Capacitive touch screen

A technology of capacitive touch screen and touch point, which is applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve problems such as easy generation of air bubbles and affect the service life of the touch screen, and achieve life guarantee , the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

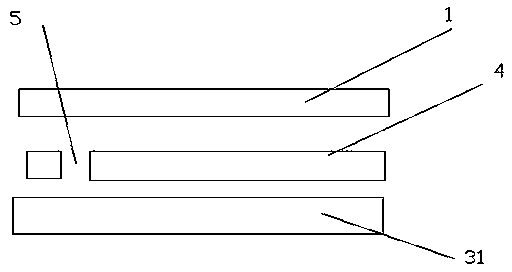

[0026] see figure 1 with figure 2 , a capacitive touch screen comprising: a display screen 2 on the bottom layer for displaying images; a cover plate Cover Lens1 on the top layer for protecting the nano-indium tin metal oxide ITO sensor 3, the Cover Lens1 is made of tempered Made of glass; the ITO sensor 3 is located between the display screen 2 and the Cover Lens1, and the ITO sensor 3 is composed of one layer of ITO Film31; the Cover Lens1 and the ITO sensor 3 are bonded together by optical double-sided adhesive OCA4; A hole 5 for placing a button icon is dug on the OCA4. The size of the hole 5 is 200 microns wider than the actual size of the button icon (not shown), and the hole 5 is a through hole.

[0027] Wherein, the capacitive touch screen further includes a flexible circuit board 6 connected to the ITO sensor 3 for calculating touch points and reporting them back to the processor.

[0028] In the capacitive touch screen provided in this embodiment, the size of the ...

Embodiment 2

[0030] see figure 1 with figure 2 , a capacitive touch screen comprising: a display screen 2 on the bottom layer for displaying images; a cover plate Cover Lens1 on the top layer for protecting the nano-indium tin metal oxide ITO sensor 3, the Cover Lens1 is made of tempered Made of glass; the ITO sensor 3 is located between the display screen 2 and the Cover Lens1, and the ITO sensor 3 is composed of one layer of ITO Film31; the Cover Lens1 and the ITO sensor 3 are bonded together by optical double-sided adhesive OCA4; A hole 5 for placing a button icon is dug on the OCA4. The size of the hole 5 is 40 microns wider than the actual size of the button icon (not shown), and the hole 5 is a through hole.

[0031] Wherein, the capacitive touch screen further includes a flexible circuit board 6 connected to the ITO sensor 3 for calculating touch points and reporting them back to the processor.

[0032] In the capacitive touch screen provided in this embodiment, the size of the h...

Embodiment 3

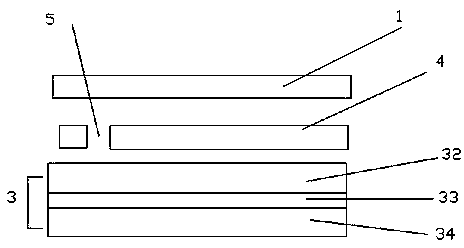

[0034] refer to figure 1 and image 3, a capacitive touch screen, comprising: a display screen 2 on the bottom layer for displaying images; a cover plate Cover Lens1 on the top layer for protecting the nano-indium tin metal oxide ITO sensor 3, and the Cover Lens1 is composed of Made of tempered glass; the ITO sensor 3 is located between the display screen 2 and Cover Lens1 for sensing touch points; the ITO sensor 3 is composed of two layers of ITO Film (32, 34); wherein, towards the The ITO Film32 on one side of the Cover Lens1 is bonded together with the Cover Lens1 through the optical double-sided adhesive OCA4; the two layers of ITO Film (32, 34) of the ITO sensor 3 are bonded together through the second OCA33, and the first Two, the thickness of OCA33 is 70 microns; the OCA4 is dug with a hole 5 for placing a button icon, and the size of the hole 5 is 500 microns wider than the actual size of the button icon, and the hole 5 is a through hole. The capacitive touch screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com