Discharge pipe distributing mechanism for powder mixer

The technology of a material distribution mechanism and a material discharge pipe is used in mixers, mixer accessories, dissolving and other directions, which can solve the problem of unfavorable medicinal powder filling the entire hopper, and achieve the effects of easy modification and installation, simple structure and reduced contact amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

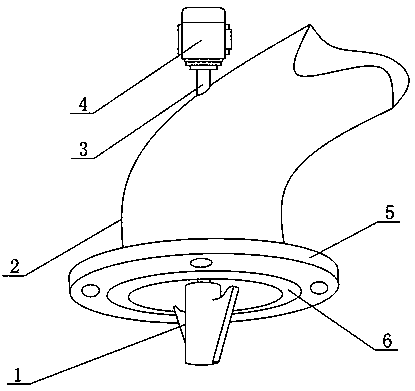

[0019] When the medicine powder is discharged from the mouth of the discharge pipe 2, the distributing head 1 rotates around its rotor driven by the motor 4, and the fin-like structure arranged on the distributing head 1 contacts with the medicine powder during the rotation process, and moves to the The drug powder exerts a force in the same direction as the contact point movement, so that the free fall movement of the drug powder in contact with the fin structure becomes a flat throwing motion during the falling process, which is beneficial to the drug powder to disperse and fall around the distribution head 1; inverted triangle The shape of the fin structure reduces the contact amount of the medicine powder passing through the area of the distributing head and the fin structure of the distributing head, and part of the medicine powder can also fall to the lower part of the distributing head.

[0020] Example 2:

Embodiment 2

[0022] The motor 4 is arranged outside the discharge pipe 2 to prevent the powder from adhering to the outer wall of the motor 4 and affecting the heat dissipation of the motor 4 .

[0023] A flange 5 is also included, and the flange 5 is fixedly connected to the outlet of the discharge pipe 2 .

[0024] The flange plate 5 provided is used for the butt joint between the discharge pipe 2 and other connection pipes, and the flange connection mode is set to facilitate the disassembly and assembly of the discharge pipe 2 and other connection pipes.

[0025] The bottom surface of the flange 5 is also fixedly connected with a rubber pad 6 .

[0026] The provided rubber pad 6 is conducive to easily realizing the sealing between the inside and outside of the pipe at the joint when the discharge pipe 2 is connected to other connecting pipes.

[0027] The connection form between the transmission shaft 3 and the distribution head 1 is threaded connection.

[0028] The threaded connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com