All-cross-section cutting rectangular pipe-pushing machine cutting mechanism

A technology of cutting mechanism and pipe jacking machine, which is applied in the direction of drilling without stripping topsoil, etc., can solve the problems of low reliability, low ability to get out of trouble, and difficult construction, so as to reduce the incidence of accidents, improve the ability to get out of trouble, and reduce manufacturing. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

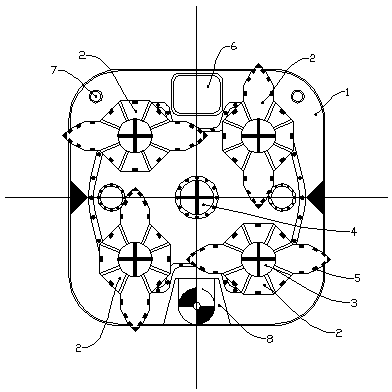

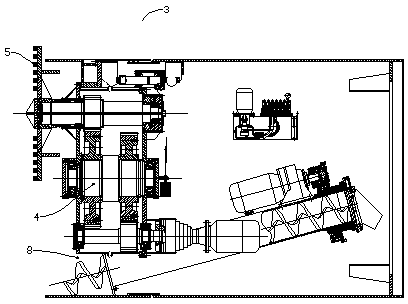

[0022] As shown in the figure, the cutting mechanism of the full-section cutting rectangular pipe jacking machine includes a mounting seat 1, and four cutter heads 2 with cutting surfaces on the same plane are installed on the front face of the mounting seat; the centers of the rotating shafts 3 of the four cutter heads are respectively Located on the four vertices of a square, and driven by the same spindle 4 located in the center of the mounting seat to rotate synchronously and at a constant speed; the end surface profile of the cutterhead 2 is elongated with a dimension in the length direction greater than that in the width direction, and the edges of the cutterhead 2 are arranged There are cutting edges 5; the length direction of each cutter head 2 is perpendicular to the length direction of the adjacent cutter head, and the maximum cutting radius of each cutter head 2 overlaps with the maximum cutting radius of the adjacent cutter head, There is no interference when the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com