Carrier component with integrated sensor unit

A technology of sensor unit and sensor device, which is applied in the direction of vibrating fluids, instruments, vehicle parts, etc., can solve the problems of sensor system manufacturing cost and complex structure of sensor unit, and achieve the effect of easy production and avoiding seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

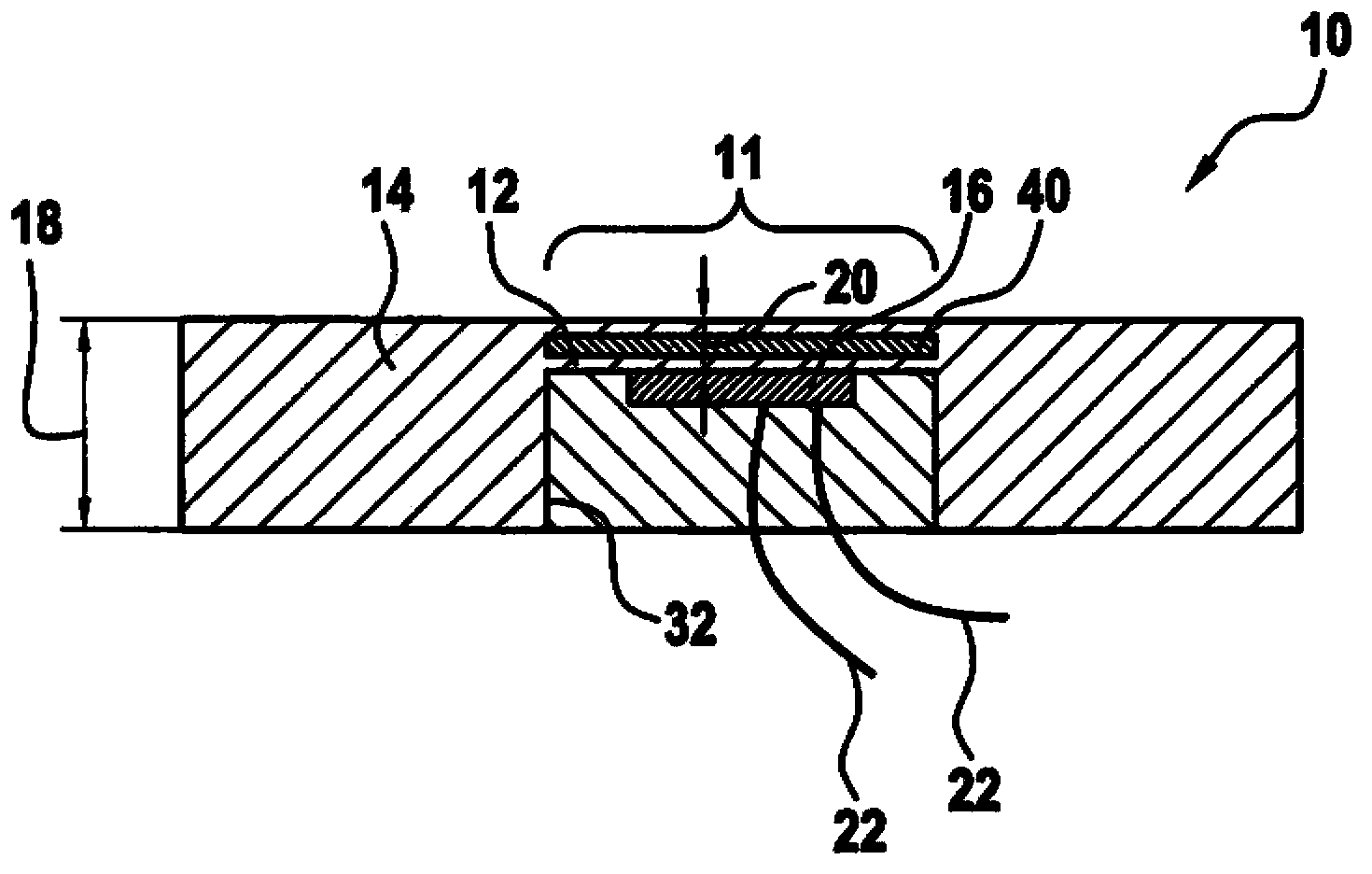

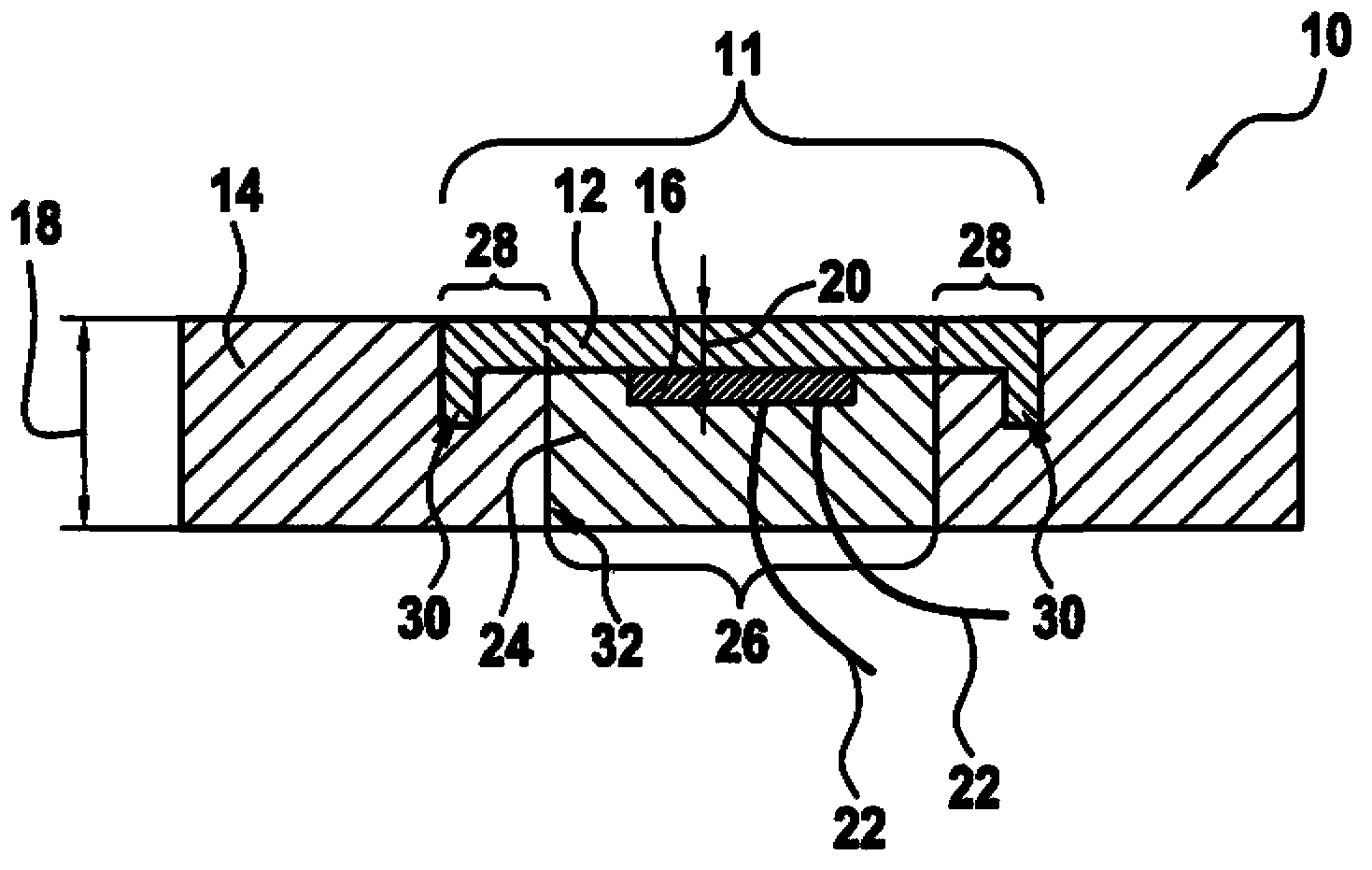

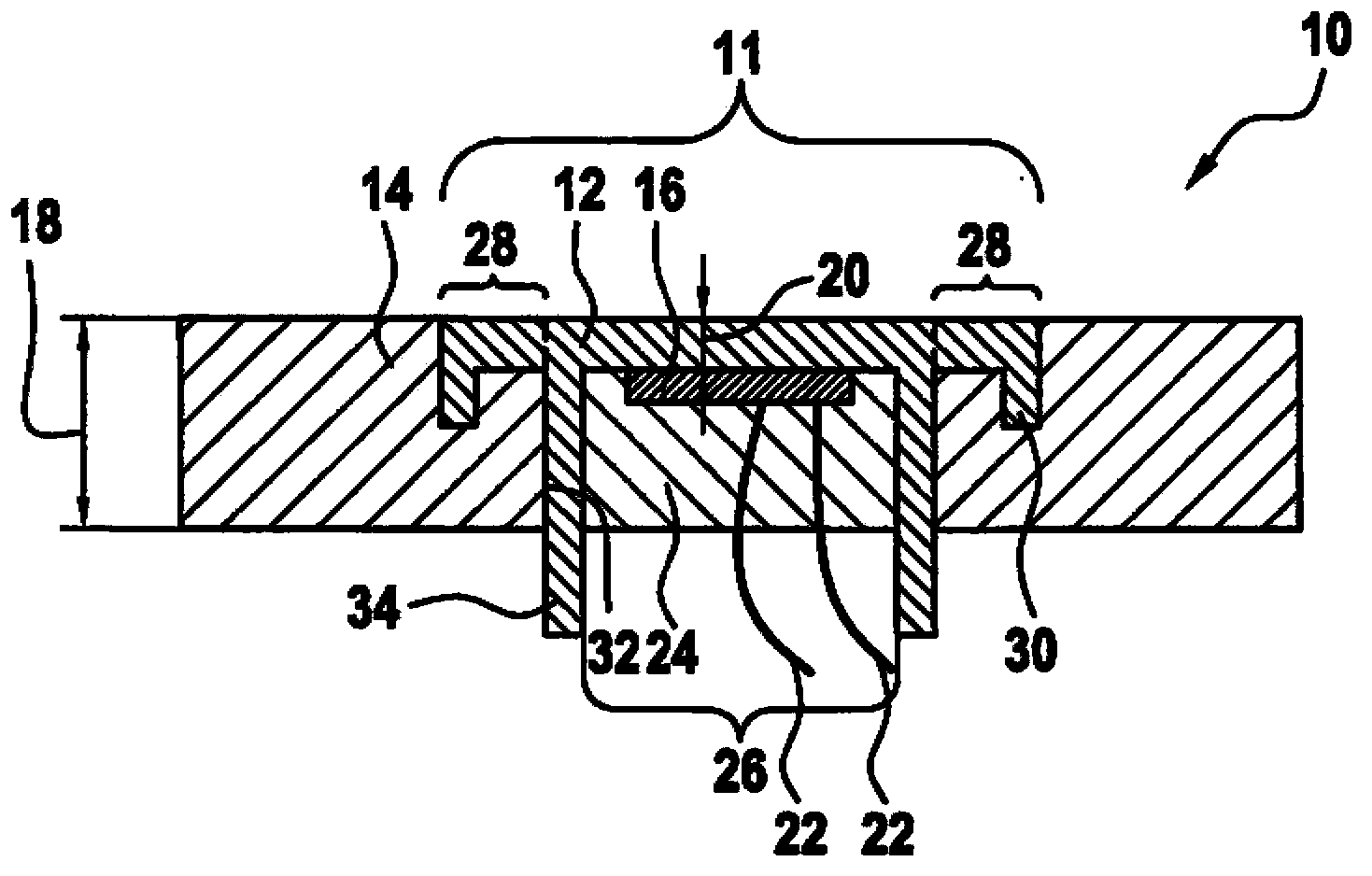

[0047] figure 1 A sensor arrangement 10 is shown, wherein the sensor unit 11 forms part of a bumper 14 . The sensor unit 11 is realized here as an ultrasound transducer with a membrane 12 and a piezoelectric actuator 16 . Furthermore, the membrane 12 is formed by the bumper 14 itself, in that the bumper 14 is designed with a smaller wall thickness 20 in the region of the sensor unit 11 and a fiber mat 40 is embedded in this region. The fiber mat 40 is preferably embedded in the bumper 14 during its injection. The fiber mat can be arranged in the region of the cutout 32 or the edge extends beyond this region, said cutout being formed by the small wall thickness of the carrier element. As a result, the area of the diaphragm 12 can be configured more intensively and typical parameters of the sensor unit, such as the resonance frequency, can be adapted. In order to transmit and / or receive ultrasonic signals, the piezoelectric actuator 16 is directly connected to the bumper 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com