A kind of circulation system device of closed frame electrolytic nickel or electrolytic cobalt electrolyte

A circulation system and electrolyte technology, applied in the electrolysis process, electrolysis components, photography technology, etc., can solve the problems of poor sealing effect of the gas collecting hood, difficulty in uniform discharge of acid mist, and influence on the amount of electrolyte, etc., to shorten the distance between the same poles , Save labor, change the effect of bad environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

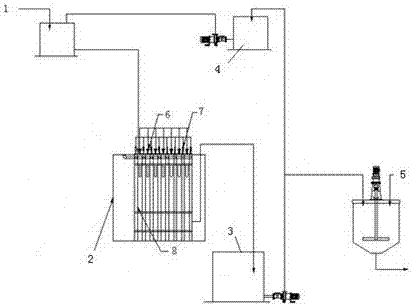

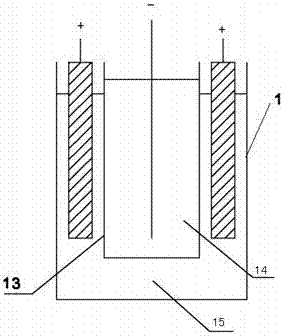

[0029] like figure 2 As shown, the circulation system device of electrolytic nickel or electrolytic cobalt electrolyte is firstly provided with 34 cathode frames and 35 anode frames in the electrolytic cell, the distance between the anode and the cathode is 100mm, and the cathode frame and the anode A permeable membrane of model 3751 is set between the frames, the anode plate is placed in the anode frame, the cathode plate is placed in the cathode frame, the electrolyte inlet is set on the cathode frame, the anolyte outlet is set at the lower end of the anode frame, and the anode frame The acid mist discharge port is set at the upper end, and the catholyte inlet of the high level tank is set at the other end of the electrowinning cell. The anode frame is a closed structure, and the acid mist generated in the anode frame is uniformly discharged and collected through the acid mist discharge port. The collected acid The fog is treated uniformly by ventilation.

[0030] The flow...

Embodiment 2

[0032] The device structure adopts the structure in Example 1, only the number of cathode frames in each electrowinning cell is 48, the number of anode frames is 49, and the distance between the cathode frames and the anode frames is 70mm.

Embodiment 3

[0034] The structure of the device adopts the structure in Example 1, only the number of cathode frames in each electrowinning cell is 85, the number of anode frames is 86, and the distance between the cathode frames and the anode frames is 40mm.

[0035] Comparative example 1:

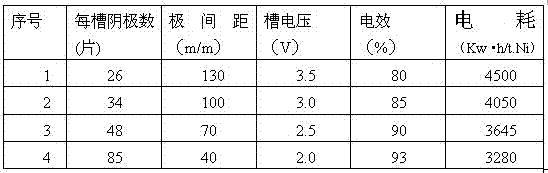

[0036] In the same device, a traditional electrowinning device is used. The number of cathodes in each cell is 26, and the electrode spacing is 130mm. The electrowinning test results of different electrode spacings are measured, and the cell voltage, electric efficiency and power consumption in the experimental results are analyzed. analyze:

[0037]

[0038] In the same electrowinning cell, it can be seen from the above table that the smaller the electrode spacing, the lower the cell voltage, the higher the electric efficiency, and the lower the power consumption. Therefore, the use of this device can save production costs.

[0039] Based on the existing 188 electrolytic cells and 330 working day...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com