Waste plastic thin film friction washing machine

A technology of friction cleaning machine and plastic film, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., which can solve leak hole rupture, huge repair and maintenance costs, poor drainage of the cleaning machine casing, etc. problem, to achieve the effect of smooth friction and shifting blades, long friction and cleaning time, and ideal cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific examples.

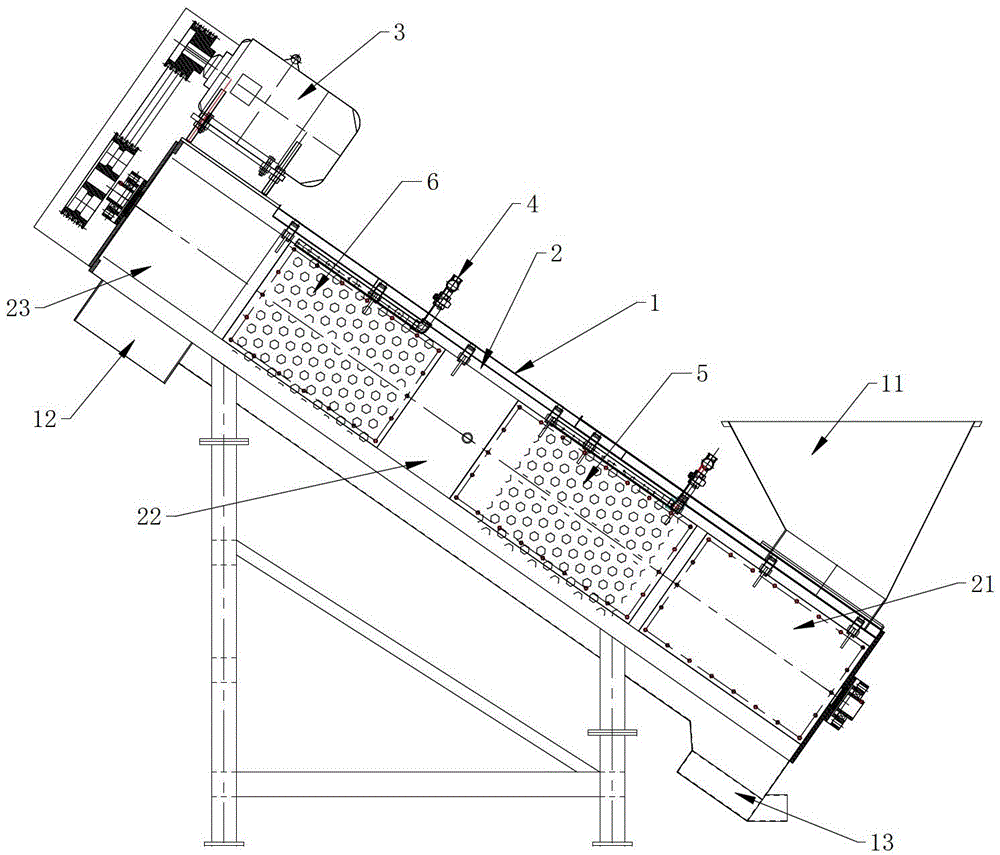

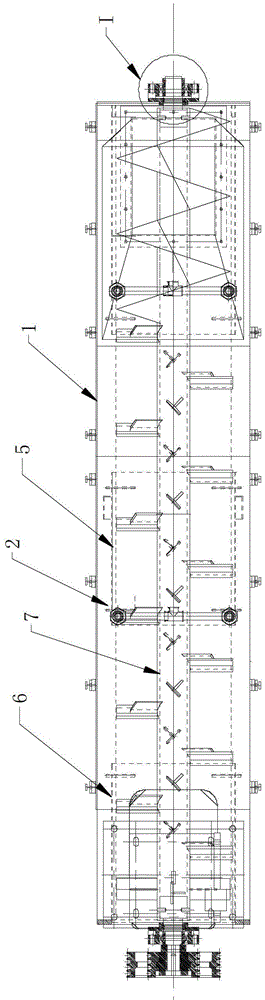

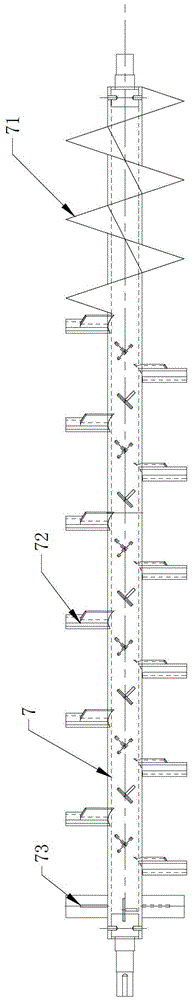

[0022] Such as figure 1 , 2 , 4, a waste plastic film friction cleaning machine, including a casing 1, the arrangement of the casing 1 can be horizontal arrangement, also can be inclined, the arrangement is according to the position of the front and rear equipment of the friction cleaning machine, so that For its connection, the casing 1 is arranged obliquely, and the inner cylinder 2 described later is also arranged obliquely like the casing 1 , and the feed inlet 11 is arranged at the lower end of the casing 1 . One end of the casing 1 is provided with a material inlet 11, the other end is provided with a material outlet 12, the bottom is provided with a sewage outlet 13, the material inlet 11 is arranged on the top of the casing 1, and the material outlet 12 and the sewage outlet 13 are located The bottom of the shell 1, wherein the shell 1 includes a frame, an upper top co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com