Large ship deck mechanical brake structure and application method based on positioning device

A technology of mechanical brakes and ship decks, applied in ship construction, ship parts, transportation and packaging, etc., can solve the problems of difficult positioning of brake structures and low accuracy, and achieve the effects of improved safety factor, easy storage and reduced construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

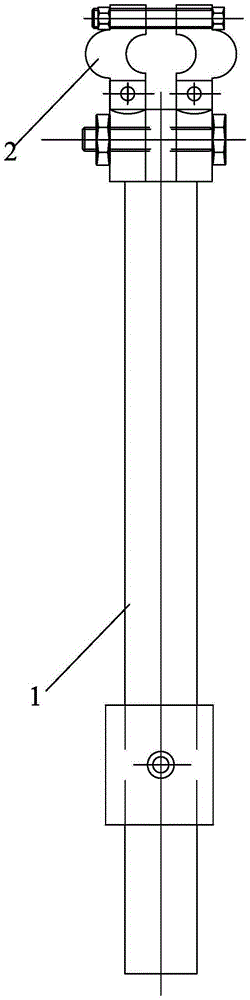

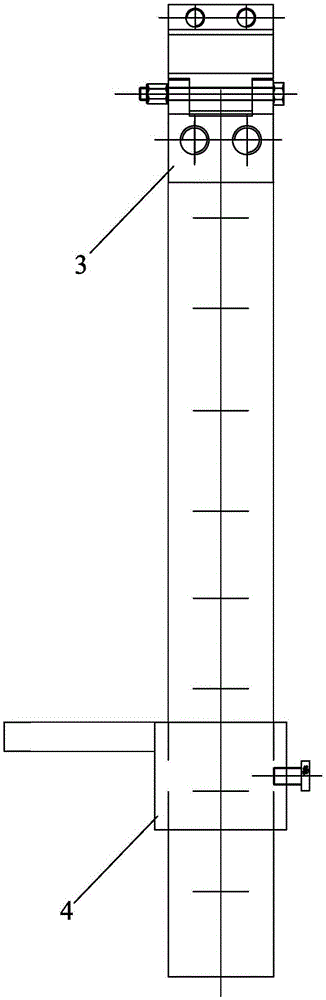

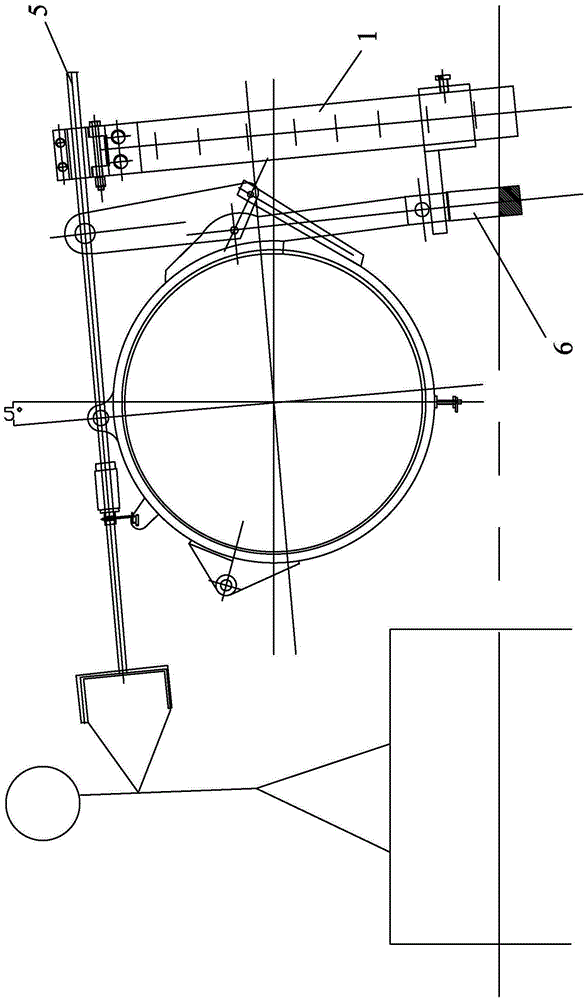

[0021] The present invention is based on the large ship deck mechanical braking structure of the positioning device, such as Figure 1-2 As shown, it includes the main scale 1, the splint 3 fixed on the main scale 1, the bolts and nuts used to fix the splint and the main scale, and the snap ring 2 connected to the splint 3 through the pin shaft and the nut . There are two splints 3 and snap rings 2, which are symmetrically installed on both sides of the main scale. The main scale 1 and the vernier 4 constitute the caliper assembly, figure 2 The vernier scale 4 that can facilitate the reading of the size and the tightening bolts used to lock the vernier scale are shown in . The auxiliary scale of the vernier scale 4 is strictly perpendicular to the main scale scale 1.

[0022] When in use, the splint 3 and the main scale 1 are first connected by bolts and nuts; then the splint 3 and the snap ring 2 are connected by a pin shaft and a nut, and after the snap ring 2 and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com