Method for preparing large-particle picromerite

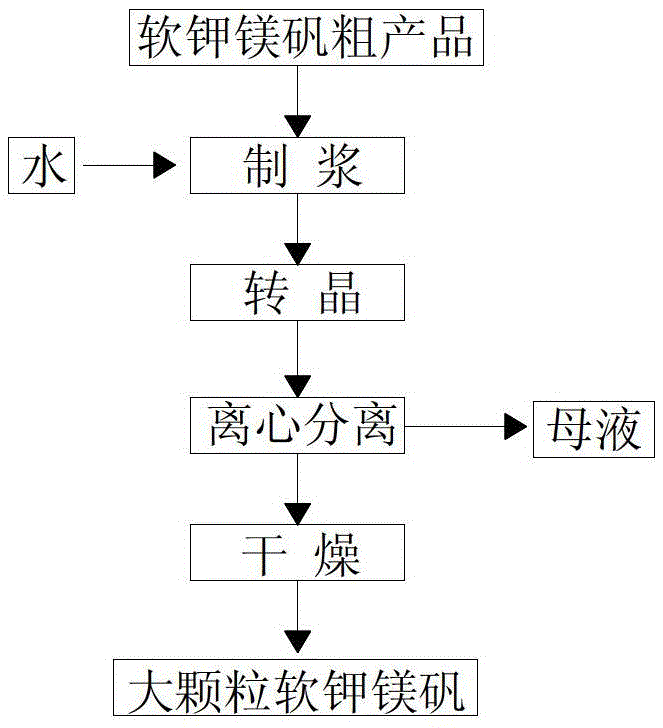

A technology of langbeinite and large particles, which is applied in the field of salt chemical industry, can solve the problems of easy agglomeration of dryness and difficult separation of fine particles of langbeinite, and achieves the effects of high yield, low energy consumption and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The first step, pulping

[0025] The composition (mass percentage) is: K + 19.00%, Mg 2+ 7.00%, Na + 0.80%, SO 4 2- 47.00%, Cl - 1.50% lenbeinite crude product (the rest is water, and there are 1-2% solid insolubles; the crude product is powder, particle size less than 200μm) and water are prepared into a slurry at a mass ratio of 1:0.30, the slurry The material temperature is controlled at 50°C;

[0026] The second step, turn the crystal

[0027] The slurry prepared in the first step is continuously put into the mother liquor at 20°C in the continuous crystallizer, the temperature in the crystallizer is kept at 20°C, and the mass ratio of kolinite and mother liquor in the crystallizer is controlled at 1:3 , and ensure that the slurry dropped into can have a residence time of 0.5 hour in the crystallizer, and the mass percent concentration of ions contained in the composition of the mother liquor is: K + =4.80%, Mg 2+ =2.60%, Na + =0.50%, Cl - =0.80% and SO ...

Embodiment 2

[0035] The first step, pulping

[0036] The composition (mass percentage) is: K + 17.08%, Mg 2+ 5.72%, Na + 1.67%, SO 4 2- 41.97%, Cl - 3.36% of the crude langbeinite and water are configured into a slurry at a mass ratio of 1:0.35, and the temperature of the slurry is controlled at 60°C;

[0037] The second step, turn the crystal

[0038] The slurry prepared in the first step is continuously put into the mother liquor at 25°C in the continuous crystallizer, the temperature in the crystallizer is kept at 25°C, and the mass ratio of kolinite and mother liquor in the crystallizer is controlled at 1:4.5 , and ensure that the slurry dropped into can have a residence time of 2.5 hours in the crystallizer, and the mass percentage concentration of ions contained in the composition of the mother liquor is: K + =4.59%, Mg 2+ =2.30%, Na + =1.60%, Cl - =4.75% and SO 4 2- =11.77%;

[0039] The third step, centrifugation

[0040] The large-grain langbeinite obtained in the se...

Embodiment 3

[0045] first step,

[0046] The composition (mass percentage) is: K + 16.00%, Mg 2+ 5.00%, Na + 2.00%, SO 4 2- 39.00%, Cl - 4.00% crude langbeinite and water are configured into a slurry at a mass ratio of 1:0.50, and the temperature of the slurry is controlled at 70°C;

[0047] The second step, cooling and crystallization

[0048] The slurry prepared in the first step is continuously put into the mother liquor at 30°C in the continuous crystallizer, the temperature in the crystallizer is kept at 30°C, and the mass ratio of kolinite and mother liquor in the crystallizer is controlled at 1:6 , and ensure that the slurry dropped into can have a residence time of 5 hours in the crystallizer, and the mass percent concentration of ions contained in the composition of the mother liquor is: K + =4.00%, Mg 2+ =2.00%, Na + =2.50%, Cl - =6.00% and SO 4 2- =11.00%;

[0049] The third step, centrifugation

[0050] The large-grain langbeinite obtained in the second step of crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com