Automated power ramp

A power and ramp technology, applied in drill pipes, casings, drill pipes, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of short lifting distance, high efficiency, and reduced manual operation intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The automatic power ramp of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

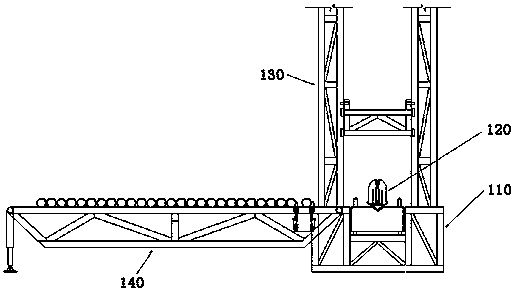

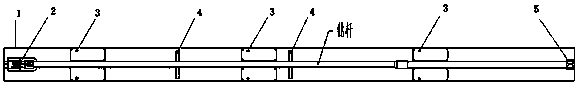

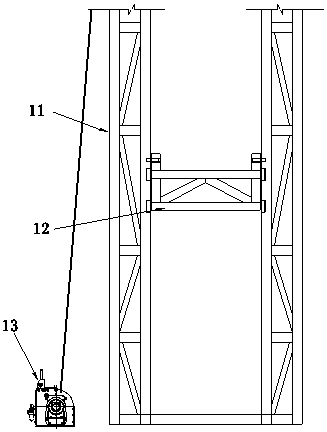

[0015] like figure 1 As shown, the automatic power ramp is composed of a base mechanism 110, a power catwalk mechanism 120, a lifting guide rail 130 and a drill rod rack mechanism 140; The moving device slides on the guide rail; the air winch is connected with the power catwalk mechanism 120 to provide power for the power catwalk mechanism; the power catwalk mechanism 120 is arranged on the sliding device, and can slide through the sliding device on the base. , and the bracket on the lifting guide rail 130 is fixed with a fixed pin, and can be rotated along the pin shaft during the ascent process; the drill rod rack mechanism 140 is connected with the pin shaft of the base, and is supported on the ground through the lifting hydraulic cylinder; the lifting guide rail 13-and the base The flange plate is fixed by a fixed pin,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com