Backflow-type detachable wear-resisting elbow

A backflow and elbow technology, applied in the direction of elbows, pipes/pipe joints/fittings, pipelines to prevent damage/abrasion, etc., can solve problems such as weak wear resistance, prolong service life, save use cost, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

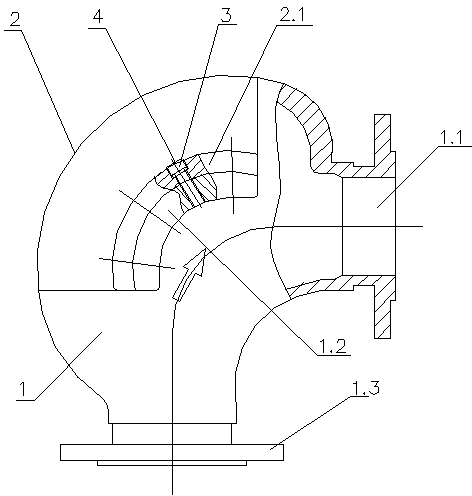

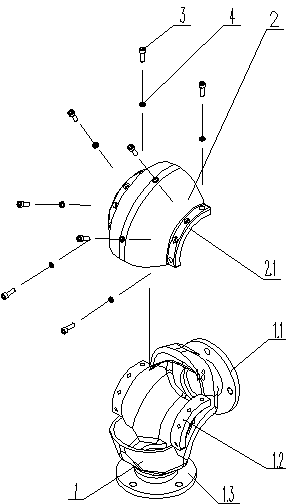

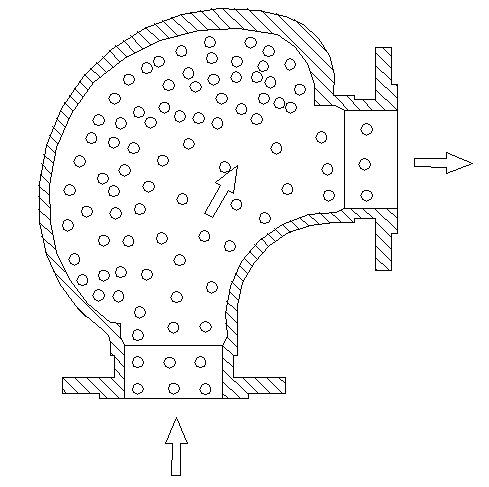

[0016] figure 1 and figure 2 The shown backflow detachable anti-wear elbow is composed of a shell 1, a top cover 2, a bolt 3 and a washer 4. The housing 1 is a right-angled pipe fitting with an inlet 1.3 and an outlet 1.1. The top cover 2 is an arc-shaped member bent along the wall of the housing 1. There is a gap on the outer curved wall of the housing 1 to seal and install the top cover 2. The two sides of the joint are respectively provided with a protruding cover edge 2.1 and The shell edge 1.2 and the paired edges are connected by bolts 3 and washers 4 to form a detachable structure. The casing 1 and the matching top cover 2 form an upwardly convex volute. The highest end of the volute is located on the upper wall of the neck of the outlet 1.1 and connected by an arc. The height difference between the two is equal to 0.5 to 1.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com