Mixed tower supporting structure capable of being used in large-size land wind generating set

A technology for wind turbines and support structures, which is applied to wind turbine components, wind engines, and wind power generation. It can solve problems such as increase in size, difficulty in transportation and manufacturing, and increase in cost, and achieve the effect of improving economic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

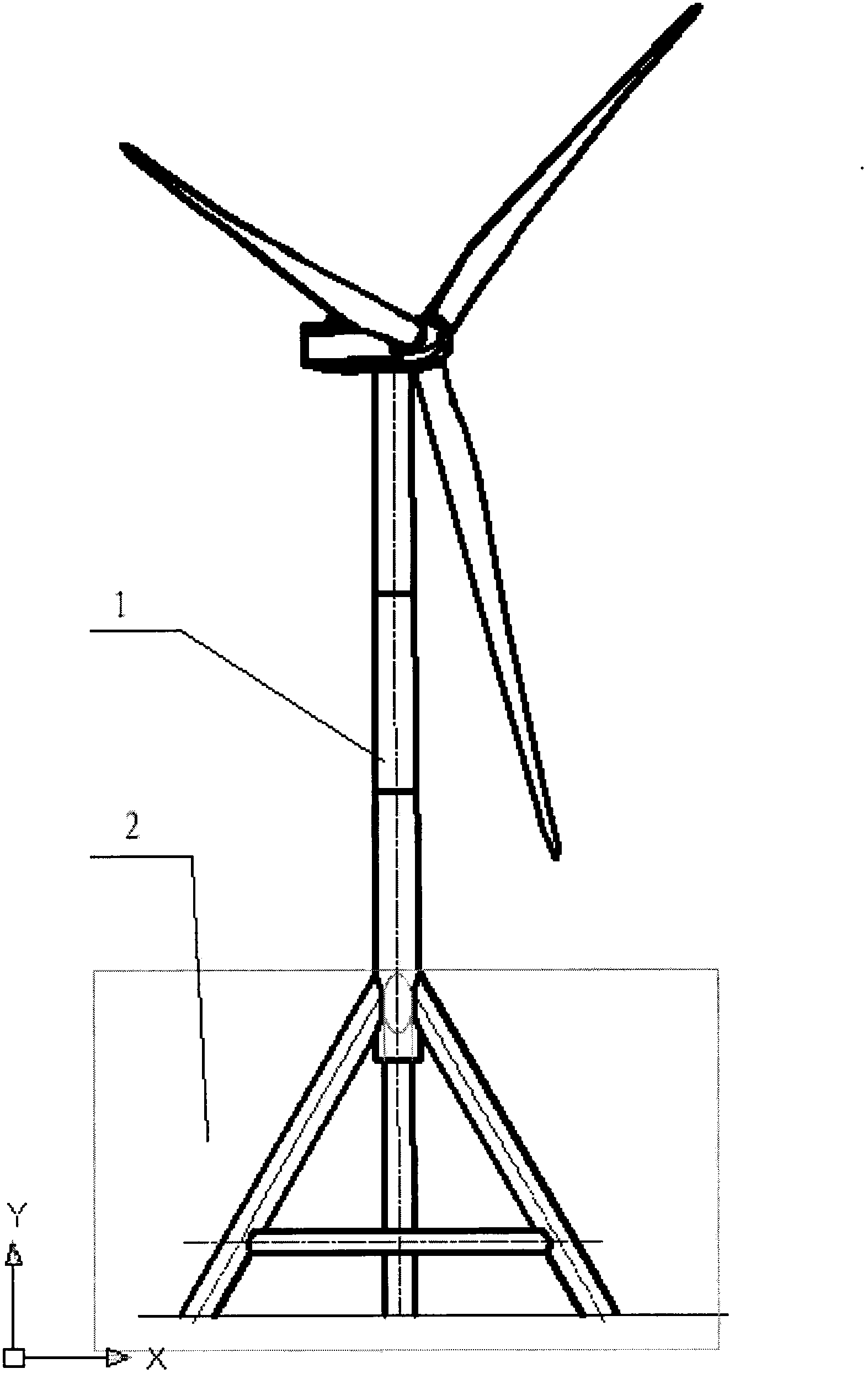

[0011] The picture is a schematic diagram of a hybrid tower support structure that can be used for large-scale onshore wind turbines. It can be seen from the figure that the hybrid tower is divided into two parts, and the upper part adopts a traditional conical steel cylinder tower (1) , the lower part adopts other supporting structures (2), and the two parts are connected together to form the supporting structure of the wind power generating set.

[0012] The other supportable structure (2) may be a jacket structure, a concrete structure, or a truss structure.

[0013] A hybrid tower support structure that can be used for large-scale land-based wind power generators according to the present invention can meet the tower design of wind power generators with different capacities and arbitrary heights through the combination of the two structures. For large-capacity wind power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com