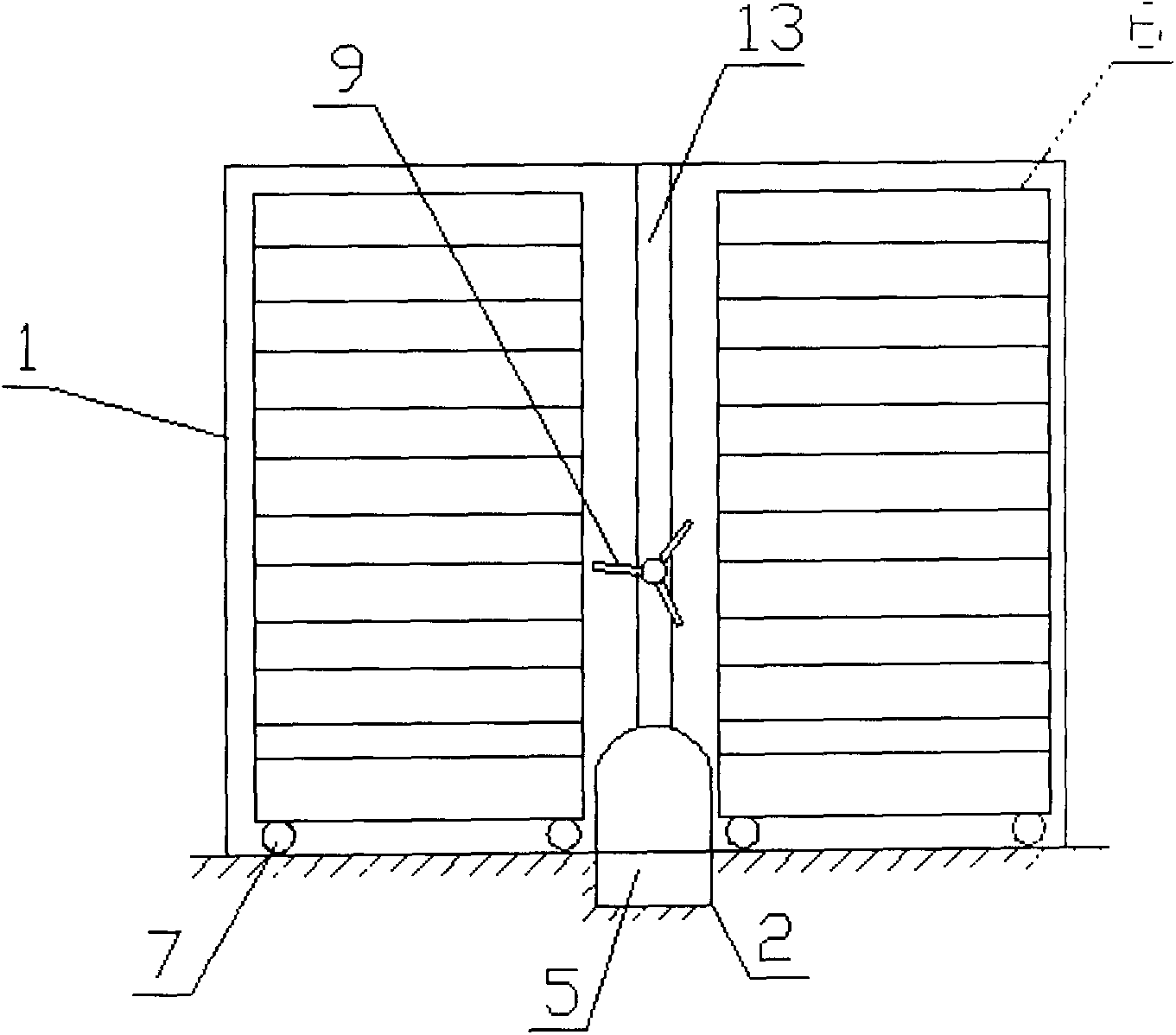

[0016] see figure 1 and figure 2 As shown, a drying device for processing green bamboo shoots of the present invention includes a rectangular three-dimensional oven body 1, and a combustion chamber heat source furnace 2 arranged directly below the oven body 1. The combustion chamber heat source furnace 2 is rectangular , the upper circle and the lower structure, separated by a grate 3 in the middle, the upper layer is a combustion chamber 4, and the lower layer is a lime chamber 5, which is installed in a trough. The oven body 1 is provided with more than one and is vertically separated by a steel frame structure. The drying rack 6 is equipped with a roller 7 at the bottom of the drying rack 6, and a bamboo movable drying bar is placed on the drying rack 6. The drying rack 6 is symmetrically placed in the oven body 1, and the middle passes through the combustion chamber 4. Separated, a thermal rotary system is installed in the middle of the oven body 1, and the thermal rotar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com