Intelligent feeding system used for passive direct methanol fuel cell

A methanol fuel cell and feeding system technology, applied in the direction of fuel cell additives, etc., can solve the problems of blocked two-phase mass transfer at the two poles of the battery, limit the performance of DMFC, and low reaction temperature, so as to promote vaporization and boiling, facilitate installation and use, and speed up The effect of responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples.

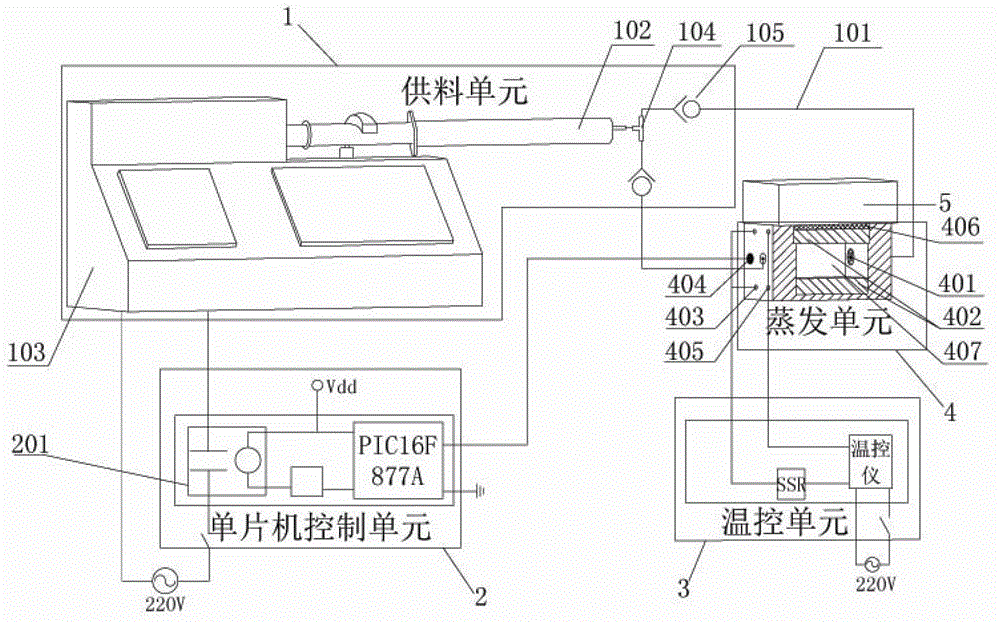

[0025] see figure 1 and figure 2 As shown, the intelligent feeding system for passive direct methanol fuel cells described in this embodiment includes a feeding unit 1, a single-chip microcomputer control unit 2, a temperature control unit 3, and an evaporation unit 4, wherein the feeding unit 1 Connect the spray nozzle 401 of the evaporating unit 4 through the infusion joint 101, so that the liquid fuel delivered to the evaporating unit 4 can be sprayed in the form of mist. The evaporating unit 4 is provided with a boiling enhancement plate 402, and the boiling enhancement plate 402 is formed The heating rod 403 of the evaporating unit 4 is heated to increase the temperature, which can vaporize the mist fuel into steam fuel; the single-chip microcomputer control unit 2 is respectively connected with the pressure sensor 404 of the evaporating unit 4 and the feeding unit 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com