Multi-head drilling equipment comprising rotary table

A technology of drilling equipment and rotary table, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., which can solve the problem of high scrap rate of balance shaft processing and reduce installation and disassembly Number of times, guaranteed accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

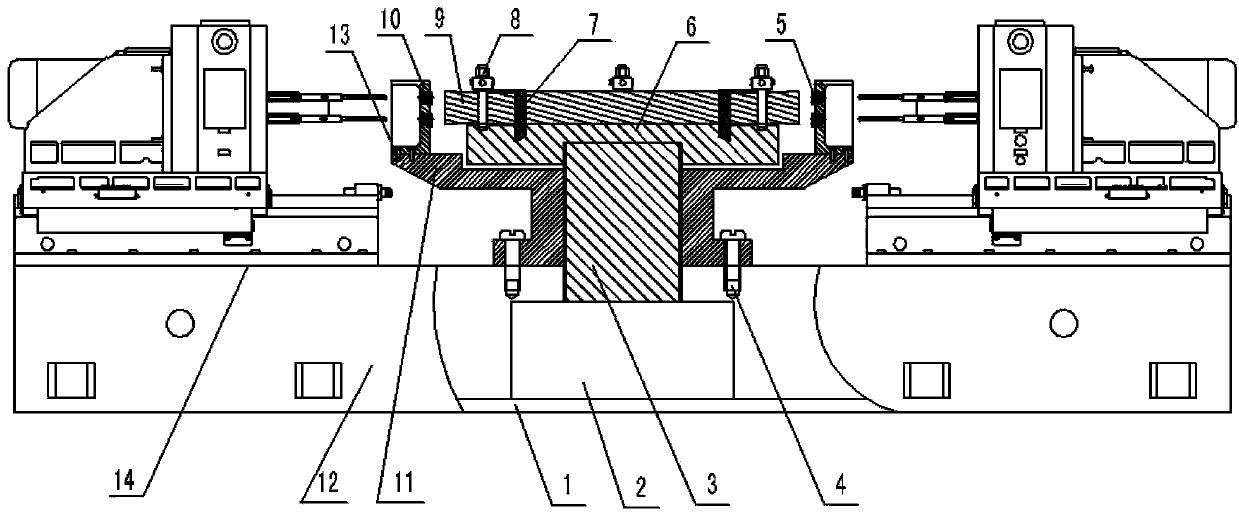

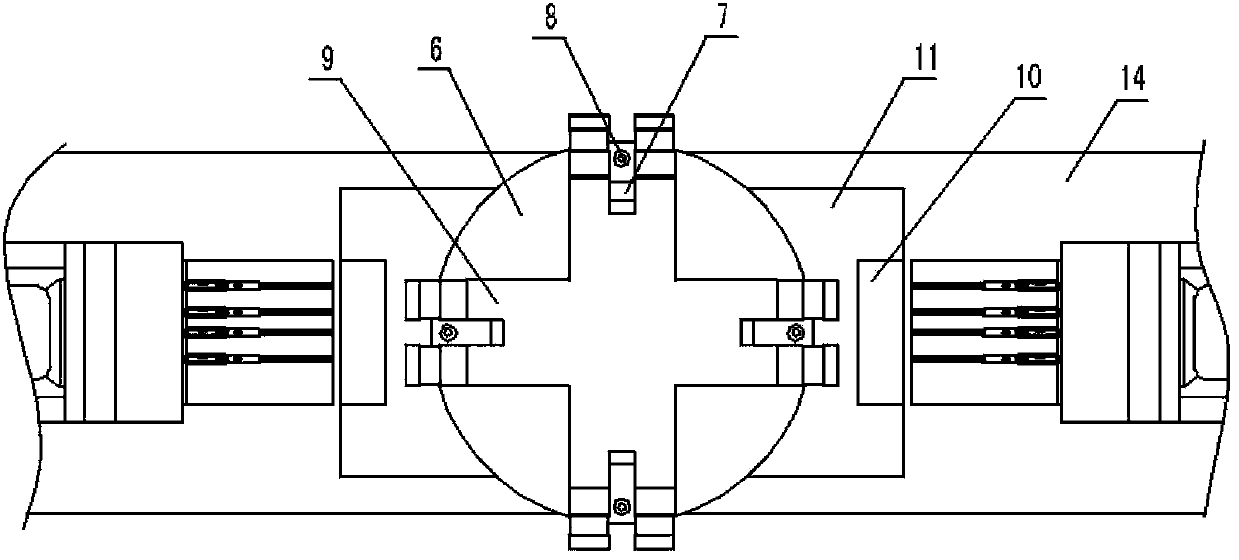

[0014] see figure 1 and figure 2 , the structure of the horizontal two-way multi-head drilling equipment containing the rotary table in this embodiment is set as follows: a motor base 1 is set on the bottom surface of the inner cavity of the middle body 12 of the horizontal two-way machine, and a rotating motor 2 is fixedly installed on the motor base 1. The output shaft 3 of the rotary motor 2 stands upright, and the top of the output shaft 3 is fixedly provided with a rotary table 6, and a plurality of positioning slots for inserting the fixed plate 7 are set on the rotary table 6, and the locking nail 8 passes through the fixed plate 7 and is fixed. The process hole of the workpiece 9 fastens the workpiece 9 on the rotary table 6; the tooling platform 11 is set on the outer periphery of the motor output shaft 3, placed horizontally on the body 14, and the tooling platform 11 is fastened by the fastening nails 4 On the machine body 14; on the drilling tool 10, there is a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com