Blackbody components, energy-saving kiln and energy conservation method

A technology for black body components and energy-saving furnaces, which is applied in the field of furnaces and kilns, can solve the problems of inability to guarantee black body components 11, low installation efficiency, poor energy-saving effect, etc., and achieves the effect of solving poor energy-saving effect, quick installation, and improving energy-saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

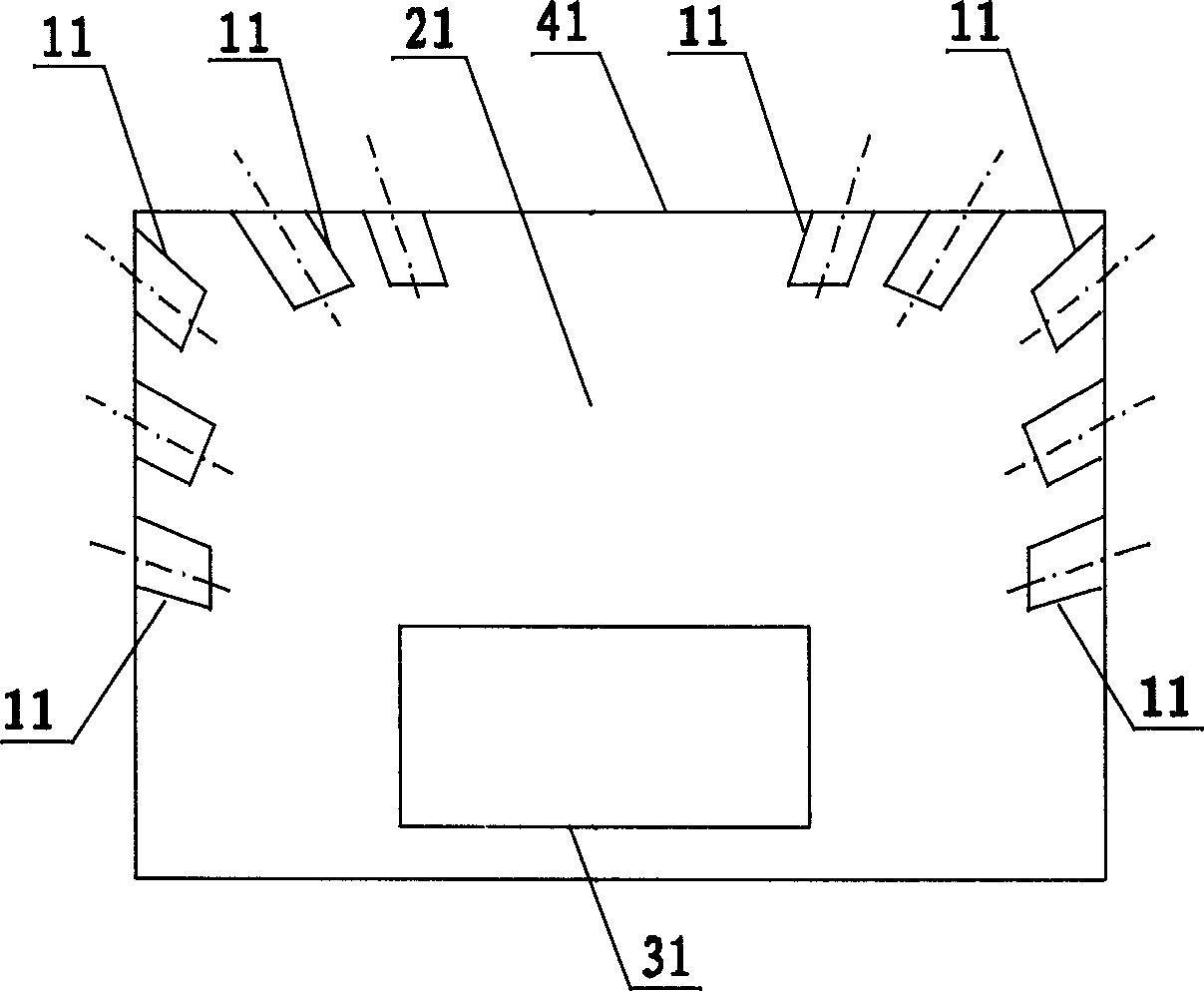

[0036] figure 2 Provided schematically the structural diagram of the energy-saving kiln of the embodiment of the present invention, as figure 2 As shown, the energy-saving kiln includes:

[0037] The furnace wall 41 encloses the furnace 21, and the structure and material of the furnace wall 41 are prior art in the field, and will not be repeated here. The heating workpiece 31 is located in the furnace 21 and occupies part of the space. The furnace wall 41 has a horizontal plane and a vertical plane;

[0038] Black body element 11, the interior of the black body element 11 is hollow, one end pointing to the center of the furnace is an opening, the other end is closed, the closed end (ie, the installation end) is installed on the furnace wall 41, the axis of the black body element or the end face of the open end Keep an inclination with the installation surface of the installation end;

[0039] image 3 Schematically gives a sectional diagram of the installation of blackb...

Embodiment 2

[0046] Figure 5 Provided schematically the structural diagram of the energy-saving kiln of the embodiment of the present invention, as Figure 5 As shown, the energy-saving kiln includes:

[0047] The furnace wall 41 encloses the furnace 21, and the structure and material of the furnace wall 41 are prior art in the field, and will not be repeated here. The heating workpiece 31 is located in the furnace 21 and occupies part of the space. The furnace wall 41 has a horizontal plane and a vertical plane;

[0048] Black body element 11 , the interior of the black body element 11 is hollow, one end pointing to the center of the furnace 21 is open, and the other end is closed, and the closed end is installed on the furnace wall 41 .

[0049] Figure 6 Schematically provides a schematic cross-sectional diagram of the installation of the black body element of the embodiment of the present invention, as Figure 6 As shown, the mounting ends of at least two (such as 4, 6 or 9, etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com