High temperature wire for aerospace and its production process

An aerospace and high-temperature technology, which is applied in the manufacture of conductors, insulated conductors, cables/conductors, etc., can solve the problems of low mechanical strength, high material specificity, poor reliability of conductors, etc., to avoid mechanical damage, excellent comprehensive performance, and anti-cutting performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

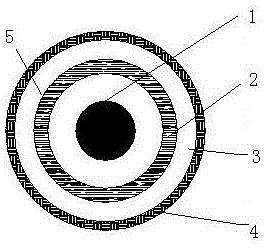

[0031] High-temperature conductors for aerospace use, consisting of nickel-plated copper-clad aluminum flexible stranded wire conductor 5, thin-wall extruded polyetheretherketone inner insulation layer 3, and then seamlessly wrapped long fiber filaments on the polyetheretherketone inner insulation layer Cladding 4 constitutes.

[0032] Long fibers are high-strength continuous filaments. The thickness of the inner insulating layer of polyether ether ketone is 0.10-0.15mm. The nickel-plated copper-clad aluminum flexible stranded wire is composed of a nickel-plated layer 2 on the copper-clad aluminum 1 .

[0033] The production process of high-temperature wires for aerospace, including the following steps:

[0034] 1) Put the nickel-plated copper-clad aluminum flexible stranded conductor core into the combined conductor preheating device in the preheating production line for preheating. The combined conductor preheating device is equipped with 3 heating zones, and the preheatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com