Composite iron roughneck and slurry blowout prevention box

An iron driller and blowout preventer technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of prolonged operation time, reduced operation efficiency, and compression of safe space around the wellhead, so as to reduce operation time and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

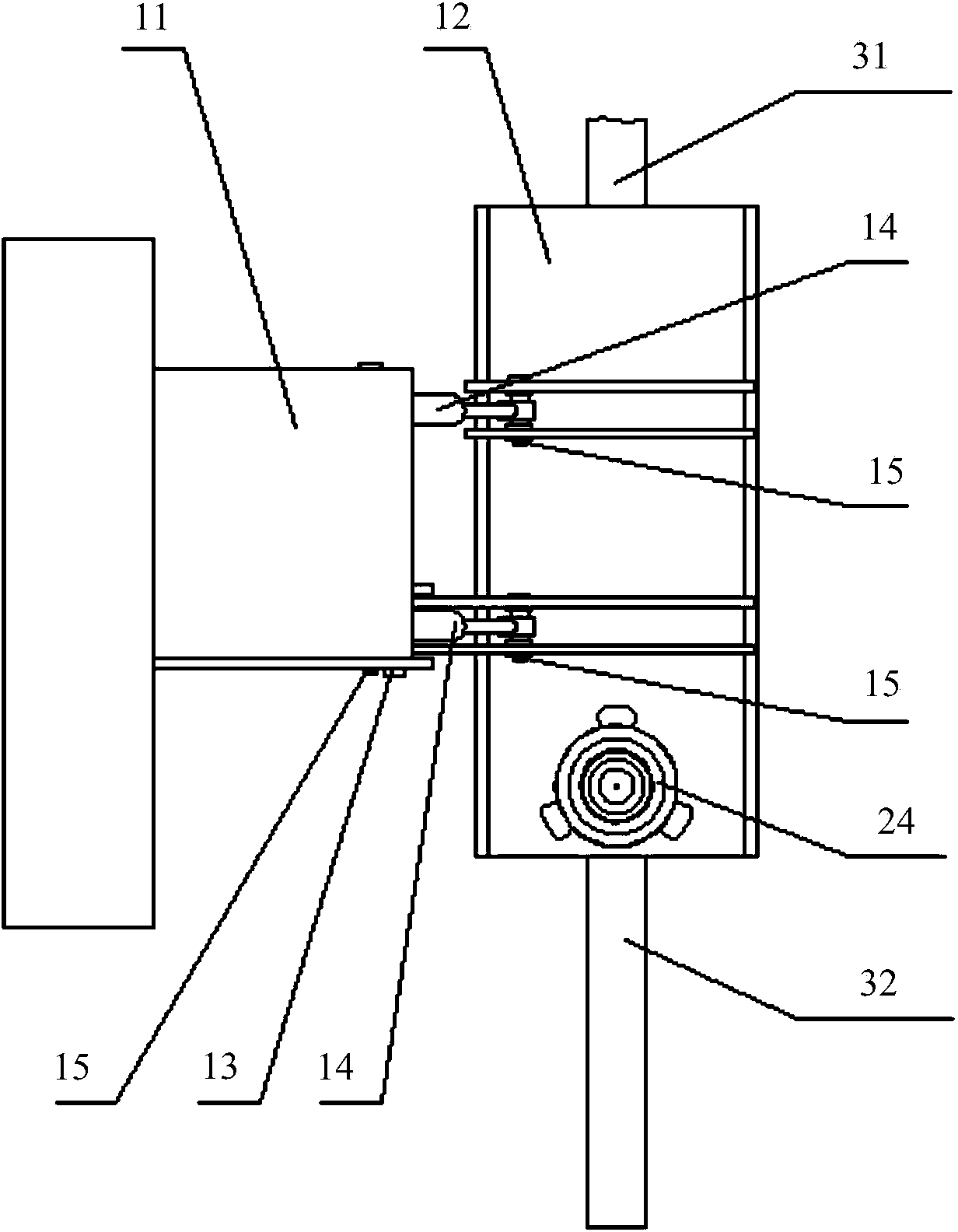

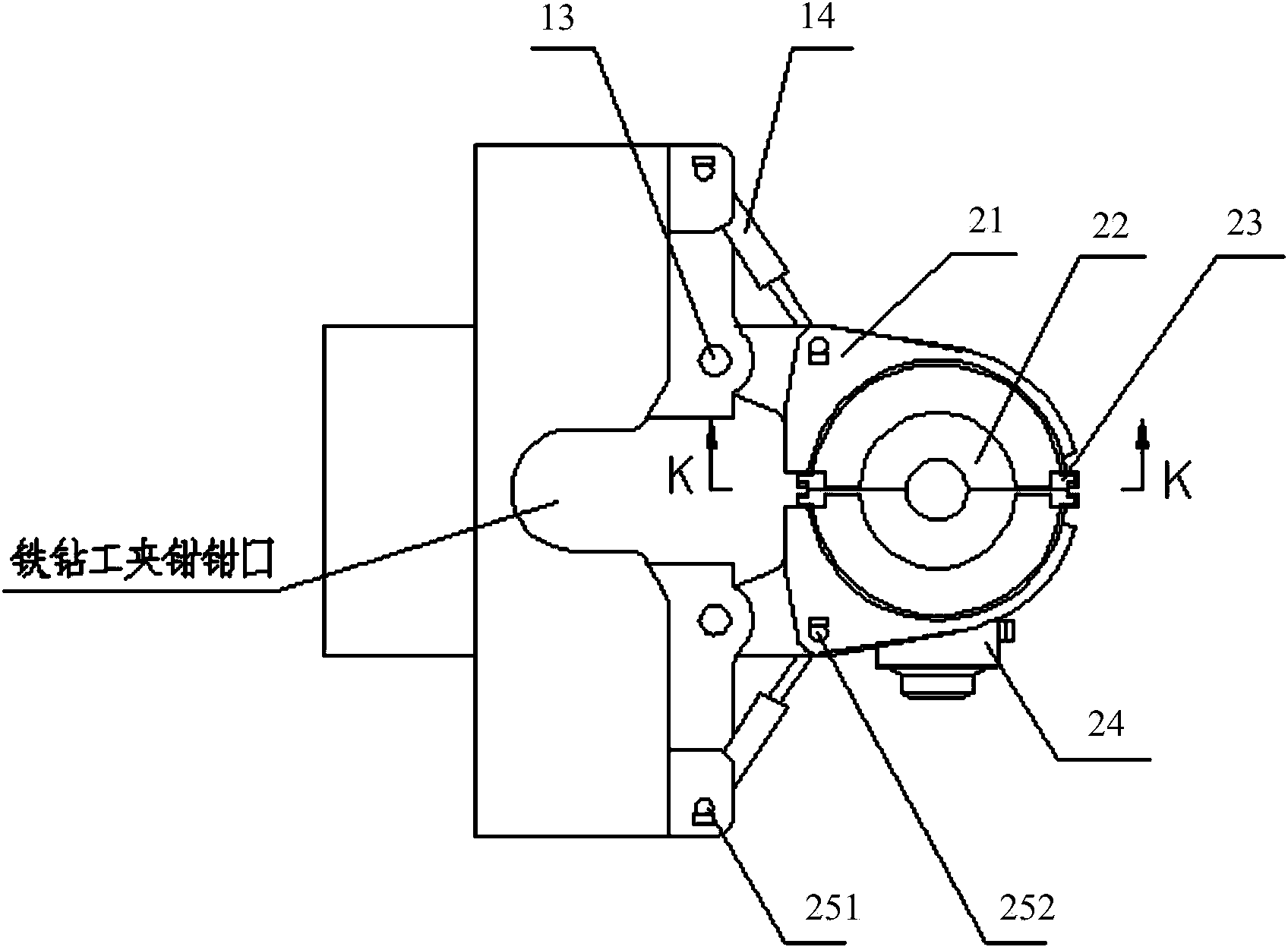

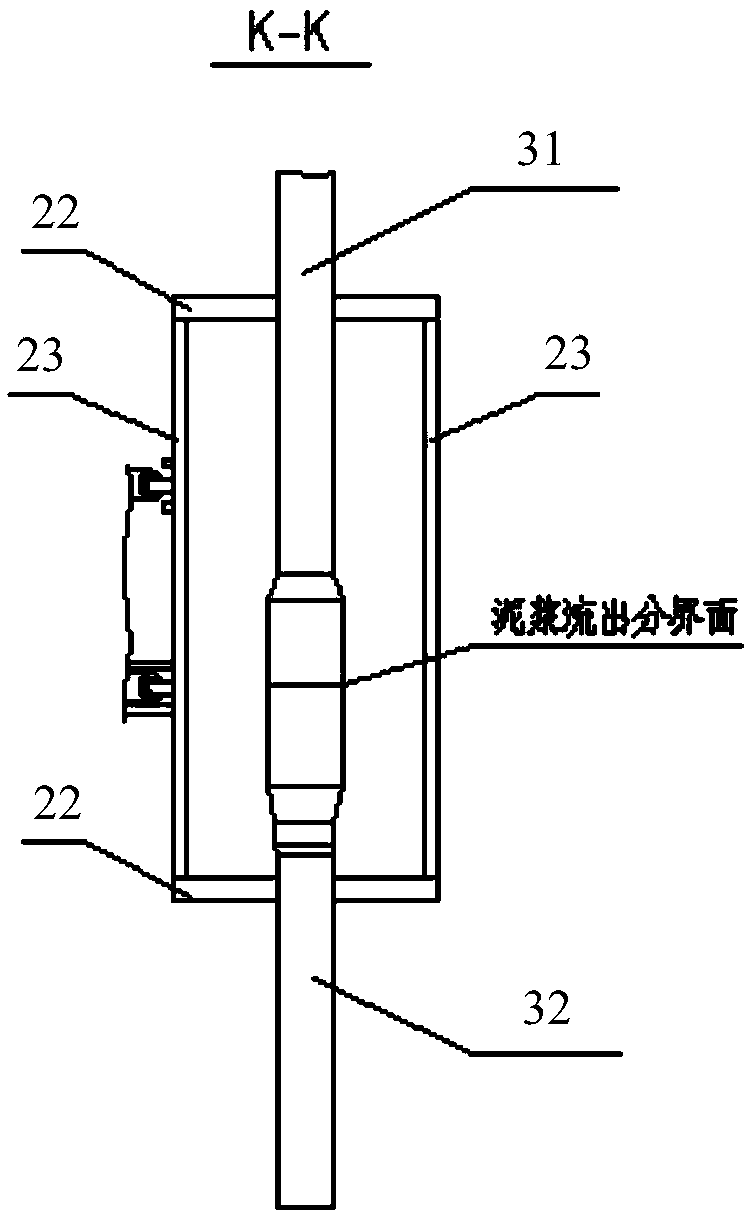

[0019] refer to Figure 1 to Figure 3 , The composite iron driller and mud blowout prevention box of the present embodiment include: iron driller 11, mud blowout prevention box 12, connecting pin 13, oil cylinder 14 and oil cylinder pin 15. The mud blowout prevention box 12 includes: a box body 21 , a sealing member 22 , a sealing strip 23 and a union 24 .

[0020] Wherein, the box body 21 includes two half-box bodies that cooperate with each other, in this embodiment, it is two half-cylindrical bodies, but it is not limited thereto. Correspondingly, the seal 22 is two half-circular plates mounted on the top and bottom of two half-cylinders. More specifically, semicircular annular seals 22 are installed up and down inside the two semi-cylindrical bodies of the mud bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com