Small leakage detection system for liquid pipeline

A leak detection and detection system technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of liquid pipeline leakage, difficult implementation of buried pipelines, and large non-real-time detection workload, to prevent The effect of enlarged leakage, reduced fluid loss, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

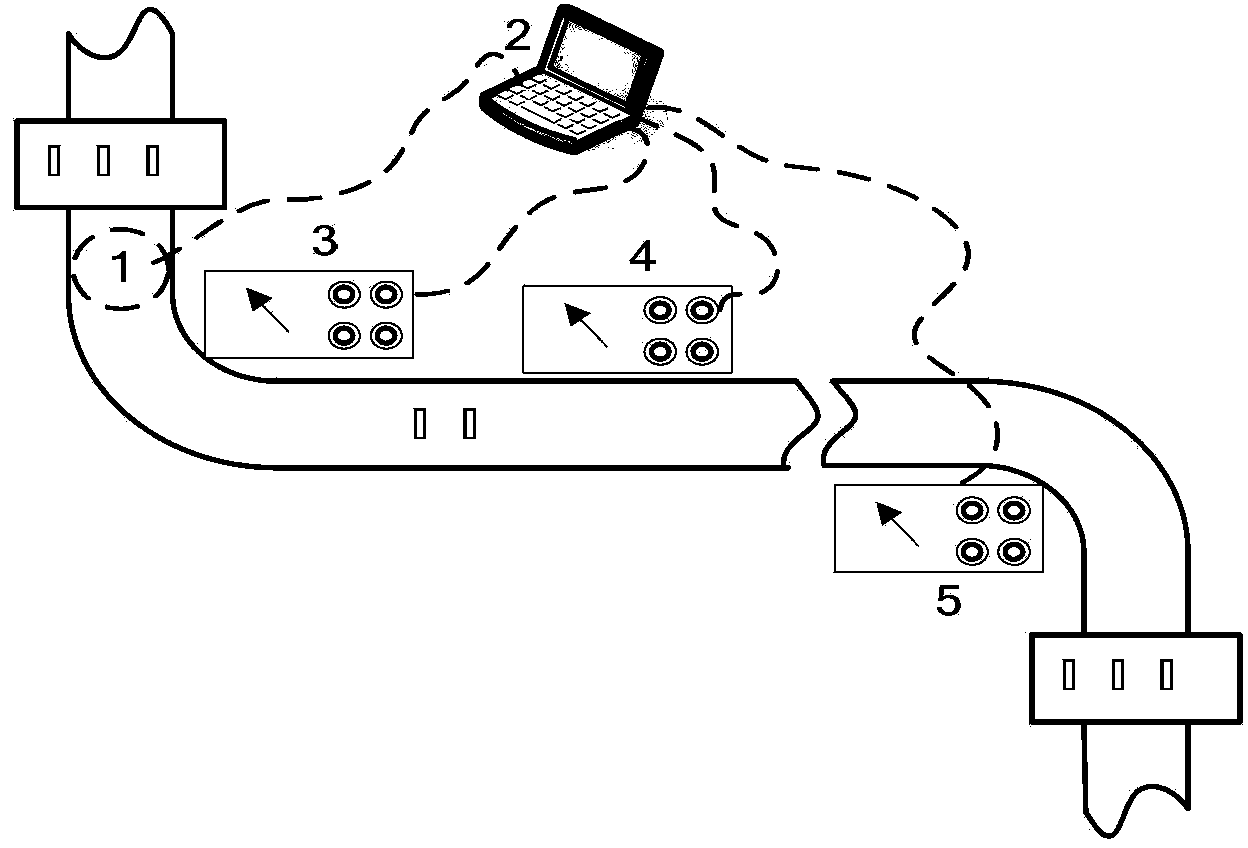

[0062] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. This example is an experimental prototype, its composition is as follows figure 1 shown. The system of the present invention constitutes as figure 1 As shown, the leak detection ball 1, multiple ground markers I 3, ground marker II 4, ground marker III 5, host computer 2, ball receiving and sending devices. The leak detection ball 1 is launched by the pigging device, and the leak detection ball 1 flows together with the medium in the pipeline. At the same time, the sound signal in the pipe and the state information of the leak detection ball are collected and saved, and time stamped. After being withdrawn from the ball collecting device, it is connected with the host computer, and judges whether there is leakage and the position of leakage by the host computer 2 leakage identification and positioning software.

[0063] Before lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com