Secondary connector for construction installation and construction installation structure

A technology for secondary connection and installation, applied in building components, building structures, buildings, etc., can solve the problems of sagging connection hole gaps, hidden safety hazards of de-soldering, and difficulty in work, so as to increase connection strength and improve installation safety. The effect of saving installation labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

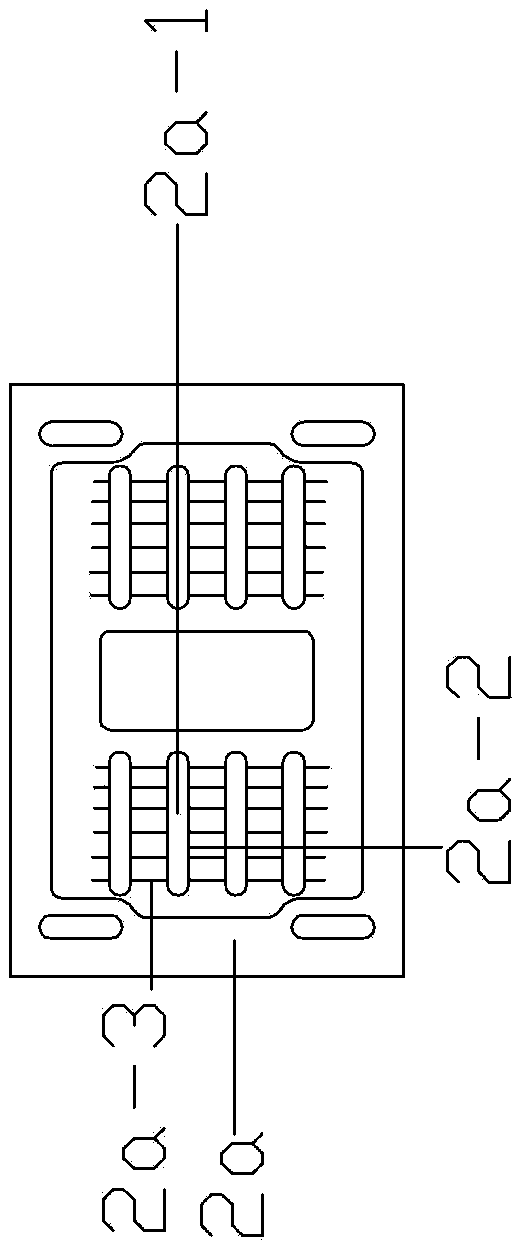

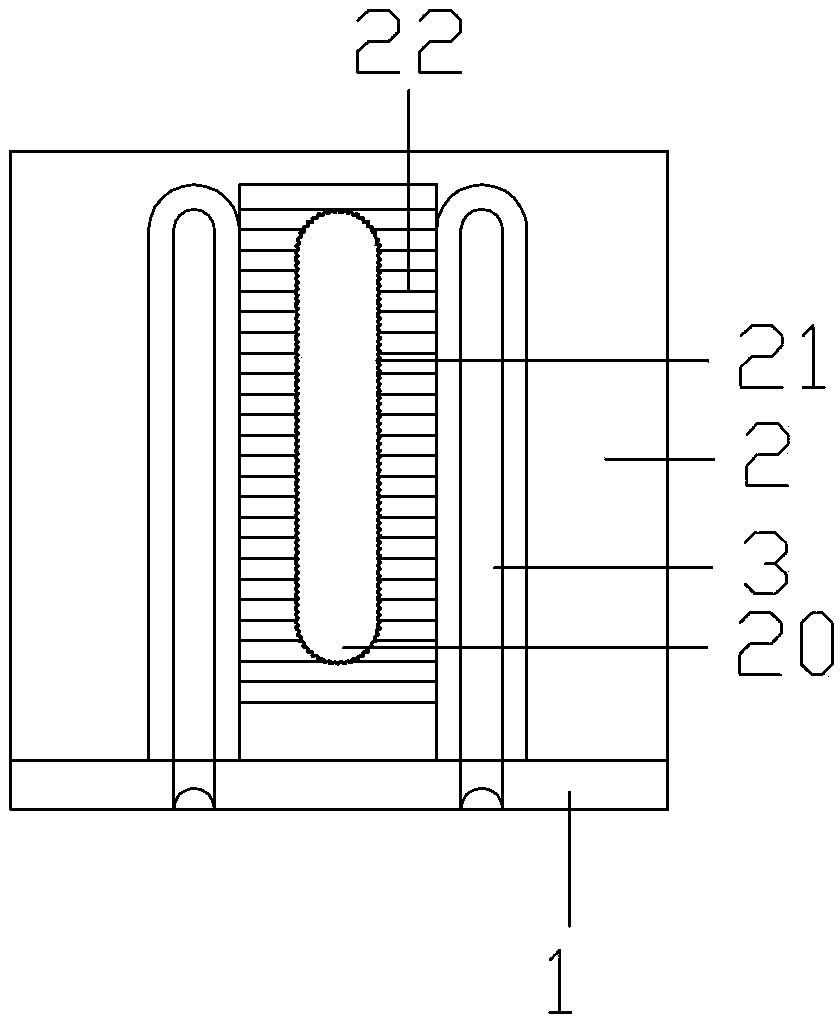

[0047] Refer to attached picture. The secondary connector A for building installation provided by the present invention is composed of a first mounting plate 1 and a second mounting plate 2 arranged at right angles, and the first mounting plate 1 and the second mounting plate 2 There are long connecting holes 10, 20 on the top, and a ring of internal teeth 11, 21 are provided along the wall of the long connecting holes, and there is a concave-convex positioning configuration for positioning anti-slip on the surrounding surface of the hole corresponding to the pressing part of the fastener. 12, 22.

[0048] There are reinforcing ribs 3 on the first mounting plate, the second mounting plate and the right-angled corners.

[0049] The direction of the long connecting holes 10, 20 can be determined according to the direction in which the position needs to be adjusted.

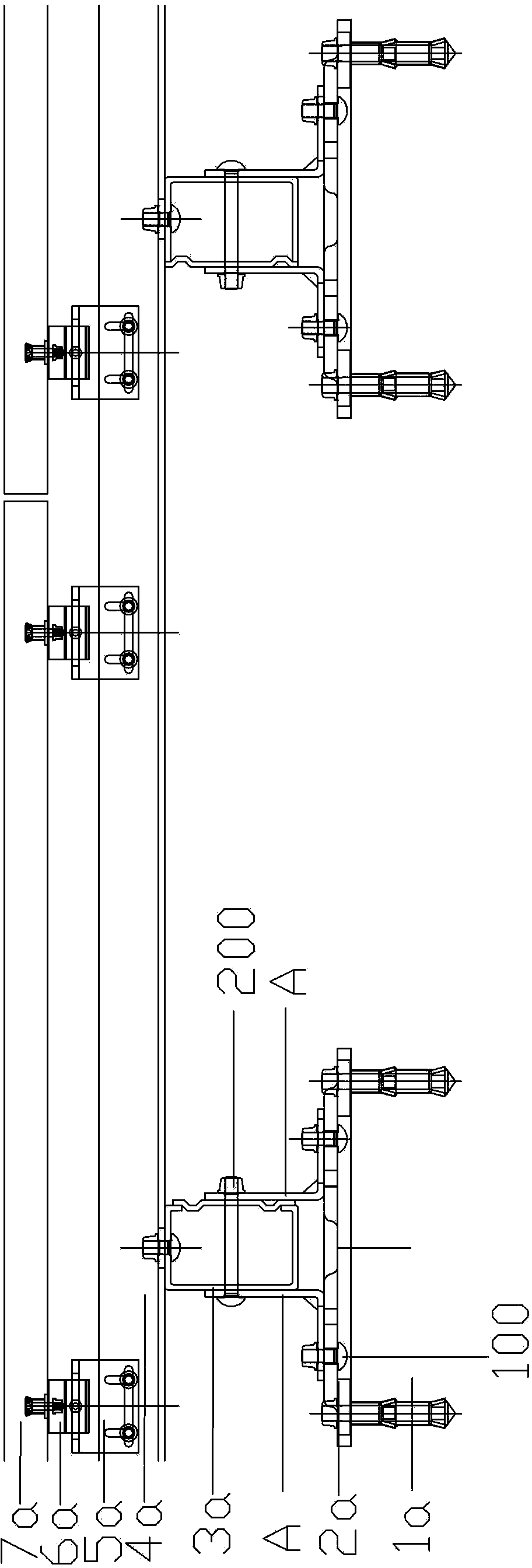

[0050] Such as figure 1 In the curtain wall installation system shown, the labels of each component are: 1a, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com