Efficient regeneration desulphurization tower

A high-efficiency regeneration and desulfurization tower technology, applied in the field of desulfurization tower and desulfurization tower desulfurization process, can solve the problems of low corrosion resistance, frequent equipment shutdown and maintenance, and decreased desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

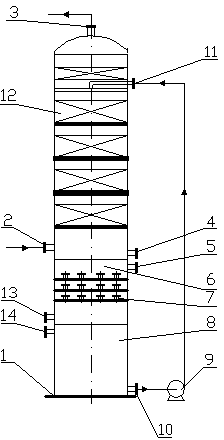

[0013] Attached below figure 1 The present invention is further described.

[0014] The bottom of the lower part of the desulfurization tower main body 1 is a lean liquid tank 8, and a lean liquid outlet 10 and a sulfur foam outlet 14 are opened in this section. Packing 12 is installed in the desulfurization section of the tower, and a set of regenerator 6 is installed on the upper part of the lean liquid tank 8. A solution circulation pipeline is installed outside the body, and a solution circulation pump 9 circulates the solution inside and outside the tower through the lean solution inlet 11, the rich solution outlet 4, the rich solution inlet 5, and the lean solution outlet 10. The process flow is that the crude gas from the cold drum electric capture section enters the gas inlet 2 from the main body of the desulfurization tower and enters into the countercurrent contact washing with the desulfurization liquid sprayed from the top of the tower. Under the action of the cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com