Online detection method of crystal-transformation reaction endpoint in production process of cyclotetramethylene tetranitramine

An Oktokin and reaction end point technology, applied in the field of explosives, can solve problems such as quality accidents, product purity, unstable quality, inaccuracy, timely guidance and optimization of production processes, etc., to ensure quality and overcome time lag Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] This embodiment provides an on-line detection method for the end point of the crystal transformation reaction in the production process of Oktokin, the method includes the following steps:

[0096] Step 1, collect the near-infrared spectrum of the sample:

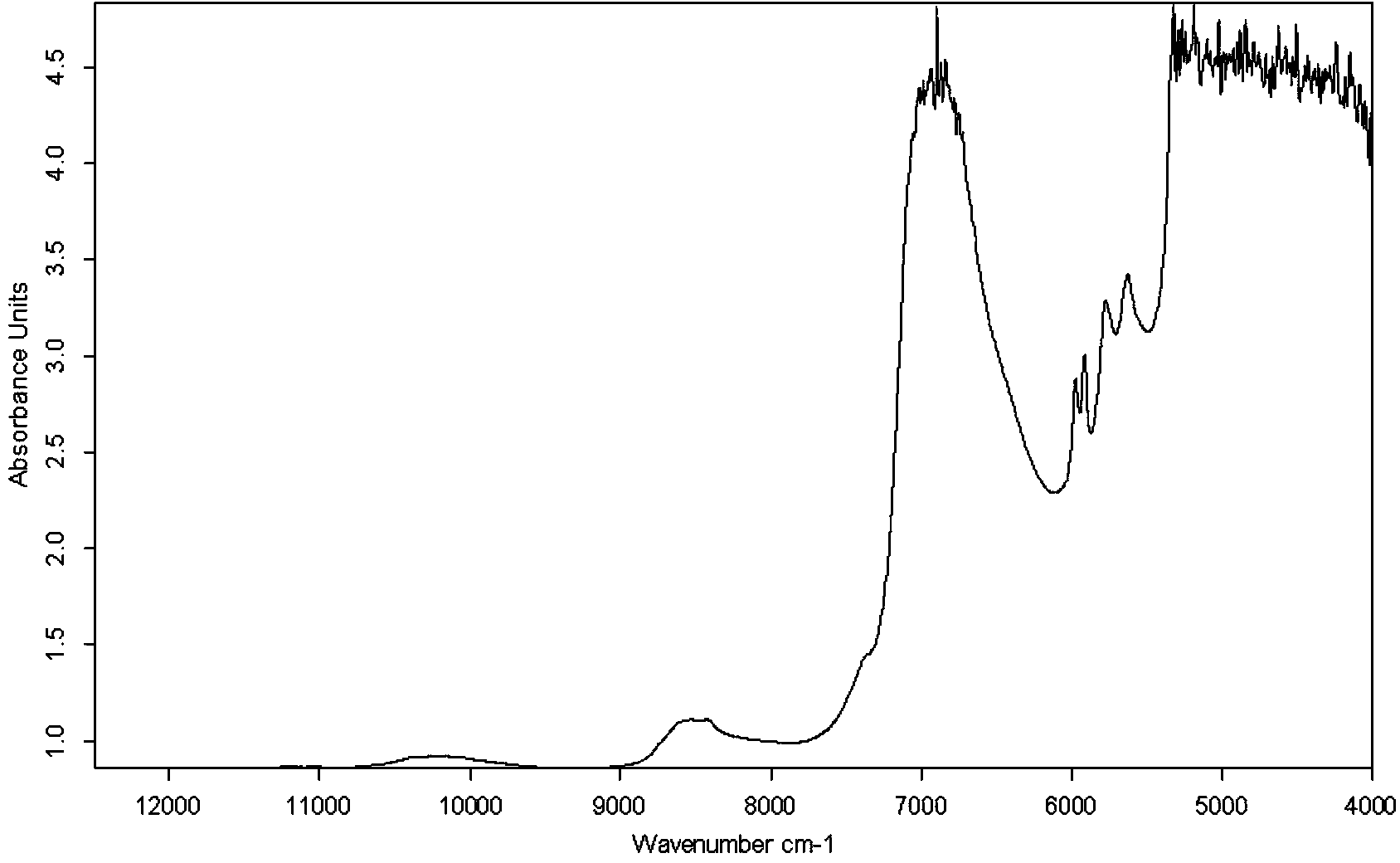

[0097] Take a sample of Octogen known to contain α crystal form in the Octogen transformation reaction system, take a sample of Octogen known to contain α crystal form in the crystal transformation reaction system Near-infrared spectrum scanning is carried out on samples of Octogen-type Octogen, and near-infrared spectrum scanning is performed on samples of Octogen that are known not to contain α crystals. -1 , scan times 32 times, resolution 8cm -1 , to obtain the near-infrared spectrum of the sample known to contain the α crystal form of Octogen as shown in figure 1 As shown, the near-infrared spectrum of a sample of Octogen that is known to be free of α crystal form is obtained as figure 2 , recorded as the or...

Embodiment 2

[0133] This embodiment provides an on-line detection method for the end point of the crystal transformation reaction in the production process of Oktokin, the method includes the following steps:

[0134] Step 1, collect the near-infrared spectrum of the sample:

[0135] The method of step 1 and step 2 in the present embodiment is the same as the method of step 1 and step 2 in embodiment 1, obtains the near-infrared spectrum of the sample known to contain linear ammonium nitrate such as figure 1 As shown, the near-infrared spectrum of a sample known to contain no linear ammonium nitrate was obtained as figure 2 As shown, it is recorded as the original spectrum, and the best modeling interval is obtained.

[0136] Step 3, preprocessing of the original spectrum:

[0137] The standard normal variable transformation is performed on the collected original spectrum to obtain the near-infrared spectrum map after the standard normal variable transformation. The standard normal vari...

Embodiment 3

[0148] This embodiment provides an on-line detection method for the end point of the crystal transformation reaction in the production process of Oktokin, the method includes the following steps:

[0149] Step 1, collect the near-infrared spectrum of the sample:

[0150] The method of step 1 and step 2 in the present embodiment is the same as the method of step 1 and step 2 in embodiment 1, obtains the near-infrared spectrum of the sample known to contain linear ammonium nitrate such as figure 1 As shown, the near-infrared spectrum of a sample known to contain no linear ammonium nitrate was obtained as figure 2 As shown, it is recorded as the original spectrum, and the best modeling interval is obtained.

[0151] Step 3, preprocessing of the original spectrum:

[0152] Carry out any combination of smoothing, differential processing, standard normal variable transformation and multivariate scattering correction to the original spectrum, and the specific smoothing, differenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com