Underflow energy dissipation structure for fish back type drop bank

A technology for energy dissipation of undercurrent and fish back, which is applied in water conservancy engineering, marine engineering, coastline protection, etc., can solve problems such as building damage and surrounding environmental impact, and achieve the effects of high safety, mitigation of threats, and reduction of pulsating pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 represents the case where the first-stage discharge tank adopts a multi-stream discharge mode, that is, a multi-stream outflow mode, and the second-stage fish-back discharge tank adopts a continuous type.

Embodiment 2

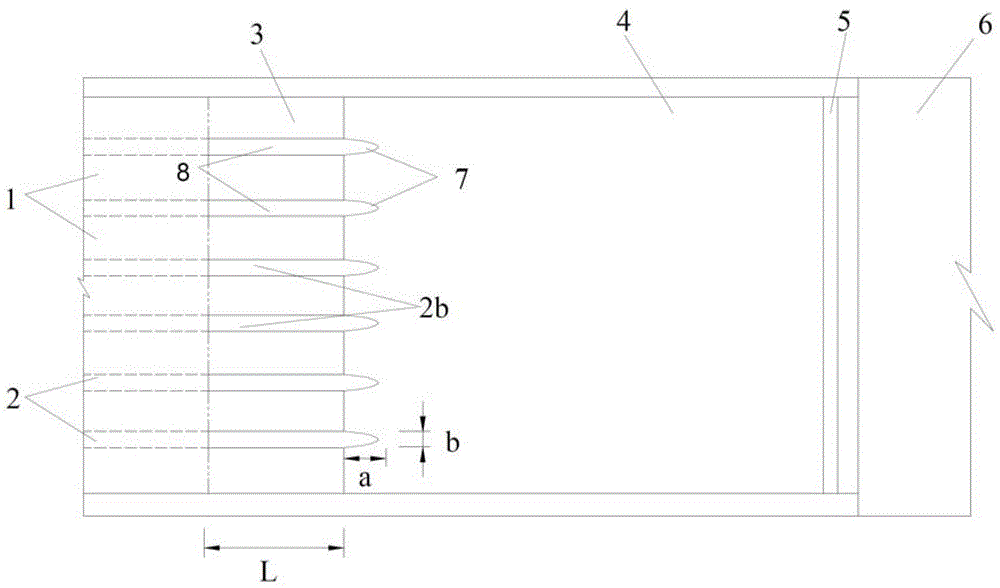

[0047] Embodiment 2 represents the case where the first-stage discharge tank adopts a multi-stream discharge mode, that is, a multi-stream outflow mode, and the second-stage fish-back discharge tank adopts an interval type.

[0048] These embodiments are also applicable to the continuous discharge mode of the upstream discharge tank (primary discharge tank), that is, the continuous outflow mode.

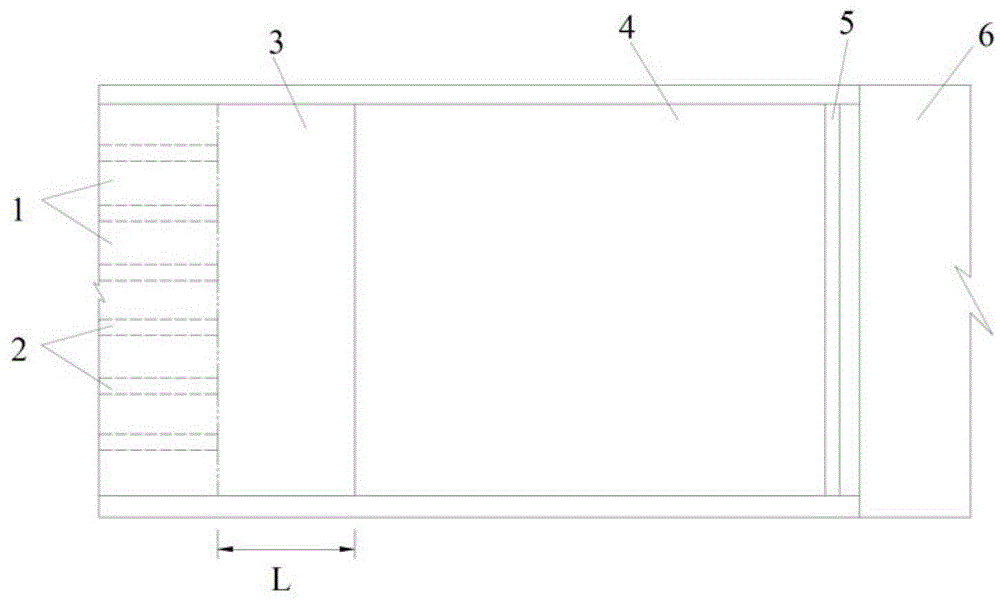

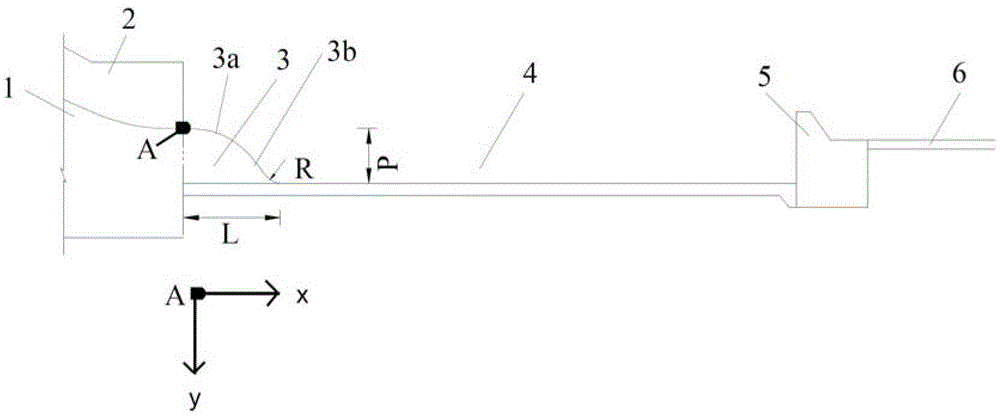

[0049] In Example 1, see figure 1Shown is a schematic plan view of the structure of the fish-back type falling sill and bottom flow energy dissipator in Example 1. The present invention provides a new type of fish-back type falling sill and bottom flow energy dissipation structure. , the chute partition wall 2, the secondary fish-back chute 3, the stilling pool 4, the tail sill of the stilling pool 5 and the downstream apron 6.

[0050] Wherein, the secondary fish-back type discharge tank 3 adopts a continuous type, the front end of the secondary fish-back type discharge tank 3 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com