Continuous production reaction device and continuous production reaction method for N-(beta-aminoethyl)-gamma-aminopropyltrimethoxysilane

A technology of aminopropyltrimethoxysilane and reaction device, which is applied in the field of silane coupling agent, can solve the problems of reducing output, increasing consumption, increasing product consumption, etc., so as to reduce labor intensity and amount of labor, increase reaction rate, and simplify The effect of applying steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

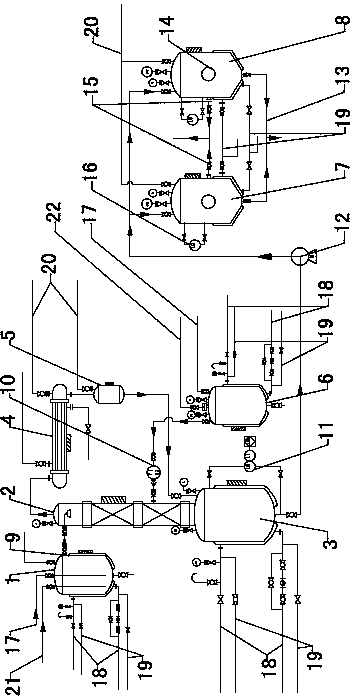

[0039] 1. Vaporization of ethylenediamine: pump the raw material ethylenediamine into the ethylenediamine vaporization kettle 6, raise the temperature to 120°C, control the pressure of the kettle to 0.06MPa, open the inlet valve of the tower ethylenediamine vaporization liquid and control it through the flowmeter 10 The flow rate is 150 Kg / h; observe the ethylenediamine reflux in the gas-liquid separator 5, open the reflux valve of the reactor 3; slowly raise the temperature of the reactor 3 to 150°C; control the top temperature to 121°C, and the bottom temperature to 150°C;

[0040] 2. Premix: Pump ethylenediamine and 400 Kg chloropropyltrimethoxysilane into the premix kettle 1 respectively by the pump, and the mixed solution enters the reaction tower 2 from the overflow port 9, and the ethylenediamine and chlorine The pumping rates of propyltrimethoxysilane are 45Kg / h and 100Kg / h respectively;

[0041] 3. Continuous discharge at the bottom of the tank: Observe the reaction l...

Embodiment 2

[0045] 1. Vaporization of ethylenediamine: pump the raw material ethylenediamine into the ethylenediamine vaporization kettle 6, raise the temperature to 120°C, control the pressure of the kettle to 0.07 MPa, open the inlet valve of the tower ethylenediamine vaporization liquid and control it through the flowmeter 10 The flow rate is 145Kg / h; observe the ethylenediamine reflux in the gas-liquid separator 5, open the reflux valve of the reactor 3; slowly raise the temperature of the reactor 3 to 150°C; control the top temperature to 120~122°C, and the bottom temperature to 150~152°C ;

[0046] 2. Premix: Pump ethylenediamine and 400 Kg chloropropyltrimethoxysilane into the premix kettle 1 respectively by the pump, and the mixed solution enters the reaction tower 2 from the overflow port 9, and the ethylenediamine and chlorine The pumping rates of propyltrimethoxysilane are 48Kg / h and 100Kg / h respectively;

[0047] 3. Continuous discharge at the bottom of the tank: Observe the ...

Embodiment 3

[0051] 1. Ethylenediamine vaporization: pump the raw material ethylenediamine into the ethylenediamine vaporization kettle 6, raise the temperature to 120°C, control the pressure of the kettle to 0.08 MPa, open the inlet valve of the tower ethylenediamine vaporization liquid and control it through the flow meter 10 The flow rate is 155 Kg / h; observe the ethylenediamine reflux in the gas-liquid separator 5, open the reflux valve of the reactor 3; slowly raise the temperature of the reactor 3 to 150°C; control the top temperature to 122~123°C, and the bottom temperature to 152~153°C ℃;

[0052] 2. Premix: Pump ethylenediamine and 400 Kg chloropropyltrimethoxysilane into the premix kettle 1 respectively by the pump, and the mixed solution enters the reaction tower 2 from the overflow port 9, and the ethylenediamine and chlorine The pumping rates of propyltrimethoxysilane are 42Kg / h and 100Kg / h respectively;

[0053] 3. Continuous discharge at the bottom of the tank: Observe the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com