A method for manufacturing a large-diameter wear-resistant and corrosion-resistant ternary composite variable diameter pipe

A ternary composite and manufacturing method technology, applied in pipeline protection, pipeline anti-corrosion/rust protection, pipeline damage/wear prevention, etc., can solve the problems of single performance, weak binding force, short life, etc., and achieve long service life, Strong adhesive force, solve the effect of short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

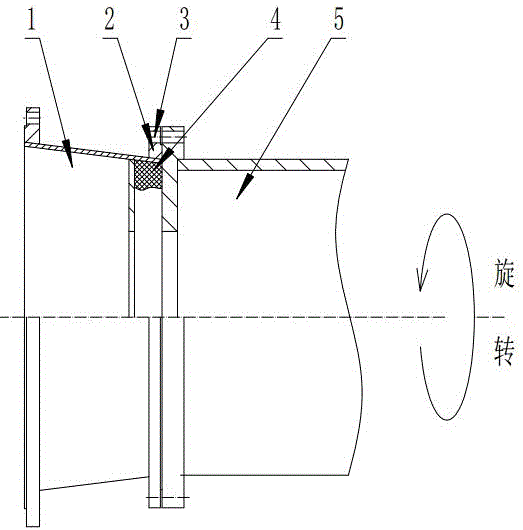

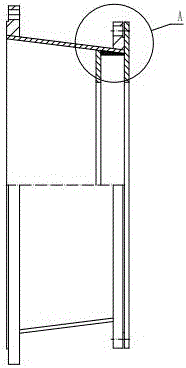

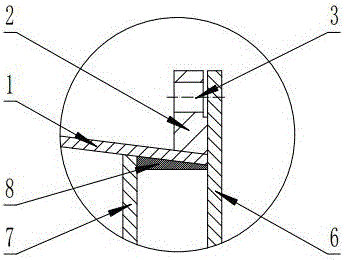

[0042] Example 1: This method is used to manufacture DN700-DN600 variable diameter pipes with a length of 200 (unspecified units are mm, the same below)

[0043] a. Use the gradient method to carry out the self-propagating high-temperature centrifugal synthesis reaction on the variable-diameter tube step by step. The steps are as follows:

[0044] The outer diameter of the large end of this large-diameter variable diameter tube is 720, the outer diameter of the small end is 630, the wall thickness is 14, the inner diameter of the large end is 692, the inner diameter of the small end is 602, and the difference between the inner diameters of the large and small ends is 90. The difference in diameter is 18 (unilateral Difference 9) is the gradient interval, which can be divided into 5 sections (segments), then the axial length of the variable diameter tube is 200, and after being divided into 5 sections, each section is 40, and the diameter of each section in the middle of the var...

Embodiment 2

[0053] Example 2: This method is used to manufacture a DN1200-DN1000 variable diameter pipe with a length of 400 (unspecified units are mm, the same below)

[0054] a. Use the gradient method to carry out the self-propagating high-temperature centrifugal synthesis reaction on the variable diameter tube in sections and steps. The steps are as follows:

[0055] The outer diameter of the large end of this large-diameter variable diameter tube is 1220, the outer diameter of the small end is 1020, the wall thickness is 14, the inner diameter of the large end is 1192, and the inner diameter of the small end is 992. Difference 12.5) is the gradient interval, it can be divided into 8 sections (sections), the axial length of the variable diameter tube is 400, and the length of each section after being divided into 8 sections is 50, and the diameter of each section in the middle of the variable diameter tube is: 1167, 1142, 1117 , 1092, 1067, 1042, and 1017, respectively make 7 retainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com