Fixing structure of light bars in LED (light-emitting diode) backlight module

A technology of LED light bar and backlight module, which is applied in the field of TV, can solve the problems of complex fixed structure and inconvenient installation, and achieve the effect of simple installation, not easy to slide out, and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

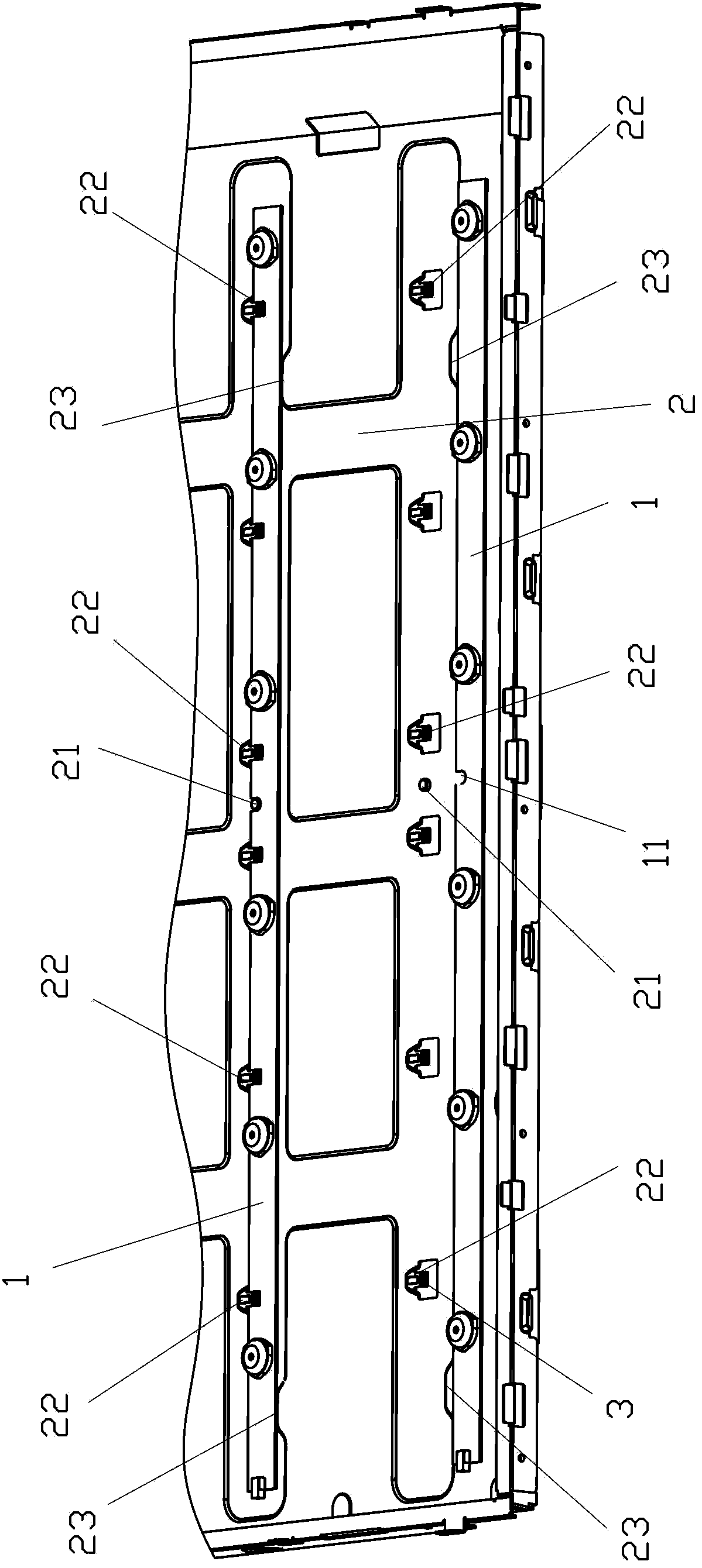

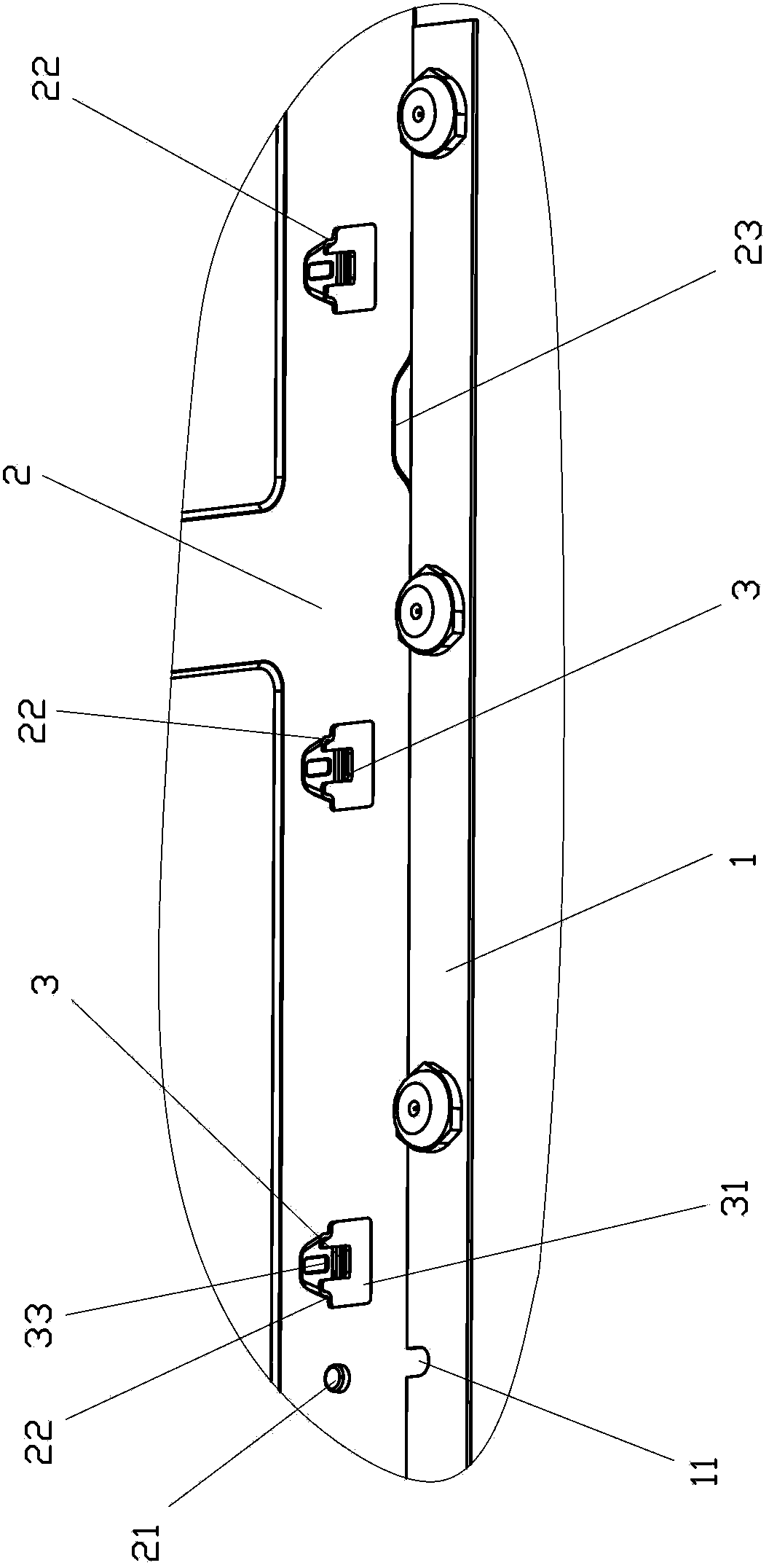

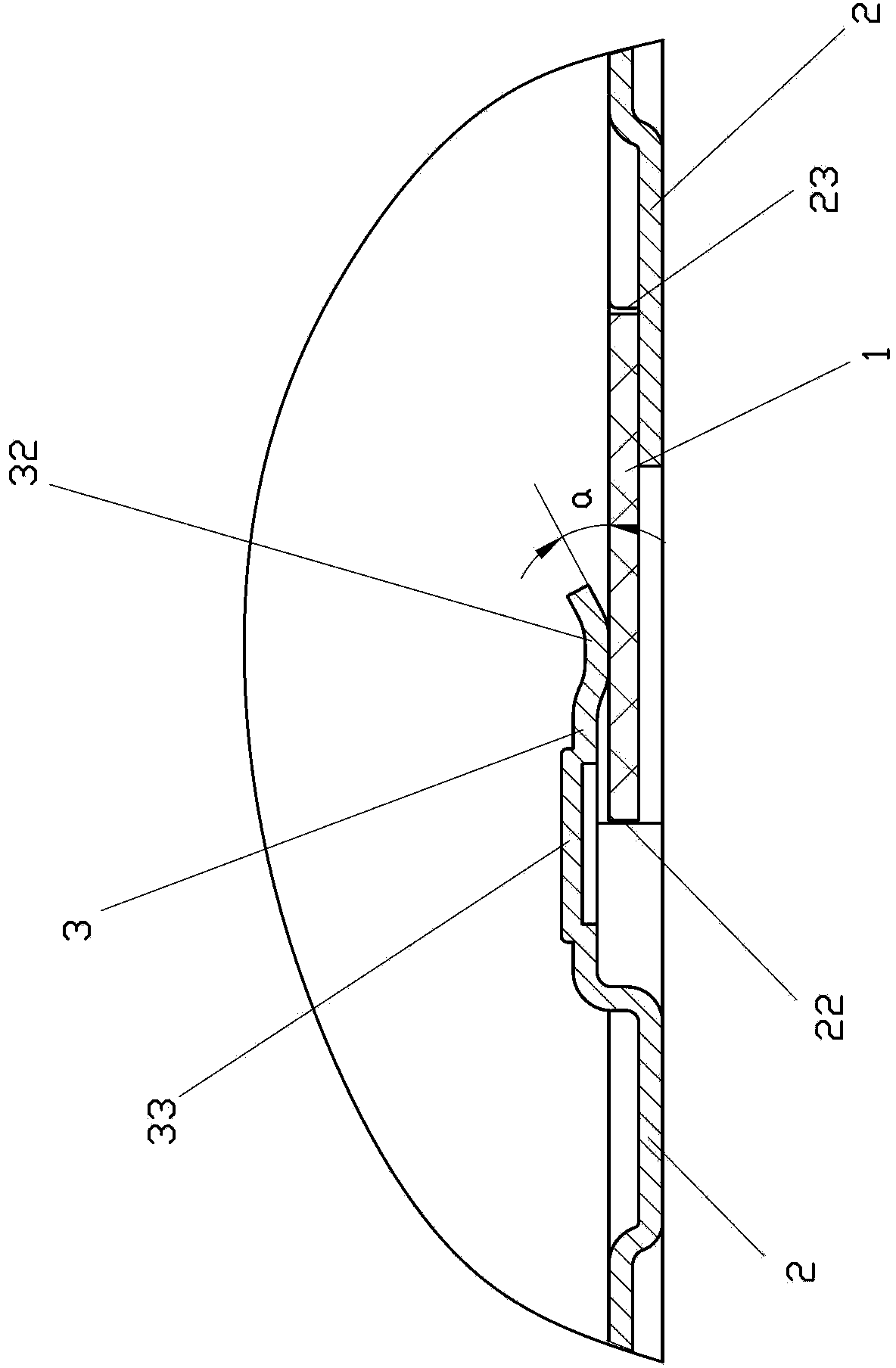

[0019] Examples, see Figure 1 to Figure 3 As shown, the fixing structure of the light bar in a kind of LED backlight module of the present invention comprises:

[0020] The LED light bar PCB board 1, at least one U-shaped groove 11 is provided on the edge of one of the long sides of the LED light bar PCB board 1;

[0021] The hardware backboard 2 is provided with a positioning post 21 formed by stamping and adapted to the U-shaped groove of the LED light bar PCB at the installation place corresponding to the LED light bar PCB board in the hardware backboard 2 . Corresponding to one of the long sides of the LED light bar PCB board, there are several first limiting protrusions 22 formed by stamping, and there are several first limiting convex hulls 22 corresponding to the other long side of the LED light bar PCB board in the hardware backboard. The second limiting convex hull 23 formed by stamping is used, and the two long sides of the LED light strip PCB board respectively ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bend angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com