Device for testing wiring harness resistance under constant temperature state

A resistance test and state technology, applied in the direction of measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve the problems of temperature guarantee and selection of clamping methods, so as to improve test efficiency and ensure test quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

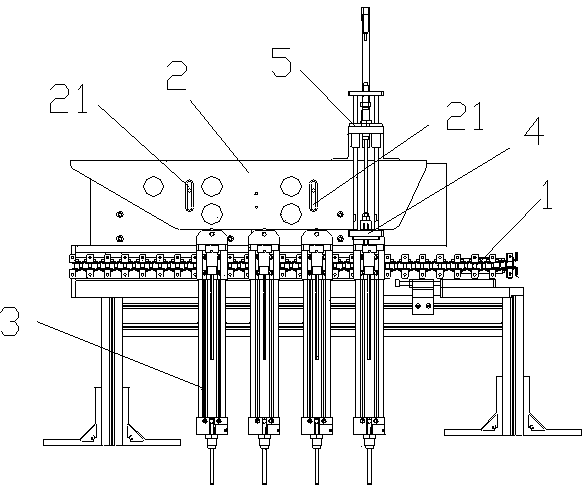

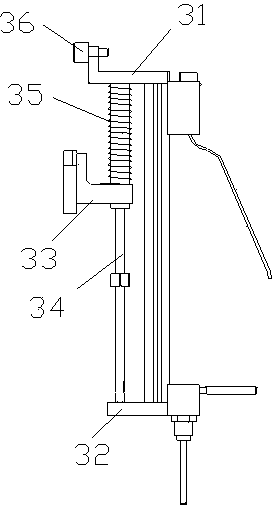

[0017] like figure 1 and figure 2 As shown, a wire harness resistance testing device under a constant temperature state includes a transmission chain 1 and a wire harness clamping device 3 fixed on the transmission chain 1 at equal intervals. An inverted trapezoidal guide block 2 is arranged above the transmission chain 1. A resistance testing device 4 for pressing down is arranged above the inverted trapezoidal guide block 2 .

[0018] By setting an inverted trapezoidal guide block 2 above the transmission chain 1, the wire harness clamping device 3 is pressed down when passing through the inverted trapezoidal guide block 2, so that the lower end of the wire harness extends into the thermostatic box below (not shown in the figure) ), at the same time, it is possible to control the time when the wire harness extends into the incubator by selecting the inverted trap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com